Home > Products > Ore Beneficiation Equipment > Reliable product competitive price super river sand rotary dryer

Reliable product competitive price super river sand rotary dryer

- 50 Set / Sets per Month

- any ports

- T/T

You May Like

-

300t/d copper ore flotation plant from manufacturer

-

Ore Washer Supplier

-

High Efficiency and Low Cost Raymond Mill

-

Competitive Price Stone Washer Supplier

-

Rock Milling Machine for Sale

-

2014 Best quality flotation cell for mining / flotating separator/ flotation plant /flotation equipment/ sf flotation machine

Product Details

| Condition | New | Type | Rotary Drying Equipment | |

| Place of Origin | Henan, China | Brand Name | DH | |

| Model Number | multi-type | Certification | SGS , CE, 3A | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

1. China famous manufactory2. ISO9001 quality

3. Best price in the market

4. Good reputation from users

6. Multi-type dryer

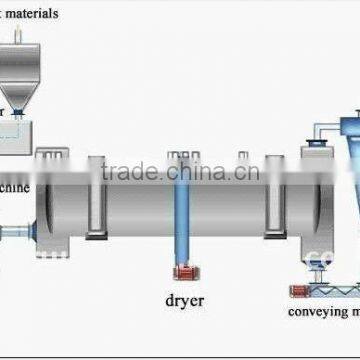

River Sand, Silica Sand Rotary Dryer with Dust Collector Introduction:

The industrial dryer( River Sand, Silica Sand Rotary Dryer with Dust Collector ) is a type of dryer employed to reduce or minimize the liquid moisture content of the material it is handling by bringing it into direct contact with a heated gas. The industrial dryer is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The industrial dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the industrial dryer under gravity.

River Sand, Silica Sand Rotary Dryer with Dust Collector Application:

Industrial dryer( River Sand, Silica Sand Rotary Dryer with Dust Collector ) is mainly used for the drying of materials like slag, clay and coal dust in building material industry or metallurgy industry, and leaching slag in metal beneficiation.

In order to control the temperature of the industrial dryer, a thermocouple which can show the temperature change of the industrial dryer’s feeding and discharging ends is allocated on the feeding and discharging devices. This offers support for the better control of the working temperature (normal 350-380 centigrade) in the drum.

Industrial dryer( River Sand, Silica Sand Rotary Dryer with Dust Collector ) is used in the drying of graininess material, and sticky paste material or high moisture material by adding materials.

Industrial dryer ( River Sand, Silica Sand Rotary Dryer with Dust Collector )advantages: great production capacity, wide rang of application, small flow rate resistance, large fluctuation range in manipulation and convenient operation.

Industrial dryer is most used in the drying of sand, mineral powder, coal slurry, chicken manure and dairy manure.

Industrial Dryer ( River Sand, Silica Sand Rotary Dryer with Dust Collector )Structure:

This industrial dryer consists of rotary body, throwing flitch, transmission device, supporting device and sealing ring.

The industrial dryer of our factory adopts new type throwing flitch device which has multi-functions such as guidance, current sharing and material throwing and can make the materials distributing evenly on the radial section of the industrial dryer. So that the material curtain become thin, even and universal and exposed to the hot current totally thus the heat energy is fully utilized.

The industrial dryer in our factory chooses the right operation parameter, the coal consumption and power consumption is 10-15% lower than general dryer, and the output per hour is 10-15% higher. Industrial dryer is widely used in the cement and beneficiation industries.

Technical Parameters of Professional rotary dryer:

Specific-ations(m) | Capacity(t/h) | Main motor | Main gear box | Weight(t) | ||

Power(kw) | Model | Model | Speed reduction ratio | |||

Ø1.2*10 | 2.5 | 7.5 | Y160M-R3 | ZL50-16-I | ----- | 13.5 |

Ø1.5*12 | 3.3-4.9 | 10 | Y160L-6-B3 | JZQ500-III-2F | ----- | 18.9 |

Ø1.5*15 | 4-6 | 18.5 | Y200L1-6 | JZQ500-III-2F | ----- | 21 |

Ø1.8*12 | 4-6 | 18.5 | Y160L-6 | ZQ50-16II-2 | 16.46 | 22.83 |

Ø2.2*12 | 7-12 | 18.5 | Y200L7-6 | JZQ650-III | 31.5 | 37.6 |

Ø2.2*14 | 7-12 | 22 | Y200L7-6 | JZQ650-III | 31.5 | 40 |

Ø2.2*16 | 12 | 30 | Y225M-6 | JZQ750-III | 31.5 | 45 |

Ø2.4*14 | 12 | 30 | Y250M-6 | JZQ750-III | 31.5 | 51 |

Ø2.4*18 | 10-13 | 37 | Y250M-6 | ZL85-13-I | 27.16 | 54 |

Ø2.4*20 | 10-14 | 37 | Y250N-6 | ZL85-13-I | 27.16 | 54.14 |

Ø3*20 | 25 | 55 | Y250M-4 | ZL100-16-I | 41.52 | 78 |

Ø3*25 | 32-36 | 75 | YR280M-4 | ZL100-16-I | 41.52 | 104.9 |

Contact Us

- Zhengzhou Dahua Mining Machinery Co., Ltd.

- Contact nameHongliang Liu Chat Now

- Phone86-371-67849628

- AddressThe East of Sanshili Industry Zone,Zhengshang Road, Zhengzhou, Henan

Product Categories

New Products

-

Saw-tooth Wave Jigger, Jipping Machine with Long After Sale-service

-

Competitive Price Stone Washer, Ore Washer

-

Globe Mill with ISO9001

-

Spiral Classifier from Manufacturer

-

High Quality 800~1000kg/h biomass pellet machine , sawdust pellet machine

-

2014 Best Selling Ceramic Sand Processing Line for Sale

-

professional mobile pcb recycling equipment

-

new-type PCB waste recycling equipment

-

waste PCB recycling machine

-

2011 Hot!!! new PCB recycling machine

-

new type PCB recycling equipment

-

Circuit board recycling equipments

Popular Searches

- Tube Bundle Dryer

- Fluid Bed Dryer

- Dryer Equipment

- Spray Drying Equipment

- vacuum dryer

- Plate Drying Machine

- industrial dryer

- Rotary Drum Dryer

- Cross Joint Shaft

- rotary dryer

- drum dryer

- Vacuum Drying Equipment

- Rotary Drying Equipment

- Dryer Oven

- Spray Dryer

- Rotary Dryer Machine

- Industrial Rotary Dryer

- Rotary Drying Machine

- hopper dryer

- Hopper Drying Machine

- Freeze Dryer

- Industrial Centrifugal Dryer

- cowpea seed

- blood gas machine

- Drier Machine

- lab spray dryer

- Drier Equipment

- air tunnel

- air drying

- mineral dryer

Recommended Products

- Yosion Technology YH-9423A Drying Oven;Industrial Oven;Trolley Oven

- Peptide white powder spray dryer Stainless steel plant protein spray drying equipment

- Yosion Technology YH-D2000T Drying Oven;Industrial Oven;Trolley Oven

- Yosion Technology YH-9623A Drying Oven;Industrial Oven;Sample Preparation Equipment

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- .[Energy Efficiency Certified] [24KW Motor/90KG Fuel] Vacuum Dryer for Wood Chips/Straw Drying [Jinan Hengyuruntai Supplier]

- Freeze Dryer

- Vacuum freeze dryer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Chemical Drying Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Hongliang Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Hongliang Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile