Home > Products > Production line > Tooth Roll Crusher For Sale

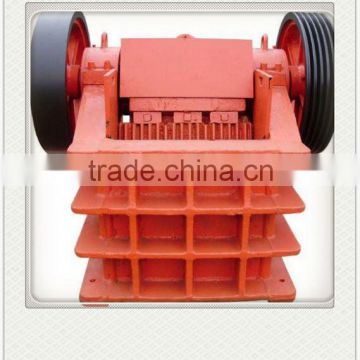

Tooth Roll Crusher For Sale

- 100 Piece / Pieces per Month

- QINGDAO TIANJIN SHANGHAI

- T/T Credit Card

You May Like

Product Details

| Condition | New | Application | Mining | |

| Motor Type | AC Motor | Capacity(t/h) | 500 | |

| Place of Origin | Henan, China | Brand Name | Prominent | |

| Model Number | PE 700* 100 H 4 | Weight | 2.8~58t | |

| Certification | ISO | Warranty | 1 Year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

Tooth Roll Crusher For Sale Long Service Life, Large Feeding Size, Stable Can do Hard Stones, Life Time Support,Jaw crusher pre-start checks whether the ore crushing cavity or other debris should be removed immediately. Jaw crusher before starting guards should carefully check is good, found to be unsafe, should immediately eliminate it.After Tooth Roll Crusher For Sale start, if found to have unusual circumstances, should be immediately stopped, the reason to exclude risks to be identified before they start again. After XINGHAO Tooth Roll Crusher For Sale normal operation before feeding. Be crushed material should be uniform to join the crushing cavity, and should avoid feeding side, to prevent the sudden increase in load mutation or unilateral. After XINGHAO Tooth Roll Crusher For Sale normal operation before feeding. Be crushed material should be uniform to join the crushing cavity, and should avoid feeding side, to prevent the sudden increase in load mutation or unilateral of Tooth Roll Crusher For Sale

After Tooth Roll Crusher For Sale start, if found to have unusual circumstances, should be immediately stopped, the reason to exclude risks to be identified before they start again Lubrication jaw crusher can often work and timely attention to ensure the normal operation of the friction surface and extend the life of the equipment. Add as 50-70%, the carrying capacity of oil must be replaced every three months, oil change, application of clean gasoline or kerosene carefully cleaned roller bearings. Bracket and bracket pad contact, before oil began to enter the crusher. Because of its simple structure, reliable operation, easy maintenance and repair, as well as low cost, present in our mines are widely used, basically use it to crushing hard and medium hard ore (rough broken and in pieces)

Features

Tooth Roll Crusher For Sale Long Service Life, Large Feeding Size, Stable Can do Hard Stones,

Tooth Roll Crusher For Sale Operation Notes:

Because of the low initial high manganese steel hardness, low yield strength, impact strength in the non-conditions, the work hardening is not sufficient, easy flow and are cutting. To improve the life of the jaw, the development of the Sino-manganese steel. The steel was first invented by the Climax Molybdenum Company, and in 1963 officially included in the US patent. Its cast microstructure of austenite and martensite and a small amount of pearlite, the water toughening treatment, their organizations into a single austenite or austenite + a small amount of undissolved carbides (depending on the carbon content) tissue. Since then people have done a lot of research in manganese, that its hardening mechanism is: after lower manganese content, the austenite stability decreased in impact or abrasion, the austenite-prone strain-induced martensitic transformation, so that the wear resistance [4,7,8]. The manganese component is generally: 0��7% ~ 1.2% C, 6% ~ 9% Mn, 0.5% ~ 0.8% Si, 1.2% Cr, and other trace elements such as V, Ti, Nb, RE and the like. In manganese steel jaw in practical applications has also made good use of effects, such as the ratio of manganese steel jaw life increased by more than 20% [4,9,10] crushing silica, while the cost of high-manganese steel jaw quite. Therefore, in the medium and small jaw crusher used in manganese steel is a material worthy of the jaw.

Maintenance & Attention

Impact crusher hammer wear only appear in Looking materials side. When the rotor speed is normal, the feed will drop to the board hammer surface (of attack), the back and side panels are not being worn hammer. Even Looking material this side rarely wear. And the bottom of the ground rods are also more easily Change. Crusher hammer metal utilization can be as high as 45% -48%. The hammer crusher hammer was hanging state, wear occurs on the front, rear and side relative to the plate hammer, hammer wear more serious, hammer metal utilization reached only about 25%. And the rotor body itself may be worn. Work at the bottom of the sieve hammer crusher wear seriously affected, grille To replace all, and also more complicated to replace sieve

To Choose a Right Tooth Roll Crusher For Sale

Optional spring cone crusher is also noted that when the feed size and equipment of the nesting size, shape and size of these parts directly affects the operational efficiency of the cone crusher. If the spout is too big or too small, so that operating power greatly increased, it may lead to substandard materials and components cone crusher for a great deal of damage.

Contact Us

- Zhengzhou Prominent Technology Co., Ltd.

- Contact nameTina Qi Chat Now

- Phone86-371-86706036

- AddressWENHUA ROAD, Zhengzhou, Henan

Product Categories

| Lab Equipment | Machinery | New Products | Photo Communication |

| Production line | Turnkey Project Service |

New Products

-

Teeth Roll Crusher

-

Stones Primary Jaw Crusher

-

Stone Shaft Impact Crushing Machine

-

Sugar Beta Manufacturing Process Production Line

-

Turnkey Stone Crusher Plant

-

Tough / soft biscuit production line

-

Cookies Extruder

-

Taosu biscuit machine

-

Diced Swiss roll production line

-

Pie / Muffin production line

-

Cake automatically sent Machine

-

Hard candy production line casting

Popular Searches

- Vertical Shaft Impact Crusher

- Jaw Crusher

- Cast Basalt

- coal mine

- gold mine

- copper ore

- quick production plant

- copper slag

- Hydraulic Cone Crusher

- Cone Stone Crusher

- Mobile Crusher

- Rock Jaw Crusher

- Disc Shear

- hammer crusher

- Cone Machine

- Stone Jaw Crusher

- Impact Crusher

- stone crusher

- rock crusher

- crushing plant

- Jaw Crusher Machine

- Cone Crusher

- crusher machine

- sand maker

- Casting Machine Ccm

- soft coal

- crushed limestone aggregate

- stone crushing station

- quarry

- rock processing

Recommended Products

- Stationary type pedestal boom system

- Stationary Type Pedestal Breaker Boom System

- Hydraulic excavator slotting machine trenching machine trenching machinery

- Tunnel specific milling excavator Excavator Tunnel specific milling

- Milling excavators can be widely used for excavating tunnels, ditches, and municipal pipelines

- Excavator milling excavator for precise construction, especially suitable for tunnel excavation

- Excavators, milling machines, and excavators produce uniformly distributed material particles that can be directly used as backfill material

- Excavator milling excavator has a wide range of applications and is suitable for rocks of various hardness

- The hydraulic motor of excavator milling excavator has a small volume

- The milling excavator can break and excavate Slotting, milling and planing

- Pedestal Rockbreaker System, A Reliable Partner for Industrial Production

- pedestal rock breaker boom system

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Mining Crusher

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tina Qi

Hi there! Welcome to my shop. Let me know if you have any questions.

Tina Qi

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile