Home > Products > emulsify tank > Stainless steel inline homogenize tank for shampoo lotion

Stainless steel inline homogenize tank for shampoo lotion

- shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

-

Stainless steel fixed facial cream vacuum homogenize mixing tank with agitator

-

Bulk discount stainless steel homogenize mixing tank for cream with best quality

-

High quality stainless steel liquid detergent homogenizing mixing tank

-

Horizontal inline homogenize disperse vacuum tank single layer tank system

-

Shampoo detergent liquid product homogenize mixer

-

Liquid hand washing making machine with homogenize mix tank

Product Details

| Condition | New | Mixer Type | Homogenizer | |

| Product Type | Cosmetic | Application | Viscous Fluid | |

| Additional Capabilities | Other, emulsify | Place of Origin | China | |

| Brand Name | sunny | Model Number | JZG | |

| Max. Loading Capacity | 3000L | Voltage | 380V | |

| Power(W) | 0.75KW~45KW | Dimension(L*W*H) | Volume | |

| Certification | ISO9001 | Warranty | 2 Years | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

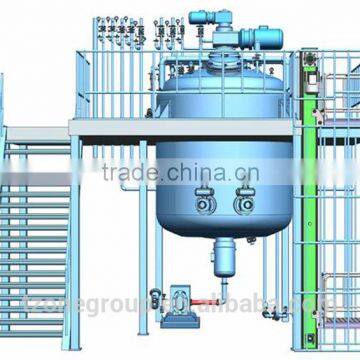

JZG stainless steel homogenize tank for lotion and shampoo

Application:

1.Cosmetic and daily chemical product: Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.

2.Pharmaceutical product: Ointment, Ice packs, injection liquid, penicillin etc

3.Food : Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food etc.

4. Beverage: Fruit Juice, Milk Juice etc.

5.Chemical: Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides ,Shoe polish, general chemicals etc.

Standard structure drawing:

Structure:

This homogenize tank include tank, homogenizer, vacuum pump, water tank, mixer, pipes, meters, valves, temperature control system, heating system, cooling system and control system.

The detail requirement should be according to customer’ requirement

Description:

This stainless steel homogenize tank is used for mixing, dispersing, dissolving, emulsification, dissolution, reaction, formulating, heating, cooling, warm-keeping, cultivating, disinfecting and storage etc. Different types of blades and relevant speed achieve the production condition.

Parameter:

Model | 30L | 50L | 100L | 200L | 500L | 1000L | 2000L | 3000L | 5000L | 10000L | 50000L |

Diameter mm | 300 | 300 | 400 | 500 | 700 | 900 | 1200 | 1300 | 1500 | 1800 | 3100 |

Height mm | 1600 | 1700 | 2000 | 2300 | 2600 | 3000 | 3800 | 4300 | 4500 | 5300 | 8000 |

Filling capacity | 65%-80% | ||||||||||

Inside Pressure Mpa | -0.1---0.2 | ||||||||||

Jacket pressure Mpa | -0.1---0.4 | ||||||||||

Cool method | By jacket | By pipe | |||||||||

Mix speed rpm | 0--300 | ||||||||||

Motor Power kw | 1.1 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 15 | 22 | 50 |

Feature:

1. Suit for the process about formulating, dissolving, heating, cooling, warm-keeping, cultivating, disinfecting and storage. It is available online CIP cleaning ( only suitable for enclosed structure)

2. Designed in accordance with sanitary requirements, so the structural design is very user-friendly, easy to operate, healthy to store.

3. The inner surface is mirror-polished (roughness Ra≤0.4µm); the welding of all kinds of nozzles, endoscopic, manholes and the pot adopt stretch flanging process arc transition, easy to clean with no dead ends, ensure the reliability and stability in the production process.

4.T he main blending adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high.

5.The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging.

Order requirement:

1 How much liter of homogenize tank do you need?

2 what this tank used for?

3 What way do you want to heat the homogenize tank ? By steam or electric?

4 How much speed of the mixer do you need? Do you need Frequency speed?

5 Do you need vacuum system?

6 do you need automatic or manual?

5 When do you need this mixing tank?

Install picture:

Our Services

1 we design the machine according to your raw material viscosity, temperature requirement, vacuum requirement ,heating ways and cooling requirement

2 we manufacture the machine according to the confirmed drawing, and we test the machine then delivery to yourside

3 engineer is available to install the machine and train your operator how to operate the machine

Contact Us

- Zhejiang Sunny Machinery Technology Co., Ltd.

- Contact nameTOM wang Chat Now

- Phone86-577-65021938

- AddressNo. 2 Economic Area, Ruian City, Zhejiang Province. China, Wenzhou, Zhejiang

Product Categories

New Products

-

Standard agitating homogenize disperse liquid mixing tank

-

Single-effect Vacuum Energy Save Milk Water Alcohol Juice Evaporator

-

Stainless Steel Double-effcet Vacuum Milk Water Alcohol Juice Evaporator

-

Vacuum Single-effect Milk Water Alcohol Juice Concentrator/Distiller

-

Automatic Double-effcet Vacuum Milk Water Alcohol Juice Evaporator/Distiller

-

High-efficiency Vacuum Single-effect Milk Water Alcohol Juice Evaporator /Distiller

-

High-efficiency Double-effcet Vacuum Evaporator/Distiller For Milk Water Alcohol Juice

-

Automatic MVR Industrial Evaporator Concentrator Distiller

-

Stainless Steel MVR Milk Water Alcohol Juice Evaporator Manufacturer

-

High Efficiency Stainless Steel MVR Evaporator & ConcentratorFor Milk Water Juice Alcohol

-

SJN2-vacuum evaporator

-

automatic biological bacterial yeast fermentation tank

-

lab biological bacterial yeast fermentation tank

-

automatic biological Vaccine Enzyme ferment tank

-

Stainless Steel Beer Wine Fermenter/Fermentation Tank

-

Industrial Biological Fermentation For Beer Wine

-

Stainless Steel Beer Wine Home Brew/Industrial Fermenter/Fermentation Tank

-

Fermentation tank

-

High-efficiency Tablet Coating Machine

-

Pharmaceutical Laboratory Tablet Coating Machine

-

Automatic Tablet Pill Film coating machine

-

Automatic Pharmaceutical Sugar Coating Machine For Pill Tabelt

-

Automatic Dry Powder Granulator Granulation Machine

-

High Speed Dry Powder Vertical Granulator Granulation Machine

Popular Searches

- mixing tank

- mixing machine

- Lab Mixer

- Liquid Agitator Mixer

- Powder Liquid Mixer

- Blender Mixer

- Drum Mixer

- food mixer

- scrape equipment

- dough mixer

- planetary mixer

- spiral mixer

- Spiral Dough Mixer

- stainless steel tank

- mixing equipment

- powder mixer

- homogenizer

- high speed mixer

- Ribbon Blender

- Powder Blender

- Bin Blender

- button making machine

- vacuum machine

- button press machine

- Soap Making Machine

- Chemical Equipment

- Chemical Agitator

- bubble gum base

- pharmaceutical machine

- Chemical Mixing Equipment

Recommended Products

- Automotive Cabling Harnessing and Connections glue dispensing machine with 2 part epoxy potting compound

- 2k glue potting machine polyurethane dispensing and mixing machine for Fuel Level Sensors

- Power Steering Console two part epoxy pu silicone dispensing and filling glue machine

- Dashboard control borad PCB 2 component epoxy silicone pu dispensing and dosing glue machine CNC automatic

- Electric Vehicle Batteries AB 2k part epoxy resin and hardener metering and mixing pouring filling equipment machine

- Marine Electronics 2k resin mateirals glue potting machine epoxy dispenser PU dosing and mixing machine

- LED Beacons / Navigation / Safety lights potting and encapsulation machine with two parts epoxy potting compound

- Radar / Radio Antenna / GPS sensor PU and epoxy dispensing pouring filling equipment

- Depth Gauges glue potting machine epoxy potting machine 2k pu dispensing machine

- Climate control shipping container controls PCBA ab glue dispensing machine ab epoxy and hardener mixing and dosing machine

- Unmanned Underwater Vehicles (UUV) ab two component urethanes dispensing and potting machine

- 2k Mixing and dosing Unit machine for Electric Motors for Anchor Winches / Mast Controls potting and encapsulation

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mixing Equipment > Mixing Tank

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

TOM wang

Hi there! Welcome to my shop. Let me know if you have any questions.

TOM wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile