Home > Products > Other drying machine > ISO9001-2008 approved maize dryer unit

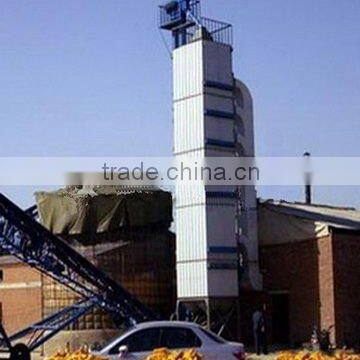

ISO9001-2008 approved maize dryer unit

- 15 Set / Sets per Month

- shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Type | Rotary Drying Equipment | Place of Origin | Henan, China | |

| Brand Name | taida | Model Number | 29348 |

Product Description

Specifications

maize dryer unitreliable operation

With nice design

Low energy consumption

ISO9001-2008,SGS

Maize dryer unit

Fair current maize dryer unit working principle:

The machine uses fair current drying technology, which uses the hot air as thermal medium to dry the grain

The internal is composed by air ventilation and horns ventilation unit, outside the unit filled with grain horns, grain, hot air flow of top-down by air ventilation quarter, down through the bread into the direction of the exhaust gas layers, horns unit

Hot air and grain flow positive, called the mixed flow

Hot air through grain layer, heat and moisture have the heat transfer with the grain: hot air to food, make temperature increased, moisture food grains heated evaporation into the air and become waste discharge

Dry bread to the heat flow down slowly, after tempering period which food grain moisture inside layer temperature and precipitation, to reach even equilibrium

After entering the food, cooling, make the grain cool down to the storage temperature, and then discharge the grain by grain period

Mixed current maize dryer unit working principle:

The machine mixed current drying technology, which uses the hot air as thermal medium to dry the grain, he internal mainly by the horns layer interlaced ventilation unit

Outside the unit filled with grain horns, grain, hot air flow of top-down by air horns, and direction through unit, the exhaust gas grain horns unit. Hot air and grain flow both positive and reverse flow, called the mixed flow

Hot air through grain layer, and heat and moisture of grain of heat transfer: hot air to food, make temperature increased, moisture food grains heated evaporation into the air and become waste discharge

Dry bread to the heat flow down slowly, after tempering period which food grain moisture inside layer temperature and precipitation, to reach even equilibrium

After entering the food, cooling, make the grain cool down to the storage temperature, and then discharge the grain by grain period

maize dryer unit performance features:

Outdoor use single, wind, and rain

For homework, mechanization, stable performance, convenient operation, saving construction investment

Adaptable, grain drying varieties

Heat recycling, reduces energy consumption

Grain drying thoroughly, and evenly, drying food can be directly into the warehouse

Good-quality and no pollution after drying

Main specification of Core dryer unit

model | TDH100 | TDH150 | TDH200 | TDH250 | TDH300 | TDH400 | TDH500 |

Capacity(ton per day) | 100 | 150 | 200 | 250 | 300 | 400 | 500 |

Range of moisture decreased(%) | 4~16 | ||||||

Heat medium | Clean air | ||||||

Hot blast temperature(°C) | < 120 | ||||||

Max temperature of grain(°C) | 55 | ||||||

Unevenness of drying(%) | < 2 | ||||||

Percertage of broken grain(%) | < 0.5 | ||||||

unit heat consumption | 5800 | ||||||

Coal consumption(standard coal)(kg/h) | 60~230 | 90~345 | 120~460 | 150~575 | 180~690 | 240~1000 | 300~1380 |

installed capacity | According to the environment and conditions, precipitation amplitude and configuration | ||||||

Overall dimension(M) | 4×3 | 4×3 | 5×3.2 | 5.5×3.2 | 5.5×4 | 5.5×4.5 | 6×6 |

height(M) | 6~1 | 8~15 | 13~17.5 | 14~18 | 14~19 | 15~20 | 16~22 |

Contact Us

- Zhengzhou Taida Mining And Metallurgy Equipment Co., Ltd.

- Contact namelulu pan Chat Now

- Phone0086-0371-86565119

- Addresshigh and new-tech industry development zone,zhengzhou,china, Zhengzhou, Henan

Product Categories

| Ball mill | Coal Gasifier | Conveyor | Crusher |

| Fertilizer machine | Granulator | Hot air furnace | Mineral dressing products |

| New Products | Other drying machine | Rotary kiln |

New Products

-

high yield groundnut desiccator

-

ISO9001-2008 approved 60 Seeds desiccator

-

ISO9001-2008 approved Straw drying

-

ISO9001-2008 approved Sausages drying machinery

-

ISO9001-2008 approved Fish dryer

-

TD-15 Rice Husk Drying Machine

-

cut your energy Cereal Tower Drying machine

-

most popular Potato drying equipment

-

most popular Cacao drying equipment

-

ISO9001-2008 approved Mushroom dryer

-

Sausages drying machine (ISO:9001:2008)

-

Fluidized bed type Vegetable drying machine

Popular Searches

- Tube Bundle Dryer

- Fluid Bed Dryer

- Dryer Equipment

- Spray Drying Equipment

- vacuum dryer

- Plate Drying Machine

- industrial dryer

- Rotary Drum Dryer

- Cross Joint Shaft

- rotary dryer

- drum dryer

- Vacuum Drying Equipment

- Rotary Drying Equipment

- Dryer Oven

- Spray Dryer

- Rotary Dryer Machine

- Industrial Rotary Dryer

- Rotary Drying Machine

- hopper dryer

- Hopper Drying Machine

- Freeze Dryer

- Industrial Centrifugal Dryer

- cowpea seed

- blood gas machine

- Drier Machine

- lab spray dryer

- Drier Equipment

- air tunnel

- air drying

- mineral dryer

Recommended Products

- Yosion Technology YH-9423A Drying Oven;Industrial Oven;Trolley Oven

- Peptide white powder spray dryer Stainless steel plant protein spray drying equipment

- Yosion Technology YH-D2000T Drying Oven;Industrial Oven;Trolley Oven

- Yosion Technology YH-9623A Drying Oven;Industrial Oven;Sample Preparation Equipment

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- .[Energy Efficiency Certified] [24KW Motor/90KG Fuel] Vacuum Dryer for Wood Chips/Straw Drying [Jinan Hengyuruntai Supplier]

- Freeze Dryer

- Vacuum freeze dryer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Chemical Drying Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

lulu pan

Hi there! Welcome to my shop. Let me know if you have any questions.

lulu pan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile