coal dryer of posco

- 1

- T/T L/C D/P D/A Credit Card PayPal Other Cash Escrow

- 1 days

You May Like

Product Details

| Brand Name | 1 | Place of Origin | Azerbaijan | |

| Model Number | 1 | Type | Vertical | |

| Certification | 1 | After-sales Service Provided | Engineers available to service machinery overseas | |

| Warranty | 1 | Weight | 1 | |

| Dimension(L*W*H) | 1 | Voltage | 1 | |

| Condition | New | Power(W) | 1 | |

| CNC or Not | CNC |

Product Description

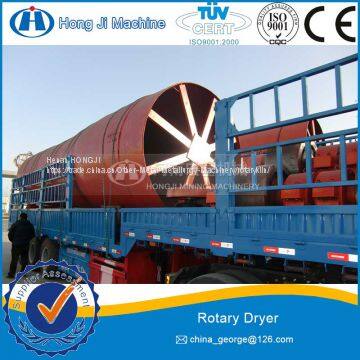

Introductions of biomass rotary dryer price

In line with our many years’ profound experience and clients’ positive feedback, we design and develop the most environmental and energy-saving cocurrent drum dryer with section-by-section heating function.

Cocurrent drum dryer, specially designed for raw materials used for making biomass energy pellets, is adopted with section-by-section heating technique, thus being much more energy-saving than traditional type, and maximizing in energy conservation and drying cost. The suitable materials are like sawdust, wood chips, shavings, rice husk, vinasse waste, etc.

For the traditional cocurrent drum dryer, combustion chamber and wet material feeding are in the same side, so do hot air and material movement. Wet materials move to discharging end from feeding end, likewise, hot air is vented from feeding end to discharging end under the action of fan blower and IDF, where wet materials are dried along with air heating. In the initial stage of cocurrent drying, the driving force is more powerful, the drying medium’s temperature will lower along with the temperature increment of wet raw materials, therefore, and this kind of dryer only fits for materials with lower drying requirements and smaller capacity.

To raise the capacity of dryer, it can be done thru increasing dryer’s diameter and length, and elevating hot air temperature; but over temperature will be more likely to ignite raw materials, so the left ways are to increase dryer’s diameter and length; the temperature of drying materials in the back of dryer will be too low along with the raised length of dryer, thus limiting drying effect and capacity.

Two critical problems to solve:

(A) . Improve drying efficiency of cocurrent drum dryer

(B) . Lifting the capacity of cocurrent drum dryer

The key to these two problems lies in temperature reduction of materials in the back of dryer, limiting drying effect and capacity.

Cocurrent drum dryer of section-by-section heating solves these two problems by heating section by section process.

Cocurrent drum dryer of section-by-section heating is equipped with an air duct on the basis of traditional countercurrent dryer, which delivers a part of hot air from hot air furnace to the middle of dryer thru fan blower, thus raw materials are dried twice, moreover, further maximizing drying effect and capacity.

The traditional concurrent dryer only has one hot air duct connector, which is in the middle of dryer’s feeding cover.

For cocurrent drum dryer of section-by-section heating, the main hot air duct connector is under the feeding cover, and reheating air duct connector is installed in the middle of dryer’s feeding cover.

Reheating air duct, fixed in the dryer body thru air duct frame, rotates with dryer, and is connected with reheating air duct connector by sealing rotary joint, thus guaranteeing the leakproofness of dryer tunnel. The reheating air quantity is controlled approx. 1/3 of main hot air quantity. Suppose the diameter and length of the dryer are same, Cocurrent drum dryer of section-by-section heating will be able to improve the efficiency and capacity by 20% at least compared with traditional cocurrent drum dryer.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Contact Us

- Henan HONGJI

- Contact namechina_george@126.com Chat Now

- Addressxingyang, Zhengzhou, Henan

Product Categories

| rotary kiln | crusher | mill | rotary dryer |

| case |

New Products

-

carbon fiber rotary dryer sourh africa

-

rotary dryer for coal

-

sand drying equipment for sale

-

where to buy silica sand

-

dried sand

-

rotary drying machine

-

rotary dryer

-

iq oq dq for rotary vacuum dryer

-

Silica and quartz sand rotary dryers for drying sand with direct factory price hot in America and Australia

-

silica sand rotary drum dryer / drying machine/tu

-

Widely used high drying rate silica sand rotary drier

-

Silica Sand Dryer with ISO,CE Quality Approved

-

High efficiency of Steam Tube Rotary Dryer For Sale

-

Hot selling mineral powder rotary dryer with CE & ISO

-

Hot selling mineral powder rotary dryer with CE & ISO

-

Vinasse Rotary Dryer/ Cassava Rotary Dryer/ Coal Slag Dryer

-

China national patent certification industrial rotary dryer/sand dryer/used rotary sand dryer

-

Slag Rotary Dryer Widely Used For Building Materials, Metallurgy, Chemical and So On

-

China factory supply save energy rotary dryer / biomass dryer / biomass rotary dryer

-

15-18t/h China High Efficient Dry-Mixed Mortar Sand Rotary Dryer from DingLi Factory

-

China national patent certification rotary dryer / vinasse dryer / rotary drum dryer

-

High Effective Wood Chips Drum Rotary Dryer

-

11t/h Export Bamboo Chips Drum Rotary Dryer from Professional China Manufacturer

-

protect environment and water dust collector lignite coal rotary dryer

Popular Searches

- drying equipment

- ball mill

- tunnel kiln

- cement plant

- cement machinery

- drying machine

- mining equipment

- mining machinery

- cement production line

- cement equipment

- rotary dryer

- drum dryer

- quick lime

- lime kiln

- lime rotary kiln

- cement kiln

- clinker grinding plant

- cement rotary kiln

- clinker rotary kiln

- limestone rotary kiln

- incinerator rotary kiln

- chemical rotary kiln

- bauxite rotary kiln

- rotary drum kiln

- carbon rotary kiln

- kaolin rotary kiln

- vertical shaft impact crusher

- jaw crusher

- hammer mill

- mining machine

Recommended Products

- chinese milling machine|universal milling machine

- Siemens 808D Small CNC Lathe

- High-efficiency VMC1160 Vertical Machining Centre High-precision Mold Engraving Special CNC Milling Machine

- Milling Cnc Vertical Machining Center VMC850 Cnc Milling Machine

- Electrode processing machine Four-axis CNC precision engraving machine S-500V

- Dust-free high-speed graphite machine Four-axis CNC precision engraving machine S-500V

- Five-axis vertical milling machining center Isostatic isotropic graphite lathe S-2500G

- Graphite round rod outer circle processing equipment Graphite boat cnc S-750NCM

- Graphite engraving machine Battery graphite electrode processing equipment S-500NCM

- Wear-resistant graphite box processing equipment Graphite boat cnc S-750NCM

- Customized graphite CNC machine tool Customized graphite CNC machine tool S-1200G

- Automatic lathe turning graphite Wear-resistant graphite box processing equipment S-500NCM

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machine Tools > Milling Machine

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

china_george@126.com

Hi there! Welcome to my shop. Let me know if you have any questions.

china_george@126.com

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile