Home > Products > Hot work tool steel > 4cr5mosiv1 H13 1.2344 Skd61 Steel Round Bar

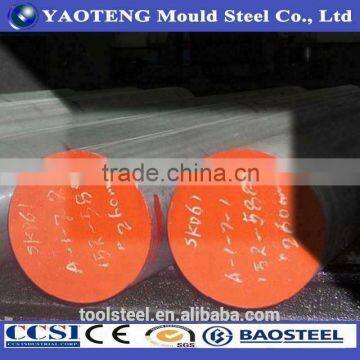

4cr5mosiv1 H13 1.2344 Skd61 Steel Round Bar

- shenzhen

- T/T L/C D/P D/A Credit Card PayPal

You May Like

-

Hot Die Steel H13 Skd11

-

H11 Tool Steel | 1.2343 | SKD6 Hot Work Steel-Special Steel China Supplier

-

SAE Carbon Aisi 1045 Steel Price-steel Round Bars

-

1045/S45C/st37-2 Equivalent Steel Material Quality Choice

-

Hss Steel Price, M2 Tool Steel, M2 High Speed Steel Quality Choice

-

S235JR/Q235/A36 MS Steel Flat Bar, Flat Bar Steel, Steel Flat Bar

Product Details

| Steel Grade | SKD61 | Standard | AISI, ASTM, BS, DIN, GB, JIS | |

| Dimensions | round 8-500mm/ flats 10-90X 100-610 mm | Place of Origin | Guangdong, China | |

| Brand Name | FT or OEM | Model Number | SKD61 | |

| Technique | Forged | Application | Tool Steel Bar | |

| Alloy Or Not | Is Alloy | Special Use | Mold Steel | |

| Type | Alloy Steel Bar |

Product Description

4cr5mosiv1 h13 1.2344 skd61 steel round bar

4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel stockholders and suppliers, delivering to the whole of the china. YAOTENG Steel are suppliers of 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel in round bar, diameters and plate, cut to your requirements. As a reliable hot work steel it is suitable for a wide variety of applications. It combines very good red-hardness with toughness and tools may be water-cooled in service. 4cr5mosiv1 h13 1.2344 skd61 steel round bar may be cold-hobbed in the annealed condition.

We welcome export enquiries for tool steel. Please contact our sales office and consult our shipping policy for further details.

Related Specifications

AISI ASTM A681 DIN 17350 BS EN ISO 4957

|

| Form of Supply | YAOTENG Steel are stockholders and suppliers of 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel round bar and flat sections which can be sawn cut to your required sizes. 4cr5mosiv1 h13 1.2344 skd61 steel round bar ground steel bar can be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel is also available produced as Ground Flat Stock / Gauge Plate, in standard and non standard sizes. |

| Applications | Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners, mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. 4cr5mosiv1 h13 1.2344 skd61 steel round bar is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies. |

| Forging | Preheat slowly to 750°C then increase the temperature more rapidly to 1050-1100 °C. Do not forge below 850°C. It is essential to cool the 4cr5mosiv1 h13 1.2344 skd61 steel round bar slowly after forging, either in a furnace or in vermiculite. |

| Annealing | Soak thoroughly at 840-860°C before furnace cooling at a maximum rate of 20°C per hour down to 600°C followed by cooling in air. |

| Stress Relieving | When tools made from 4cr5mosiv1 h13 1.2344 skd61 steel round bar are heavily machined or ground , the relief of internal strains is advisable before hardening to minimise the possibility of distortion. Stress relieving should be done after rough machining. To stress relieve, heat the component carefully to 700°C, allow a good soaking period (two hours per 25mm of ruling section). Cool in the furnace or in air. The tools may then be finish machined before hardening. |

| Hardening | Preheat to 780-820°C. Soak thoroughly, then increase rapidly to the final hardening temperature of 1000-1030°C. When the 4cr5mosiv1 h13 1.2344 skd61 steel round bar has attained this temperature, soak for approximately thrity minutes. Cool in air. Large sections may be quenched in oil. To reduce scaling or decarburisation, we recommend isothermal molten salt bath treatment. Preheat in salt at 780-820°C then transfer to salt bath standing at 1000-1030°C. Soak and quench into salt standing at 500-550°C. Allow to equalise, withdraw and cool in air. Alternatively, this tool steel may be vacuum hardened or pack hardened. Tools should be tempered as soon as they become hand warm. |

| Tempering | Heat uniformly to the required temperature allowing a soaking time of two hours per 25mm of ruling section. Withdraw from the furnace and allow to cool in air. A second tempering is strongly recommended, the 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool being allowed to cool to room temperature between tempers. The usual tempering range is 530-650°C depending on the hardness requirements and the operating temperature of the tool.

|

| Welding | In general, we do not advise the welding of tool steel but users sometimes prefer to weld in order to avoid the cost of retooling. It should be remembered that this grade is an air hardening steel and that in welding the area of the weld attains a temperature of about 1000°C. Cracking is likely to occur during cooling unless proper precautions are taken. Popular methods of welding are atomic hydrogen and argon arc. We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding tool steels. Welding Procedure 1) It is desirable to anneal the tool prior to welding but with care welding may be done on hardened and tempered tools. |

| Nitriding | 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel can be nitrided to give a hard surface case. The steel is then very resistant to wear and erosion. Nitriding also increases resistance to corrosion. Nitriding in ammoniac gas at a temperature of 525°C will give a surface hardness approximately 1000 to 1250HV. Before nitriding the tool should be hardened and tempered at approximately 50°C above the nitriding temperature. It is important to note that with increase in penetration of the nitriding, there is a reduction in resistance to thermal shock and an increase in embrittlement.

|

| Heat Treatment | Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of tool steels. |

| Final Grinding | Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure the grinding wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a copious supply of coolant. If dry grinding is resorted to then use a very soft wheel. |

| Quality Assured Supply | 4cr5mosiv1 h13 1.2344 skd61 steel round bar tool steel is supplied in accordance with our ISO 9001 : 2008 registration. |

Contact Us

- Dongguan City Yaoteng Special Steel Co., Ltd.

- Contact nameJack Tan Chat Now

- Phone86-0769-33232622

- AddressDongGuan city, GaoBu town, GaoLong read YiFang, Dongguan, Guangdong

Product Categories

New Products

-

Free Sample Aisi 4140 Steel, 4140 Round Bar, Sae 4140 Steel Price

-

1045 Steel /s45c Material 1045 High Carbon Steel Forged Carbon Steel 1045

-

Steel H13 Material Round Bar, H13 Steel Plate China Supplier, H13 Steel Bar

-

SKD11 Hot Rolled 12mm Steel Rod Price , SKD11 Die Steel Bar, 1.2379 Steel Round Bar Quality Choice

-

Hot Forged HSS M42 Steel , High Speed Tool Steel Bars

-

P20 Tool Steel|1.2311|3Cr2Mo Plastic Mold Steel Plate Quality Choice

-

Din 1.2311 Plastic Mold Tool Steel Sheet

-

EN31 Special Steel , Bearing Steel SUJ2, 52100 Round Bar Price

-

Steel Material Skd61, 1.2344 Steel, Skd61 Steel

-

Cr8Mo2VSi DC53 Steel

-

D3 Steel Price per Kg, D3 Alloy Steel Buy From China, D3 Steel Round Bar China Manufacture

-

42crmo4 Steel Price, 42crmo4 Alloy Steel Round Bars, 42crmo Chemical Composition of Alloy Steel

-

China Suppliers Aisi 1045 Alloy Steel Bar, Carbon Steel Price per kg

-

M2 Steel, m2 Tool Steel Supplier, M2 High Speed Steel

-

Sae 1020 Carbon Steel Bar, Steel 1020, 1020 Steel

-

Free Sample Aisi 4140 Carbon Alloy Steel Round Bars, 4140 Alloy Steel, Steel Aisi 4140

-

4140 Alloy Steel, 1.7225 Steel Material, SCM440 Bahan Setara

-

Steel Din 1 7225, SCM440 Bahan Setara, 4140 Alloy Steel Round Bar

-

Factory Price H13 Tool Steel, H13 Hot Die Steel, H13 Material

-

Forged Connecting Rod SAE AISI 4340 Steel Bars Price

-

S136 Weight of 12mm Thick Steel Plate

-

China ASTM1.2311 Plastic Steel / 2311 Mould Steel Plate / P20 Mold Steel

-

High Precision Steel Bar / Rod 2083 / 2316 Plastic Steel / Plastic Mould 420

-

P20 Steel Specification

Popular Searches

- alloy round bar

- steel roofing sheet

- special steel

- alloy steel

- round bar

- die steel

- steel bar

- hot rolled bar

- round steel

- surface bar

- steel profile

- forged steel

- forged bar

- carbon steel plate

- carbon steel pipe

- carbon steel coil

- smokeless charcoal

- timekeeper

- alloy bar

- high pile

- tool steel

- mould steel

- plastic mould steel

- cold work tool steel

- lacquered plate

- black annealed

- plastic bar

- black rod

- silicone sheet

- spangle

Recommended Products

- 310S Stainless Steel Bar, 2205 2507 Round Steel for Industrial Construction, Brushed Finish

- Duplex Stainless Steel Rods, 2205 and 2507 Stainless Steel Round Bars, and Mechanical Spare Parts

- 2507 Black Rod Bright Rod SUS321 Stainless Steel Rod for Auto Parts Long Life Manufacturer Supply

- Duplex Stainless Steel 2507 2205 Round Bar, for Petrochemical Industry, Bright Bar, Stainless Steel Wire Supplier

- 304L 2507 347H 317 Stainless Steel Round Bar Steel Bar Round Cold Drawn Solid Round Bar Custom Made

- Super Grade Electrical Pure Iron Hot-Rolled Bar With Stable Magnetism, No Aging, Excellent Workability

- Electrical Pure Iron Bar Compatible With DC Motors, Magnetic Shielding, and Defense Applications, Low Coercivity Hc≤96A/m

- High-Purity Electrical Pure Iron Round Steel for Relay Cores and Electromagnetic Components in Telecommunications

- Electrical Pure Iron Hot-Rolled Wire Rod Coil, Diameter ?6.5mm-42mm, GB/T 6983-2008, DT4C Grade for Industrial Use

- Electromagnetic Pure Iron Hot Rolled Round Steel for High-Performance Magnetic and Electrical Equipment Industrial Pure Iron Round Steel

- Electromagnetic Pure Iron Hot Rolled Round Steel for Electrical Industry and Magnetic Equipment

- Electrical Pure Iron Round Steel, DT4C Bar for Electromagnetic and Electrical Applications

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Round Bar

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jack Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Jack Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile