Home > Products > AAC block plant > Autoclaved aerated concrete block price/ AAC plant/ aac block for sale

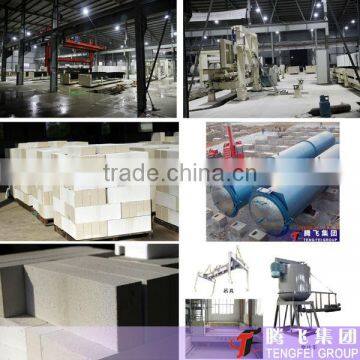

Autoclaved aerated concrete block price/ AAC plant/ aac block for sale

- Qingdao/Tianjin/Shanghai

- T/T Credit Card

You May Like

-

autoclaved aerated concrete aac production line

-

AAC making machine/aac block machine 50000-300000 m3/year -2014 Big sale

-

Professional production-aac autoclaved aerated concrete block

-

aac block machine/aac block plant manufacture

-

AAC concrete block plant /AAC brick production line/AAC block for sale

-

aac block/ AAC block production line/AAC block manufacture

Product Details

| Condition | New | Type | Other, Autoclaved aerated concrete block price | |

| Brick Raw Material | Other, cement,sand/fly ash,gypsum,lime and so on | Processing | Brick Production Line | |

| Method | Autoclaved Aerated Concrete | Automatic | Yes | |

| Capacity | 50,000-450,000m3 /year | Place of Origin | Henan, China | |

| Brand Name | Teng Fei | Model Number | 150,000m3/year AAC block plant | |

| Voltage | 220V/380V | Power | 630kw | |

| Dimension(L*W*H) | as shown in table | Certification | ISO9001:2008& BV | |

| Warranty | 24 months | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

Autoclaved aerated concrete block price1.Power:630kw

2.FOB price get latest

3.light weight,environment friendly

Autoclaved aerated concrete block price/ AAC plant/ aac block for sale

1. Advantage of Autoclaved aerated concrete block price

1.Light-weight :

The AAC block weight usually is 500-700kg/m3. It apply to fill walls of high-rise building and the main wall of low-rise buildings to make the whole building self-weight than normal weight reduce above 40% of composite

masonry structure building . And that improves much building anti-aseismic ability.

2.Good heat preservation:

The AAC block coefficient of thermal conductivity is commonly 0.11 0.18 kcal/m 0 hour.

The heat preservation effect of 20 cm aerated concrete wall is equivalent to 49 cm thick clay brick wall thermal

insulation effect. Obviously the heat insulation performance is significantly superior to 24 cm brick wall.

Thus,it greatly thin the thickness of wall body. Correspondingly it will expand the effective use of the building

area, save construction materials thickness, improve the construction efficiency, reduce the engineering cost and

weight of the building.

3.High strength:

By experiment, aerated concrete block compressive strength is greater than 25 kg/cm2, equivalent to 125 clay

brick and lime-sand brick compressive strength .

4.Nice anti-seismic performance:

The aerate concrete block is light-weight,good overall performance,small inertia force during the earthquake .

5.High temperature resistance:

When temperature is below 600, the aerated concrete block compressive strength increased slightly, when the

temperature is controlled in 600, its compressive strength is close to room temperature compressive strength, so

the aerated concrete as building material fireproof performance meet national fire protection standards.

2. Autoclaved aerated concrete block price ,aac line,aac plant,AAC brick plant

1) Product weight is according to 600kg/m3 to control.

2) Annual capacity 50,000m3-450,000m3

3) Water and material rate 0.631

4) O One mould product 2.88M3

5) Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

6) Casting slurry temperature 38-42 degree

7) Body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

8) Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6

hours/1.6Mpa, total 6.5 hours.

3. Cement lime Sand style aac autoclaved aerated concrete block raw material proportion

Name | Unit | Cement Lime Sand |

Sand | % | 55-65 |

Cement | % | 10-20 |

Lime | % | 20-30 |

Gypsum | % | 2-3 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.65-0.75 |

Casting system | OC | 35-38 |

Aluminum mixing time | S | 30-40 |

Cement lime fly ash style aac autoclaved aerated concrete block

name | unit | Cement lime fly ash |

flyash | % | 65-70 |

cement | % | 6-15 |

lime | % | 18-25 |

gypsum | % | 3-5 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.60-0.65 |

Casting system | OC | 36-40 |

Aluminum mixing time | S | 30-40 |

1.Delivery time: 15 days after receipt of your deposit.

2.Payment terms: 30% T/T in advance, the balance is paid (by T/T) before delivery.

3.Package:

1).Wire cables are used for fastening the machine on the trailer or inside the container.

2).Cork wood are placed in front or behind the machine to protect it.

3).Plastic film is covered on the machine as a rain-roof.

4).Crane is used during the whole loading.

Why chose Henan Teng Fei?

1.Teng Fei give priority to with construction company, during years of construction equipment, progress in practice and has strong practicability.

2.Our company has years of experience in project negotiation and can provide customers with effective business negotiations guidance to win project

3.in addition to providing equipment and technical training, we also provide free foam concrete project system solutions to help you get maximum benefit.

What services does it provide?

1.pre-sale service: our company can provide technological guidance and formulate suitable equipment matching program according with your specific production requirements.

2.on-purchase service: our company can solve professional technical problems and other related issues for you.

3.after-sales service: our company provides that engineers available to service machinery overseas and equipment for life maintenance.

What is the Teng Fei’s basic philosophy?

Henan Teng Fei Machine Manufacturing Co., Ltd. is a collection of scientific research, development, production marketing for the integration of manufacturing enterprise; The company execute principles “development is a competition philosophy” and take “efficient, pragmatic, cooperation, innovation “as beliefs.

Contact Us

- Henan Teng Fei Machine Manufacturing Co., Ltd.

- Contact nameSunny Qin Chat Now

- Phone0086-371-67103656

- AddressXintian Street, Xushui Town, Zhongyuan District, Zhengzhou, Henan

Product Categories

New Products

-

AAC,AAC Block, AAC block production line

-

2013 AAC block /aac brick plant

-

Sand/Fly ash aac, AAC block plant manufacture

-

Ground turn over craft- aac concrete block machine 50,000-150,000 CBM/year aac bricks

-

High quality AAC ,AAC block plant manufacture

-

Aerated autoclave conrete/ AAC block machine

-

NEW aac blocks price 150,000m3 aac wall panel -Air roll-over craft

-

Fly ash/Sand AAC block production line

-

AAC,AAC Block, AAC block production line

-

Fly ash/Sand AAC block production line

-

AAC block producing line

-

50,000-450,000m3 /year aac autoclaved aerated concrete block

Popular Searches

- Sand Making Machine

- Sand Making Production Line

- building model making

- Asphalt Mixers

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- Asphalt Concrete Mixer

- Mobile Asphalt Mixer

- Asphalt Bitumen Mixer

- Asphalt Mixer Plant

- vehicle equipment

- paver

- Making Machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- Asphalt Drum Plant Bitumen

- double drum

- Brick Making Machinery

Recommended Products

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Cheap Brick Machine– Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- Smart Brick Maker– PLC Control System | Energy-Saving | Ideal for Construction Business

- Industrial Brick Machine– Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- "Industrial Block Making Machine – Exported to 30+ Countries, OEM Available!"

- "Industrial Block Making Machine – Exported to 30+ Countries, OEM Available!"

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sunny Qin

Hi there! Welcome to my shop. Let me know if you have any questions.

Sunny Qin

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile