Home > Products > 1.Tungsten carbide > Tungsten Carbide Nozzle Guide For Nittoku Winding Machine

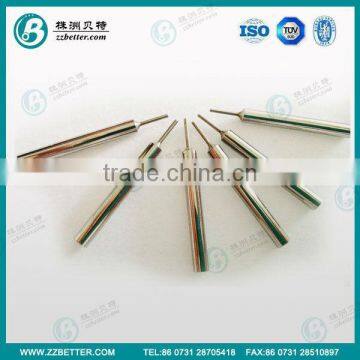

Tungsten Carbide Nozzle Guide For Nittoku Winding Machine

- any port in china

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Place of Origin | Henan, China | Brand Name | zzbetter | |

| Model Number | For Nittoku Winding Machine | Type | Power Tool Parts |

Product Description

Specifications

1.Material:Tungsten Carbide2.Application:Nittoku winding machine

3.wire guide tubes

4.wire guide needles

5.ISO9001-2008

Tungsten Carbide Nozzle Guide For Nittoku Winding Machine

1. Technical parameters

Material: | Tungsten Carbide |

Application: | CNC automatic winding machine |

Polish: | Precision grinding |

Anti-bending: | 2300N/mm |

Hardness: | Reached over HR90 degree |

Roughness of R place: | Ra0.025 |

Roughness of bore: | Ra0.1 |

Work Limit: | d1>0.2mm D1>0.7mm |

Function: | Protect enameled-wire |

2.Detailed Product Description:

Tungsten carbide nozzle also call wire guide tubes or wire guide needles.

Tungsten Carbide Nozzle is made by the precision machining with the tungsten carbide materials (super hard alloy). The hardness reached over HRA90 degree while the anti-bending degree reached over 2300N/mm. We do the precision grinding and surface treatment to achieve Ra0.1 of the bore roughness and the Ra0.025 of the R place of both ends. There is a scientific curvature radius design in the both entrance. This design can ensure a smooth transit of the thread. Due to the overall materials processing, and no elevation in the bore, the phenomenon of easy-bending and plugging has been improved comparing with the ruby nozzle.

3.Product Features:

1. High Wear Resistance This is assured by the choice of materials for wear elements possessing a minimum hardness in excess of Vickers 1, 000 (HRC 70).

2. Scratch-Proofing Eliminate wire insulation film damage, low friction resistance, stable wire tension. The wire-guiding surfaces are mirror finished by diamond lapping to a surface roughness of 2 -4 micro inches Ra or better, material permit.

3. Straightness and Stiffness Straightness and Stiffness are defined by the wire exit being concentric and inflexible with respect to the nozzle locating. In plain terms, the wir

e should exit from the nozzle concentric to the locating? To within 0.02 mm, with or without load. A geometric characteristic presentation is shown at upper left. Concentricity to within 0.01mm.

4. Precise Exit Radii Because the coil winding nozzle's Exit Radii governs the angle of the wire exit from one coil to the next, it should be monitored to + / - 0.025 mm. This is done by digital measurement, shown at upper right.

4.Sketch

5.Size

6.Application

Applied for wire coil winding of various motors

Work Limit: d1=d2>0.10mm

D1>0.30mm

Contact Us

- Zhuzhou Better Tungsten Carbide Co., Limited

- Contact nameYan Luo Chat Now

- Phone86-731-28705418

- AddressHuanghe North Road, Zhuzhou, Hunan

Product Categories

New Products

-

Full size of tungsten carbide sealing ring

-

Cemented Carbide Sealing Ring

-

Rolled Rings, Bearing Rings

-

High Quality Rolled Ring Forging

-

Best Price cemented carbide thread roll ring

-

Rolling Ring for Rotary Kiln

-

Customerized Cemented Carbide Rings for Rolling Mill

-

High Precision Cemented Carbide Rings for Rolling Mill

-

High Precision Carbide Ring of Rolling Forging

-

Durable Carbide Rollers for Ring Rolling machine

-

High Precision Rolled Rings at Best Price

-

High wear resistance roll rings for face milling machine

-

Customized precision roll rings for metallurgy machinery

-

tungsten carbide wear rings

-

Tungsten Carbide Roll Rings for Sale

-

Cemented Carbide Roll Mill

-

Cemented Carbide Rolls for Rolling Mill

-

Customerized Cemented Carbide Grooved Rollers

-

Tungsten Carbide Sealing ring finished

-

Tungsten Carbide Sealing rings blanks

-

high abrasion resistance and corrosion resistance Tungsten Carbide Sealing rings

-

YG6X tungsten carbide sealing ring of mechanical sleeve and seal

-

Tungsten carbide sealing rings with complicated shape

-

carbide mechanical seal ring

Popular Searches

- Carbon Brush

- Diamond Segment

- circle cutter

- Power Tool Accessory

- hcs

- Power Tool Spare Part

- angle grinder armature

- angle grinder carbon brush

- Copper Carbon Brush

- Silver Carbon Brush

- Power Tool Carbon Brush

- Replacement Carbon Brush

- chain saw oil pump

- segment

- diamond cutter

- gang saw segment

- makita power tools

- dewalt power tools

- oscillating tool

- oscillating saw blades

- Multi Tool Blade

- carbon brushes

- copper carbon brushes

- Block Cutting Segment

- Power Tool Part

- Carbon Brush Set

- Carbon Brush Replacement

- dewalt tools

- Drill Press Stand

- bosch power tools

Recommended Products

- KNE IKO high-precision modular cross roller linear guide CRWG4-280H SP

- KNE IKO high-precision modular cross roller linear guide CRWG4-280H

- KNE IKO high-precision modular cross roller linear guide CRWG3-200H

- KNE IKO high-precision modular cross roller linear guide CRWG3-150

- KNE IKO high-precision modular cross roller linear guide CRWG3-125HSP

- KNE IKO high-precision micro guide rail LWL (F) series self-lubricating guide rail LWLC...3

- KNE IKO high-precision micro guide rail LWL (F) series self-lubricating guide rail LWL3

- KNE IKO high-precision micro guide rail LWL (F) series self-lubricating guide rail LWL2

- KNE IKO high-precision micro guide rail LWL (F) series self-lubricating guide rail LWL1

- KNE IKO high-precision micro guide rail LWL (F) series self-lubricating guide rail LWL1...Y

- KNE IKO high-precision modular cross roller linear guide CRWG2-30

- KNE IKO high-precision modular cross roller linear guide CRWG1-20

Find Similar Products By Category

- Industrial Equipment & Components > Universal Hardware Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Yan Luo

Hi there! Welcome to my shop. Let me know if you have any questions.

Yan Luo

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile