Home > Products > Brick/block production line > Full-automatic cement brick making machine brick production line QT6-15 fly ash paving brick machines

Full-automatic cement brick making machine brick production line QT6-15 fly ash paving brick machines

- xiamen

- T/T Credit Card

You May Like

-

QT5-15 Automatic Hydraulic Concrete Interlocking Brick Making Machine on sales

-

Vibrated Multifunctional QT6-15 cement concrete sand brick making machine for sales

-

HYM Full automatic QT8-15 hydraulic concrete hollow brick and block making machine

-

Full automatic QT Concrete brick machine production line QT5-15 paving brick forming machine

-

Buy cheap hollow bricks making machine from Huayuan Machinery--- QT6-15 cement concrete brick machines

-

2013 HYM Full automatic brick building machine QT4-15 concrete building bricks making machine south africa

Product Details

| Condition | New | Type | Hollow Block Making Machine | |

| Brick Raw Material | Concrete | Processing | Brick Production Line | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | 20sets per month | Place of Origin | Fujian, China | |

| Brand Name | HYM | Model Number | QT6-15 concrete block making plant | |

| Voltage | 220V/380V | Power | 37.4KW | |

| Dimension(L*W*H) | 9450*3300*2700MM | Certification | ISO | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

ncrete block making plant2.used concrete block making machine

ncrete block making machine

4.power:37.4kw

Full-automatic cement brick making machine brick production line QT6-15 fly ash paving brick machines

1,Main Features

1. Machine frame: adopt high strength steel and special welding technology manufacturing, very strong.

2. Oriented column: made of special steel, chrome plated , and can bear powerful suppress and wears well.

3. Mould head: mechanical and electrical hydraulic synchronous drive, the same height error rarely plate products, good product consistency.

4. Broken arch type cloth device (particularly favorable to porous brick cloth, the more homogeneous)

5. Materails feeder: senser with hydraulic drive technology, using swing car cloth and arch broken bodies, have forced the centrifugal blowdown, cloth quickly, particularly favorable to thin-walled hole more products.

6. Vibrator: hydraulic drive technology, multi-source vibration system, under computer control vertical synchronous vibration generated by the hydraulic pressure drive, frequency adjustable, realize low-frequency charging, the working principle of the high-frequency molding good compaction effect can be obtained for different raw materials, the vibration acceleration of 17.5.

7. Control system: computer control, man-machine interface, USES the Japanese mitsubishi and other brands, the control program integrated practical production experience for many years, combined with the international development trend, design to meet the conditions of writing and become, to achieve without professional, only need a simple training to operation, powerful memory may be a need for the upgrade.

8. Storage and sub-feeder device: by computer control material supply, avoid the material affected by external and internal pressure, to ensure that the material is uniform, products intensity error is rare.

9. multi-purpose of the machine. change the mold to produce various specifications of hollow block, multi-holes brick, paver brick and planting grass brick, slope protection brick, etc.

Production raw materials: the stone powder, sand, gravel, cement, can be a lot of adding fly ash, slag, steel slag, coal gangue, ceramsite, perlite and other industrial waste.

multiple use, it can produce all type of standard building blocks by changing mould.

1,Multi-holes block and hollow block .

2,Cream site heat preservation block.

3,Composite heat preservation concrete block

The above production come with good heat preservation performance, and it meets the new national energy conservation policy.

2.Main technical parameters

| Cycle Time | 15-20(s) | Total Power | 37.4(kw) |

| Vibration Type | hydraulic vibration | Vibration Frequency | 3800-4500(Times/Sub) |

| Machine Dimension | 9450×3300×2700(mm) | Pallet Size | 850×680×20(mm) |

| Vibration Force | 68KN | Gross Weight | 7500(kg) |

| Rated Pressure | 31.5(mpa) | Stacking Machine Power | 2.25(kw) |

3.Brick Sizes and capacity

| Block Specification | Size | Production per Mould(pcs) | Production per Shift(8 hours) |

| Multi-holes Block | 240x115x90mm | 15 (pcs) | 21600-28800(pcs) |

| Standard Block | 240x115x51mm | 30 (pcs) | 43200-57600(pcs) |

| Hollow Block | 390x190x190mm | 6 (pcs) | 8640-11520(pcs) |

| Color Paver Block | 200x100x60mm | 21 (pcs) | 25200-30240(pcs) |

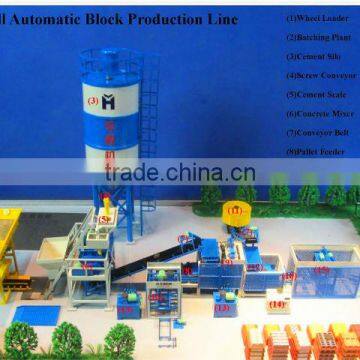

4. Other Accessory Machine QT6-15 cement block making machine

Batching plant

- PL series of concrete batching plant is the front automatic batching equipment of concrete mixing equipment,

- can automatic complete the batching of sand, stone, cement and other material, according to the requirements

- of concrete proportion.This series of products are applicable to different working station.

- Component Part: store hopper, weighing systems, material feeding system, electronic control system,etc

- Structure form: in line or superimposed .

- Feeding way: pneumatic valve and belt conveyor.

- Strength: many kinds of combination forms, high precision weighing, simple operation, high automatic egree,etc

Concrete Mixer

1).The concrete mixer is the advanced, ideal type at home and abroad. Good mixing quality, high automation and efficiency, low energy consumption and noise as well as easy operation are the advantages of it.

2).Besides, it also has the strengths of high speed of discharging, long service life of liner and blades and easy maintenance.

3)Applies for the mix of plastic concrete, dry concrete, light weight aggregate concrete and different mortars.

4).Mtorized discharge port is applied in the machine, which makes it could be matched with dump car.

5).So it is the ideal machine for construction site and prefabrication.

Automatic Stacker

it is used to send the finished brick out automatic which is helpful to imporve the productivity effectively .

5.Other information

2000-4000m2 for the whole production , the bigger, the better

Raw material:8-10% cement, 30-40% sand,50-60% stone power

6.Shipment to the clients

Our clients all over the world

Contact Us

- Fujian Nanan Huayuan Machinery Manufactory

- Contact namejenfy fu Chat Now

- Phone86-0595-26555699

- Addressfengzhou town taoyuan industrial zone 106 NO., Quanzhou, Fujian

Product Categories

New Products

-

Automatic Pallet Loading Machine for block making plant

-

PVC Pallet, for block making machine

-

Low price hot sales QT4-15 block machine for making paver for sale

-

Most popular chinese big full automatic brick making machine qt6-15

-

Energy-saving 24-hour keep working Baking-free Blind Hole eco brava interlock brick making machine

-

High Efficiency HY-JS500 concrete mixer From HuaYuan Manufacturer

-

HY-JS750 concrete mixer cement mixer

-

HY-JS500 concrete mixer used concrete mixers

-

Portable twin shaft electric JS500 concrete mixer for Lower concrete mixer machine price

-

HY-JS500 concrete mixer concrete mixer machine price

-

HY-JS500 Twin Shaft Concrete Mixer portable concrete mixer

-

HYM-JS750 cement mixer in block moulding machine

-

2013 Hot sale in HYM-JS750 concrete mixer used block machine

-

2013 Hot sale in HYM-JS750 concrete mixer quarry stone block cutting machine

-

HYM-JS500 concrete mixer machine price in concrete block machine field

-

HYM-JS500 concrete mixer block manufacture machine

-

HYM-JS500 concrete mixer used granite block cutting machine

-

2013 Hot sale in HYM-JS750 concrete mixer manual concrete block moulding machine

-

HYM-JS500 used concrete mixer for automatic concrete block making machine

-

HYM-JS500 concrete mixer concrete cover block machine

-

HYM-JS500 concrete mixer industrial ice block making machine

-

sawdust block making machine HYM-JS500 concrete mixer

-

manual press brick block machine HYM-JS500 concrete mixer

-

HYM-JS500 concrete mixer Mobile Concrete Mixing Plant

Popular Searches

- Sand Making Machine

- Sand Making Production Line

- building model making

- Asphalt Mixers

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- Asphalt Concrete Mixer

- Mobile Asphalt Mixer

- Asphalt Bitumen Mixer

- Asphalt Mixer Plant

- vehicle equipment

- paver

- Making Machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- Asphalt Drum Plant Bitumen

- double drum

- Brick Making Machinery

Recommended Products

- Industrial Automatic Block Production Line– Daily Output 50,000+ Bricks, Large-Scale Manufacturing

- Brick Conveyor Belt | Heavy-Duty Design for Long Lifespan

- Eco-Friendly Non-Fired Brick Machine Custom Moulds Available

- Automatic Hydraulic Brick Making Machine for Hollow/Solid Blocks | High Output

- Hollow Brick Making Machine – Multi-Mold Options for Load/Non-Load Bearing Blocks

- Paver Block Press Machine – Hydraulic System for High-Strength Pavement & Plaza Bricks

- Hollow Brick Making Machine – Multi-Mold Options for Load/Non-Load Bearing Blocks

- PLC-Controlled Block Molding Machine – Intelligent Operation, Precision Pressing

- Eco-Friendly Non-Fired Brick Press Machine – Energy Saving, Supports Waste Recycling

- Fully Automatic Hydraulic Brick Making Machine

- Automatic Brick Stacking Machine | Robotic Palletizer for Blocks

- Brick Conveyor Belt | Heavy-Duty Design for Long Lifespan

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

jenfy fu

Hi there! Welcome to my shop. Let me know if you have any questions.

jenfy fu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile