Home > Products > Surface treatment/Coating Equipment > Complete automatic hot-dip galvanizing line for fasteners coating

Complete automatic hot-dip galvanizing line for fasteners coating

- 20 Set / Sets per Month

- SHANGHAI/TIANJIN/QINGDAO

- T/T

You May Like

-

Full-automatic zinc hot immersed plating/coating of fasteners/nails/bolts/nuts/screws/drills

-

Plasma spraying coating machine/equipment

-

Plasma zinc/titanium/aluminum/chrome/nickel/alloy spray coating machine/equipment

-

supersonic plasma hot spray coating machine/equipment with sound proof room

-

Hot metal spraying/coating machine/equipment

-

Supersonic flame spraying coating machine/equipment

Product Details

| Condition | New | Type | Coating Production Line | |

| Substrate | Iron | Coating | Galvanizing | |

| Place of Origin | Shandong, China | Brand Name | REZL | |

| Model Number | RNDD-DL | Voltage | 110V/120V/127V/208V/220V /240V/380V/415V/460V | |

| Power(W) | 50-150KW | Dimension(L*W*H) | Customized Size | |

| Weight | 10 Tons | Certification | TUV | |

| Warranty | 12 Months | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

- 1. Application: to produce the fasteners in automatic actions of loading/degreasing/rinsing/pickling/flux coating/drying/hot-dip galvanizing/centrifugaling

- 2. Technology flow: workpiece→ degreasing→ rinsing→ pickling→ rinsing→ flux coating→ drying→ hot galvanizing→ centrifugaling → water cooling

- 3. Composition

a) loading barrel 1 pc

b) degreasing tank : 2 pcs

c) rinsing tank: 1pc

d) pickling tank:2pcs

e) rinsing tank : 2 pcs

f) flux coating: 1pc

g) conveyor belt drying furnace 1 set

h) rotating barrel mechanism 1 set

i) hot galvanizing tank with loading/transmission system 1 set

j) centrifugaling machine 1 set

- 4. main technical specifications:

a) size of fasteners : on request

b) zinc coating thickness: 0.04-0.06mm(ASTM/DIN/AS/ISO)

c) productivity: 1.5t/hour

- 5. Machine description

5.1Crane:1 set

material: A3 welded steel plates or H beam steels;

5.2Tank:

1) 10mm PP/PVC

2) strengthened by A3 steel to bear heavy duty;

3) tanks material and dimensions

Tanks | Material | Dimension | Quantity |

Degreasing tank | PP/FRPP With heaters, temperature controller and pipelines | 2100*2000*1500mm | 2 |

Rinsing tank | PP/FRPP

| 2100*2000*1500mm | 1 |

Pickling tank | PP/FRPP With heaters, temperature controller and pipelines | 2100*2000*1500mm | 2 |

Rinsing tank | PP/FRPP | 2100*2000*1500mm | 2 |

Flux coating tank | Stainless steel With heaters, temperature controller and pipelines | 1500*2000*1500 | 1 |

5.3V shape base:

1)non-conductive V shape bases are made of polymer PE material

2)conductive V shape bases are made of cast copper

5.4Heating/cooling system

1) Pre-treatment tanks are heated by SUS304 electrical heating pipes, be equipped with temperature controller;

2) Flux coating tanks are heated by titanium electrical heating pipes, be equipped with temperature controller.

5.5 Drying furnace

Conveyor belt transmission type

Resistance heating power: 30kw

Dimension of the furnace(L*W*H): 3000*1000*1500mm

5.6Collecting barrel rotating mechanism

2pcs of barrel installed on the rotating round table;

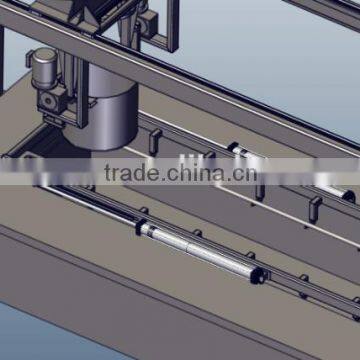

5.7Hot galvanizing loading/transmission robot

1) The robot is consists of supporting arm, which is welded on the H beam frames;

2)Loading and transmission automatically under orders

3)Barrels can be rotated and tilted for better galvanizing;

5.8Hot galvanizing tank

1)Tank material: ceramic tank/steel kettle

2)Tank dimension: 3500*2000*1500mm

3)Heating method: electrical inner heating(according to condition of customers,can be heated by natural gas or oil)

4)Zinc liquid temperature range: 450-560℃

5.9 Centrifugal machine

5.10 Scrubber system

1)sucking cover is installed above the tanks or aside of tanks,be connected by one channel;

2) wasted air treatment tower:material 10mmPP;PP filled material,water proofing film,vertical chemical pump,spraying mechanism,centrifugal fan

Contact Us

- Beijing Ron-En Machinery & Integration Co., Ltd.

- Contact nameLaura zhang Chat Now

- Phone86-010-56927698

- Address817, Bldg. 1, Floor 7, Bldg. 15, South Fangzhuang Road

Product Categories

| Construction Equipment | New Products | Other machines/parts | Pipes/Tubes Equipment |

| Surface treatment/Coating Equipment | Wire/Rod equipments |

New Products

-

Chemical wire screen welding machine

-

welded wire mesh machine

-

full automatic chain link fence machine

-

automatic mesh panel welding machine

-

mechanical type chain link fence machine

-

expanded metal mesh machine

-

Gabion mesh machine

-

Perforated-metal machine

-

Anti-climb fence welding machine

-

Why our price is cheap? CNC screen mesh pipe welding machine

-

V-wire mesh welding machine

-

CNC wedge wire mesh welding machine

Popular Searches

- spray guns

- Spraying Nozzle

- auto maintenance

- Auto Production Line Equipment

- car maintenance equipment

- Auto Production Line Machine

- Paint Production Line

- Coating Production Line

- Powder Coating Line

- gas oven

- Painting Oven

- spray booth

- car maintenance

- automobile maintenance

- paint chamber

- powder coating plant

- car coating equipment

- painting room

- Spray Booth Oven

- auto mug

- pvd vacuum coating machine

- Curing Oven

- coater

- coating machine

- Painting Machine

- Spray Gun

- Metal Coating Machinery

- plating production line

- vacuum coating equipment

- surface coating machine

Recommended Products

- SIMVACO Perovskite Solar Cell PVD Magnetron Sputtering Machine Thin Film Deposition System

- SIMVACO Perovskite Solar Cell PVD Coating Machine Thermal Evaporation Vacuum Coating

- SIMVACO High-Performance Metal Ceramic PVD Coating Machine Hard Vacuum Coating

- SIMVACO Advanced Vacuum Evaporation Coating Equipment for Automotive Lighting

- HY-K09 Large motor stator and rotor tunnel electrostatic powder spraying production line

- HY-K09 Electric toothbrush 3 small stator and rotor electrostatic powder coating machine

- SIMVACO Eco-Friendly Vacuum Evaporation Coating Machine for Plastic Christmas Products

- SIMVACO Large-Area Multi-Arc Ion Decorative Coating Machine for Metal Surfaces

- SIMVACO Horizontal PVD Coating Continuous Production Line Metal & Glass Substrate Magnetron Sputtering

- SIMVACO Large Glass Anti-Reflection Sputter Deposition Production Line PVD Coating Machine

- SIMVACO Tool Superhard Coating Ion Plating Machine Enhanced Hard Film Deposition Hardware

- powder coating machine ,coating machine,powder coating, powder output 300-400g/min,powder paint

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Coating Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Laura zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Laura zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile