Home > Products > Spray Drying Granulator > WPG Asepsis Spray Dryer

WPG Asepsis Spray Dryer

- 100 Set / Sets per Month

- shanghai

- T/T Credit Card

You May Like

Product Details

| Condition | New | Product Type | Other, all kinds of materials | |

| Place of Origin | Jiangsu, China | Brand Name | YIBU | |

| Model Number | WPG | Voltage | according to customer needs | |

| Power(W) | 15kw | Dimension(L*W*H) | 1.2*0.6*0.8m | |

| Weight | one ton | Certification | CE:UL:FAD:ISO14001:9001 | |

| After-sales Service Provided | Engineers available to service machinery overseas |

wooden case

Product Description

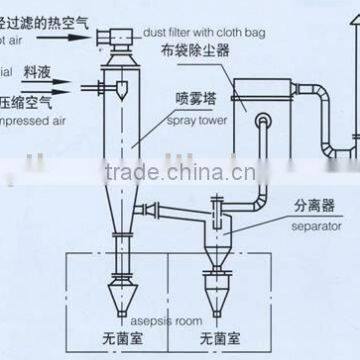

The drying device with asepsis and spray is key equipment for manufacturing power injection in pharmaceutical industry. Many antibiotics, such as streptomycin sulfate, gentamicin sulfate, kanmycin sulfate and so on, need the drying device with asepsis and spray to manufacture during the process of production. In the system of the drying device with asepsis and spray, all raw materials and air entered into the system must sterilize. The collect of product should be carried out in the asepsis chamber. Therefore the spray liquid can be transferred to the sprayer after it is sterilized. The compressed air can be used after purification too. ( The above mentioned two items should be completed by customers.)

The air used for drying should be purified through primary and middle effective filters, blower and high effective filter. Then the purified air is heated through heater and transferred to the dryer. The dried finished products and air are separated through cyclone separator. The finished products should be packaged at the working table in asepsis room. The tail air is discharged through filter.

The device adapts sprayer with two ways of flow. Its features are simple in structure, good in contact of flow, uniform in atomization. The requirement of asepsis spraying can be reached.

There is cleaning system in the tower, it's easy to clean the powder on the inside wall of tower.

Because the hot air passes through the primary and middle and high effective filters, the purified quality of air is high. It is in conformity with the requirements of GMP.

Company Profile

Changzhou Yibu Drying Equipment Co., Ltd. is a leading manufacturer of drying, mixing, granulating and grinding equipment in mainland China. Our company covers an area of more than 50,000 square meters, and has over 180 sets of special processing equipment and powerful technical force. We are a specially-designated enterprise of China Association of Pharmaceutical Equipment and China General Chemical Equipment Corporation. Especially, we are ISO9001 and ISO14001 certified. The founder of our company, Mr. Zha Guocai has devoted himself in the research, manufacture, production and business of drying equipment for over thirty years. Our company pays much attention to science and technology renovation and has cooperated with many institutes located in Shanghai, Wuhan and Chongqing, such as the Ministry of Chemical Industry and Tsinghua University. Therefore we can launch 3 to 5 new varieties into the market every year. In 1998, through approval of state relevant departments, our company set up China Research Center of Drying and Granulating that can research new process, develop new technology and provide new products for pharmaceutical, chemical and foodstuff industries. We also have many testing machines in our lab for clients to make trials. Currently, our products have been sold to nearly 50 countries and regions around the world, including the USA, Mexico, Columbia, Guatemala, Brazil, Peru, Australia, New Zealand, Ghana, Russia, Cyprus, Greece, Iran, Indonesia, Malaysia, Philippines, Korea, Japan, Taiwan, and Hong Kong. If high quality drying, blending, granulating and grinding equipment and professional services and technical support are what you are looking for, please do not hesitate to contact us. You are welcome to come to our factory to make investigation and trials.

Contact Us

- Changzhou Yibu Drying Equipment Co., Ltd.

- Contact nameJenny Wang Chat Now

- Phone0086-519-88910618

- AddressJiaoxi, Changzhou, Jiangsu

Product Categories

New Products

-

JCT Series Oven for Pharmaceutical

-

GM High-temperature sterilizing oven

-

High-temperature sterilizing oven used in chemical

-

Rotating Barrel dryer for drying chicken manure ( drier )

-

Rotating Barrel dryer ( drier )

-

Double cone Vacuum Dryer for sodium hypophosphite

-

Double cone Vacuum Dryer for L-Tryptophan premix

-

Double cone Vacuum Dryer for synthetic drugs

-

New Condition and Dryer Type food lyophilizer

-

Double cone Vacuum Dryer for Zinc Sulfate

-

Double cone Vacuum Dryer for citric acid monohydrate

-

Double cone Vacuum Dryer for sodium tripolyphosphate

Popular Searches

- Fluid Bed Processor

- granulator

- Fertilizer Granular Machine

- Production Line Chemical

- Roller Press Compactor

- fertilizer blending plant

- bio fertilizer machine

- fertilizer machines

- fertilizer equipment

- organic fertilizer production line

- fertilizer production line

- compound fertilizer granulator

- fertilizer granulator machine

- fertilizer granulator

- bio fertilizer plant

- Fertilizer Making Machine

- Fertilizer Granulation Machine

- Fertilizer Granule Making Machine

- Fertilizer Pellet Making Machine

- Fertilizer Granulating Machine

- Compost Turner Machine

- pharmaceutical powder granulator

- Roller Press Granulator

- organic fertilizer granulation machine

- small rotary tablet press

- lab granulator

- fertilizer granule machine

- urea plant

- soft capsule making machine

- pill maker

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Granulator

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jenny Wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Jenny Wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile