Home > Products > JET GROUTING MACHINE > high quality jet grouting borehole equipment

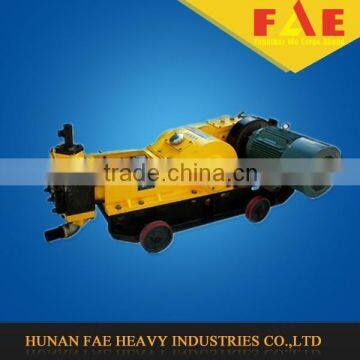

high quality jet grouting borehole equipment

- 50 Unit / Units per Month

- China port/Shanghai/Shenzhen

- T/T Credit Card

You May Like

-

jet grouting, hydraulic type rig, drilling rigs equipment

-

Special hot-sale jet grouting drilling rig equipment with compressed air to cut the soil

-

hydraulic type rig,drilling rigs equipment with pressure 35 Bar jet grouting

-

hydraulic type rig,drilling rigs equipment with Inlet diameter 64mm jet grouting

-

outlet diameter 32mm drilling rigs equipment jet grouting

-

engine power 11KW drilling rigs jet grouting

Product Details

| Place of Origin | Hunan, China | Brand Name | FAE | |

| Model Number | SNS-150 | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

FAE Jet Grouting

What FAE jet grouting could offer?

Jet Grouting or High Pressure Grouting can be employed in all soils

from clays to coarse gravels irrespective of grain size distribution, void

ratio or pore sizes. Jet grouting uses a high pressure jet(approx. 400 bar) to cut the natural soil in order to mix and partially replace it with the

grout. This creates a "soilcrete" body whose strength and/or permeability characteristics are independent of the original soil fabric.

To construct a jet grouted column, a small diameter bore is drilled with

the jet rods and drill bit down to the design depth. Drilling gear and drill fluid are chosen to be appropriate for the soil type. To increase the

diameter of the jet grouted column and to optimize usage of cement and efficiency in dense, cohesive or very compact soils, pre~cutting with

high pressure water may be employed during the initial drilling.

As soon as the design depth has been reached, the rods and drill bit are

slowly withdrawn from the soil. During the withdrawal, grout is injected at high pressure (approx. 400 bar) into the soil from jet nozzles which

are situated horizontally just above the bottom of the drill bit. The speedof particles in the jet is approx. 200m/s. Because the drill rods and drill bit are kept rotating during withdrawal and jetting, a homogenous

cylindrical body is produced consisting of a mix of injected grout and

displaced soil.

Form and size of the jet grout body can be influenced by varying jet

pressure, withdrawal rate and rotation of the jetting gear.

Some of the soil~grout mixture overflows through the drill hole onto theground surface. This spoil is collected and removed.

All materials used in the jet grouting process~water, cement, occasionally bentonite and the soilare natural inert materials which have no

negative impact on groundwater and environment.

Jet grouted columns can be executed as vertical columns or in any

inclination.

| Specifications | |

| Veriable Displacement | 0-150 lit/min |

| Pressure | 35 Bar |

| Inlet Diameter | 64mm |

| Outlet Diameter | 32mm |

| Power | 11KW |

| Weight | 450kg |

Jet Grouting Methods

FAE uses three different methods for jet grouting:

Simplex-Method

Cement grout is injected into the soil with high pressure (approx. 400 bar) at the drill head (monitor). The jet cuts the soil and mixes it thoroughly with the grout. The Simplex~method is appropriate for shallow depths and horizontal jet grouting.

Duplex-Method

Using special rods with double inner conduit (Duplex string) compressedair is introduced into the grout jet at its exit point. This adds energy andenables the Duplex~method to reach much greater depths and achieve

larger diameters than the Simplex-method.

Triplex-Method

The Triplex~method uses a high pressure water jet with compressed air

to cut the soil. Cement grout is introduced into the soil and mixed with itthrough a separate jet nozzle situated just belowthe jet nozzle for the

water (Triplex string with triple inner conduit rods). The Triplex~method isan appropriate method for underpinning, especially in cohesive soils.

Dimensions

Different geometric forms and dimensions of the soilcrete body can be

produced with jet grouting:

1~without rotation of the rods during withdrawal and jetting, cut~off

walls of various thickness can be produced;

2~ with partial rotation, segments of a cylinder can be produced (bow-tie);

3~with full rotation, a cylindrical body is produced; diameter of the

cylinder can be changed by varying withdrawal rate and/or jet pressure.

Jet Grouting Parameters

Jet grouting parameters which are chosen for a given project depend on the required characteristics of the finished product, the geotechnical

characteristics of the soil and the chosen jetting method.

Principle jet grouting parameters are:

~withdrawal rate of the jet string

~ rotation speed of the jet string

~ flow rate of the grout

~ jet pressure

~ jet volume

~ number and diameter of jet nozzles

~ volume and pressure of compressed air

~ mix design of the grout

Applications of Jet Grouting

~ underpinning of existing structures

~ downward extension of foundations in the case of settlements or

increased load

~soil improvement, even underneath existing structures

~ vertical impervious barriers

~ impermeable base for excavations

~ bracing and stiffening of excavations underneath their base

~ connection of sealing walls to existing structures and/or services and

utilities

~ walls for cylindrical or polygonal excavations

~ horizontal screens and canopies for tunneling

~ soil stabilisation between neighbouring excavations or foundation

works

~ impervious connection of individual piles in pile walls

What are FAE jet grouting methods?

What are FAE jet grouting delivery?

Awaiting for your inquiry,we will response you at the first time!

Please contact us from this page or find our contacts from the Index page of our site.

FAE website for your further information:

WWW.FAECHINA.COM

Contact Us

- Hunan Fae Heavy Industries Co., Ltd.

- Contact nameEason wong Chat Now

- Phone86-0731-85718177

- AddressJinzhou New Industries District,Ningxiang,Changsha,Hunan Province,China, Changsha, Hunan

Product Categories

New Products

-

FAE all types of rotary drilling interlocking and friction kelly bar

-

FAE rotary drilling interlocking type kelly bar

-

Bauer type New full interlocking kelly bar for piling rig

-

4 sections key parts of high quality rotary drilling sare parts High Manganese Steel kelly bar

-

Bauer baby drill rig telescoping friction kelly bar

-

4 sections-interlocking kelly bar/ rotary drilling kelly bar for piling rig macthed with IMT

-

Best quality Mait HR180 interlocking kelly bar for drilling rig

-

fae 6-key design and standard modular design of kelly long

-

fae 6-key design and standard modular design of rubber air spring

-

China fae professional manufacturer of cfa long helix drill pipe

-

fae far foundation rig 6 key design and standard modular design of square & hexagonal kelly

-

fae professional helix drill pipe of drillling rig parts

-

fae professional slewing ring bearing

-

engineering machinery piling rig New friction drilling rod kelly bar

-

mechanical locking Kelly bar kelly rod FAE

-

price engineering machinery damping spring for kelly bar

-

lift equipment for kelly bar

-

price engineering machinery drilling telescoping kelly bar

-

FAE popular special and standard modular design of full-interlocking kelly bar

-

Sunward rotary drilling rig friction Kelly bar

-

Mait HR 130/180 piling rig spare parts full interlocking kelly bar

-

Frictional-type pressurizing kelly bar for TESCAR rotary rig

-

Mait Hr130 rotary drilling interlocking kelly bar

-

spec standard rig square friction kelly bar/drilling Hexagonal kelly/kelly pipe

Popular Searches

- concrete truck

- active lime kiln

- lime kiln equipment

- industrial lime kiln

- shaft lime kiln

- vertical lime kiln

- rotary kiln

- cement grinding station

- mixer truck

- Concrete Mixer Truck

- Rotary Kiln Machine

- lime kiln

- kiln

- Lime Rotary Kiln

- Vertical Shaft Lime Kiln

- rotary kiln activated carbon

- cement kiln

- Cement Mixer Truck

- Mixer Tank Truck

- Mixer Machine Truck

- concrete mixer truck weight

- Concrete Mixer Car

- Vertical Shaft Kiln

- Quicklime Production Line

- Quicklime Rotary Kiln

- transit mixer

- mixer vehicle

- Clinker Grinding Plant

- cement truck

- wall paint spray gun

Recommended Products

- Water conservancy engineering mixing rod, concrete vibrator, excavator used

- Construction machinery concrete mixer hydraulic vibrator

- Engineering excavator modified vibrating rod concrete vibrating machine

- Concrete vibrating machine excavator modified vibrating rod

- Vibration compaction machine excavator modification z'd'qi

- Construction of concrete mixer, mechanical sliding mixing bucket

- Slip front mixer forklift modification mixing bucket discount

- Slip front mixer forklift modification mixing bucket discount

- Small shovel to mixer head loader hydraulic mixing bucket manufacturer

- Loader modification, mixing bucket manufacturer, concrete mixing machinery

- Excavator Concrete Vibrator Excavator Hydraulic Vibrator Bunker Vibrating Truck

- Hydraulic vibration compaction Excavator Concrete Vibrator

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Concrete Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Eason wong

Hi there! Welcome to my shop. Let me know if you have any questions.

Eason wong

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile