Home > Products > Freeze dryer > LG50 fruit vacuum freeze drying machine for freeze dried pomegranate/Lyophilisate machine/freeze dried fruit processing machine

LG50 fruit vacuum freeze drying machine for freeze dried pomegranate/Lyophilisate machine/freeze dried fruit processing machine

- 300 Set / Sets per Month

- Dalian port

- T/T Credit Card

You May Like

-

food freeze dryers sale / lyophilizer freeze dryer / freeze dried pomegranate fruit making machine

-

Lab scale efficient freeze drying machine for durian and other fruit chips

-

Xinyang fruit vacuum freeze drying equipment for freeze dried durian chips

-

High capacity industrial freeze dryer for durian chips

-

20kg capacity of laboratory lab scale freeze dryer for freeze dried papaya mango durian fruit

-

High Quality Vacuum Food Freeze Drying Equipment

Product Details

| Brand Name | Xinyang | Place of Origin | Liaoning, China | |

| Model Number | LG50 | |||

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Working Princple of Freeze Drying Machine

Under vacuum condition, material is freeze dried via principle of sublimation. The moisture in the pre-frozen material is directly sublimed from solid state (ice) to gaseous state (vapor), without melting. Freeze dried products are formed as sponginess, no shrinkage, rehydration excellent, very little water containing. The freeze dried product in sealed packaging can be stored and transported at room temperature for a long time.

How to process the freeze dried food?

Procedure of freeze dried pomegranate

Freezing: The pomegranate is frozen. This provides a necessary condition for low temperature drying.

Vacuum: After freezing, the pomegranate is placed under vacuum. This enables the frozen solvent in the pomegranate to vaporize without passing through the liquid phase, a process known as sublimation.

Heat: Heat is applied to the frozen pomegranate to accelerate sublimation.

Condensation: Low pomegranate -temperature condenser plates remove the vaporized solvent from the vacuum chamber by converting it back to a solid. This completes the seperation process.

Working principle of freeze dryer with double alternate cold traps

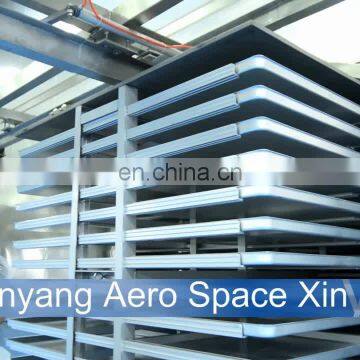

The green color trays with product locate between heating plates in red color, The cold trap I and cold trap II locate under the heating plates inside the drying chamber. Look at the picture as bellow, Cold trap II is working for condensation of vapor that comes from the product to keep good vacuum pressure for freeze drying processing, and Cold trap I is working for defrost, Low temperature steam (15~25℃)comes from De-icing tank into cold trap I to defrost the ice on the tube, and defrost water goes back to de-icing tank and drain out. Condensation and defrost function changes alternately by PLC automation control.

So, This kind construction has limitless on product input capacity, It has much more advantage than other kind of freeze dryers.

| Specification Model | LG30 | LG50 | LG75 | LG100 | LG125 | LG200 | |

| Heating Areas(m2) | 30 | 50 | 75 | 100 | 125 | 200 | |

| Numbers of Vapor trap | Single | Double | Double | Double | Double | Double | Double |

| Trapping Capacity | >400kg/batch | >66kg/hr | >110kg/hr | >165kg/hr | >220kg/hr | >275kg/hr | >440kg/hr |

| Heating Medium | Water&electric | Water&Steam | Water&Steam | Water&Steam | Water&Steam | Water&Steam | Water&Steam |

| Heating Mode | Double side radiation | ||||||

| Temperature range of Heating plates | <95℃ | Normal Temp.~+130℃ | |||||

| Vacuum Pressure (Pa) | 20~133 | ||||||

| Need Refrigeration Capacity (t0=-40℃,tk=-35℃) (Kw) | 55 | 80 | 120 | 160 | 200 | 320 | |

| Consumption of Steam (kg/h) | None | 150 | 200 | 280 | 340 | 400 | 690 |

| Electric Power Supply (Kw) | 75 | 40 | 43 | 63 | 69 | 85 | 115 |

| Tray Numbers | 78 | 80 | 120 | 180 | 240 | 300 | 480 |

| Loading Raw Material | >390 | >400 | >600 | >900 | >1200 | >1500 | >2400 |

Here to see small yield equipments!

1. We guarantee that the commodity hereof is made of the best materials and new brand with top workmanship, and in accordance with quality specification stipulated in product Contract and Appendix.

2. Guarantee period shall be within 12 months from the date of acceptance. During this period, if there are quality problems, we will provide solution by verbal or written communication. If the problem is unsolved, our engineers will repair for you on site as soon as possible. The maintenance is free when there are non-operation errors; otherwise it is for the buyer’s account.

Training plan: We will provide training for those who operate and maintain the freeze-drying machines. Trained by supplier of the equipment in the process of installation and debugging, people can operate and solve the basic mechnical problems independently. In addition, the persons who work in general engineering such as refrigeration, boiler, and transformer substation shall be undertaken by skilled workers.

Shenyang Aerospace Xinyang Quick freezing Equip. Manuf. Co., Ltd was founded in 1985, a leading enterprise incorporating the research, manufacturing, sales and services of food processing equipment and freezing technology. Freeze drying equipment and IQF freezing equipment are widely used around the world.

Xinyang Company closely cooperated with Atlas Company in Denmark, Harbin Commerce University, Zhejiang University and Northeastern University, etc., supporting over 1,000 food engineering projects both domestically and abroad.

It is one of the earliest, largest and most influential professional manufacturers in China. Our products have been exported to USA, Canada, Germany, Netherland, Singapore, Thailand, Malaysia, Indonesia, Korea, Myanmar, Chile, Nigeria etc. The company pays highly attention to food quick freezing, vacuum freeze drying, vacuum frying solution and pre-processing system.

Now Xinyang Company aims to give all of our customers best products and services.

Contact Us

- Shenyang Yangxin Quick Freezing Equip. Manuf. Co,. Ltd.

Product Categories

| Accessory equipment | Cold Storage | Freeze dryer | IQF machine |

| Quicking Freezing Room | Refrigeration system | Ungrouped | Vacuum Fryer |

New Products

-

CE Certificated Industrial Fruit Vacuum Freeze Dryer

-

Hot sale mini freeze dryer for sale laboratory lyophilizer LG0.2 with 3kg loading capacity

-

Lyophilized food machine vacuum freeze dryer for fruit vegetable meat seafood or pet food

-

Mini size pilot vacuum freeze drying machine laboratory for researching and testing for freeze dried food lyophilization

-

Laboratory lyophilizer for freeze dried vegetable miini size pilot freeze drying equipment

-

Lab vacuum freeze dryer pilot lyophilizer for freeze dried food experiment with vacuum pump and cold trap

-

China lab scale pilot vacuum freeze drying machine for freeze dried food processing craft research

-

CE certificate vacuum food freeze dryer applications for industrial lyophilization process

-

Fresh fruit vacuum lyophilisation machine LG200 with PLC and PID control system

-

Vacuum food freeze dehydrating equipment price for freeze dried food

-

Small size laboratory lyophilizer vegetable and fruit pilot vacuum freeze dryr from China manufacturer

-

Lyophilized meat processing machine vacuum freeze dryer lyophilizer for meat seafood or pet food

-

Freeze dried meat processing machine for meat ball or pet training food

-

1500kg capacity food freeze drying equipment with two condensers backwards

-

China xinyang LG75 fruit freeze drying machine for fruit chips healthy crispy snacks

-

Industrial lyophilization equipment of lyophilizer LG200

-

Freeze drying equipment prices for meat, freeze dry meat machine for freeze dried food

-

Scorpion Venom Vacuum Commercial Freeze Dryer

-

CE Certification Large Capacity Freeze Dryer Lyophilizer

-

Industrial Vacuum Lyophilized Honey Powder Machine

-

High Effective Industrial Fruit Freeze Dryer

-

CE Certificate Vacuum Freeze Dryer For Food

-

CE Certificate Vacuum Freeze-Drying Machine For Food

-

Different loading capacity1200KG -- 2400KG banana durian freeze drying equipment prices

Popular Searches

- electric grinder

- Separating Machine

- Color Sorter

- Color Sorter Machine

- kitchen equipment

- Color Sorting Machine

- Food Dehydrator

- Nut Sorting Grading Machine

- automatic drying oven

- belt color sorter

- Nut Color Sorter

- vegetable slicer

- dicer

- Sorter Machine

- Sorting Machine

- beater

- Food Cutters & Slicers

- Vegetable Cutter Slicer

- Meat Slicer

- Meat Slicing Machine Slicer

- Vegetable Cutter

- Fruit Sorting Machine

- Bean Sorting Machine

- dehydrator

- Electric Grinders

- meat mincer

- Electric Meat Grinder

- meat grinder

- Fish Food Processing Machine

- Fresh Machine

Recommended Products

- Smart Fish Grilling Oven - Restaurant Grade, Saves Energy & Labor Costs

- 200–300 kg/h Feed Pellet Machine for Small-Scale Production

- Automatic Steam/Electric/Gas Jacketed Cooking Kettle/Cooking Pot with Mixer/Agitator for Sauce Curry Paste

- Build a Smarter Aquafeed Plant with Kawise Extruder Feed Machine

- 1T/H Feed Pellet Production Solution from Kawise Machinery

- Pellet Die Size & Machine Selection Guide

- Maximize Feed Efficiency with Kawise Small Feed Pellet Machine

- Efficient 200-300kg/h Feed Pellet Line for Your Business

- High-Efficiency 300-400KG/H Feed Pellet Machine

- Feed Pellet Machine: The Perfect Solution for Livestock and Poultry Feed Production

- Commercial | Industrial Peanut Butter Machine

- Automatic Coffee bean color sorting machine Bean color sorter

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machinery for Food, Beverage & Cereal > Pet Food Processing Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile