Home > Products > Cereal corn Flakes machine > Fully automatic Kelloggs corn flakes and baby breakfast cereal manufacturing plant

Fully automatic Kelloggs corn flakes and baby breakfast cereal manufacturing plant

- 10 Set / Sets per Month

- QINGDAO

- T/T Credit Card

You May Like

-

Automatic prawn cracker processing line

-

Nutrition powder processing line

-

Automatic testing double-screw extrusion snacks processing line

-

Fried pasta processing line

-

Environmental degradable damping packing material processing line

-

Animal Pet Food Production Line /Dog Food Machine /Automatic modified starch

Product Details

| Brand Name | saixinmachinery | Place of Origin | Shandong, China | |

| Model Number | DSDZ series | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

China corn flakes machine, China corn flakes machine supplier

Fully automatic Kelloggs corn flakes and baby breakfast cereal manufacturing plant

................................................................................................................................................

Brief introduction and functions of corn flakes processing line:

............................................................ .....................................................................................................................

Breakfast cereal corn flakes production line is a fully automatic producing line which is developed from that

DG combined with European advanced technology.The corn flakes processing line uses crn flour,oat,buckwheat,etc

as raw material , can intensify vitamin and mineral substance.It also can add little cocoa and powdered sugar,add water

mix evenly with twin screw extruder to accomplish cook curing,pelleting etc process.Then through pressing,toasting ,

coating etc technological process ,it can produce sweet taste or salty crispy instant breakfast cereals corn flakes.

It is a breakthrough to solve the problems regarding to sticky material on the roller,low output of flakes pressing,

low shaping rate,poor taste and so on.

Scientific manufacturing rechnique ,can keep the nutritional ingredient of the cereals and natural flavor in good contidion .

Reasonable equipments collocation adn realize process contrl ensure high quality an delicious conr flakes production.

The processing line not only reduces costs by improving efficiency ,but also improves market competitiveness.

This production line is a Multifunctional and muti-purpose production line.

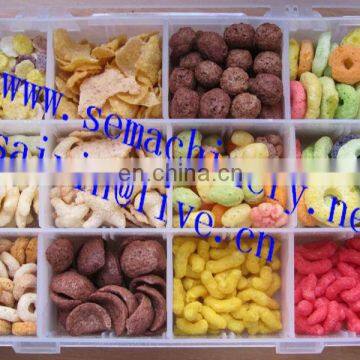

It not only can produce different shapes breakfast cereal corn flakes ,but also can produce corn puffed

snacks food, pet food ,artificial rice etc which not need to add any additional equipments.

Technical processing flow:

.............................................................................................................................................................................

Raw material mixing→elevating→extrusion→vibrating cooler→flakes pressing→vibrating cooler→Pre-drying→

→High temperature drying→sugar coating and flavoring→drying→cooling→packaging

CAD Drawing of corn flakes processing line (example: 300-350kg/h) :

jinan saixin good quality corn flakes processing machine, corn flakes processing machinery

kellogg's corn flakes machine,corn flakes machine manufacturer ,corn flakes machine,corn flakes making machine,kellogs corn flakes production line

Specifications

corn flakes production line

Corn flakes machine

1. corn flakes twin screw extruder

2. Flakes, cereals, snacks machine

3. Corn flour as raw materials

Corn flakes machines, breakfast cereal machine

1. Description: Corn flakes are a popular breakfast cereal manufactured by twin-screw extruder or single screw extruder through the treatment of flakes of grain, served with milk and marshmallows, were a very popular food among the families.

2. Raw materials: adopts maize,wheat,oats, corn flour as raw materials

3. Products: This line can be used to produce corn flakes, breakfast cereals, snacks by adjusting the moulds from extruder

4. Capacity: 150kg/h, 200-300kg/h,400-500kg/h

5. Machines Materials: All the machines are made by stainless steel

5. Features:

No.1: Production Flow-chart

Raw material mixing→ mixed material elevating→extrusion process→librating cooler→ single drum →air conveyer →presser →librating cooler→air conveyer →dryer →librating cooler →air conveyer→high temperature oven →librating cooler →elevator→sugar sprayer→dryer →cooler

No.2: characteristics of corn flakes production line

This processing line is developed and improved on the base of Italian technology. Its working standard can compare to European machines

1.Twin screw extruder is the host machine in this line. The unique design of twin screw is an innovating idea of our engineers; it guarantees the success of the extrusion process.

rn flaker

is an important part of this line; the design makes sure high quality products can be produced. It contains a material distributor for avoiding materials geminated. The two rollers for pressing materials are made of high rigidity metal. It also has automatic chilling system and can be adjusted very easily. This equipment is easy using and highly automated.

3. The corn flakes roaster or Hot air heater

which is a new idea of processing corn flakes. This technique is by using high temperature airs centralized heat and circulating flow to process corn flakes quickly and easily. This method is also less power consumption. This innovating idea makes this processing line one step ahead of our competitors who are still using salt heater to do the job. There are many disadvantages using salt as a medium to puff corn flakes such as salt powder will be covered on the corn flakes, more power consumption and long time processing.

corn flakes roaster : by using high temperature air (300-400°C) to heat materials in a short time in order to make them more puffed. The reason for using high temperature air is that materials can be heated evenly and quickly, also the air can be used in a cycle.

This corn flakes roaster is a key equipment in the corn flakes line, its core technology is from Italy, Air Heater using high temperature air as medium to expand the corn flakes evenly without any pollution. As some manufactures are still using salt as the medium to expand corn flakes, in that way the taste of the corn flakes will be corrupted by the salt and the corn flakes can not be puffed evenly the taste is crunchy, also during using salt as the medium for expanding products will have lots of fogs out of the machine and it can rust other steel equipments.

Jinan saixin are leader and professional manufacturer for jinan saixin machinery co corn flakes production line,corn flakes extruder,kellogs corn flakes,corn flakes processing line,nestle corn flakes,corn flakes factory,cereal corn flakes,corn flakes processing machinery,corn flakes plant,corn flakes manufacturers,corn flakes equipments, corn flakes manufacturing plant,corn flakes packing machine,roasted corn flakes processing line,corn flakes food machine,corn flakes packaging machine,corn flakes manufacturing machine,cereal corn flakes machinery,corn flakes manufacturing equipments,cereal corn flakes making machine,breakfast cereal/corn flake production line,corn flakes breakfast cereal machines,breakfast cereal corn flakes machines,corn flakes production machine,breakfast cereal/corn flakes processing line,cereal corn flakes production line,oats corn flakes machine,corn flakes breakfast cereals making machines,corn flakes production plant, corn flakes breakfast cereals production line,cereals/corn flakes processing line,corn flakes line,corn flake extrude processing line,please contact mr.peter, welcome you visit us!

saixin machinery are professional corn flakes machinery manufacturer, and professional food extruder machinery leader.

Contact Us

- Jinan Saixin Machinery Co., Ltd.

Product Categories

New Products

-

Soybean protein /High-moisture soya protein food making machine

-

Corn flakes/Breakfast cereals processing line

-

Extrusion baked puffed snacks processing line

-

Large-size animal feed processing line

-

Soybean protein /High-moisture soya protein food processing line

-

Extrusion puffed food machine

-

snack food machine snacks twin screw extruder puff corn machinery

-

Corn Puff Snacks processing plant Extruder Machine

-

corn snack puffed making machine from saixin of China

-

jinan snack extrusion food extruder machine

-

core filling machine

-

kurkures making machine /cheetos making machine since 1988

-

snacks Processing Line by chinese supplier since 1995

-

snack making machine,inflated/puffed food extruder by chinese supplier since 1995

-

puffed food processing line , snack machine by chinese supplier since 1995

-

snack machine , corn puff machine , rice puff machine by chinese supplier since 1995

-

panko bread crumb making machine puff snack production line jinan price

-

Oil drilling grade starch making machine

-

Web,Compound inflating food,Grain fried pellets prrocessing Line

-

fried snack machine/fry pellet machine

-

CE Certificate chips and corn snacks production line

-

food extruder, double screw extruder, corn chips machine

-

saixin corn puffed snack making machine, processing line with CE certificate hot sale in 2019

-

corn puffed machine with CE certificate, from saixin company made in china

Popular Searches

- electric grinder

- Separating Machine

- Color Sorter

- Color Sorter Machine

- kitchen equipment

- Color Sorting Machine

- Food Dehydrator

- Nut Sorting Grading Machine

- automatic drying oven

- belt color sorter

- Nut Color Sorter

- vegetable slicer

- dicer

- Sorter Machine

- Sorting Machine

- beater

- Food Cutters & Slicers

- Vegetable Cutter Slicer

- Meat Slicer

- Meat Slicing Machine Slicer

- Vegetable Cutter

- Fruit Sorting Machine

- Bean Sorting Machine

- dehydrator

- Electric Grinders

- meat mincer

- Electric Meat Grinder

- meat grinder

- Fish Food Processing Machine

- Fresh Machine

Recommended Products

- Smart Fish Grilling Oven - Restaurant Grade, Saves Energy & Labor Costs

- 200–300 kg/h Feed Pellet Machine for Small-Scale Production

- Automatic Steam/Electric/Gas Jacketed Cooking Kettle/Cooking Pot with Mixer/Agitator for Sauce Curry Paste

- Build a Smarter Aquafeed Plant with Kawise Extruder Feed Machine

- 1T/H Feed Pellet Production Solution from Kawise Machinery

- Pellet Die Size & Machine Selection Guide

- Maximize Feed Efficiency with Kawise Small Feed Pellet Machine

- Efficient 200-300kg/h Feed Pellet Line for Your Business

- High-Efficiency 300-400KG/H Feed Pellet Machine

- Feed Pellet Machine: The Perfect Solution for Livestock and Poultry Feed Production

- Commercial | Industrial Peanut Butter Machine

- Automatic Coffee bean color sorting machine Bean color sorter

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machinery for Food, Beverage & Cereal > Pet Food Processing Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile