Home > Products > Hot work tool steel > Hot Work Die Steel H13 /1.2344 Round Bar steel price per ton

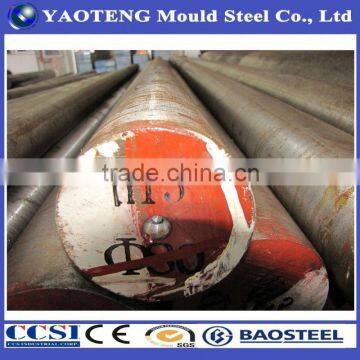

Hot Work Die Steel H13 /1.2344 Round Bar steel price per ton

- Shenzhen Port or Guangzhou Port

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Steel Grade | H13 | Standard | AISI, ASTM, BS, DIN, GB, JIS | |

| Dimensions | Dia : 1mm--900mm | Place of Origin | Guangdong, China | |

| Brand Name | OT | Model Number | H13 | |

| Technique | Hot Rolled | Application | Other, Die Steel Bar, Pressure Die Casting Aluminium & Copper ExtrusionDie Forging | |

| Alloy Or Not | Is Alloy | Special Use | Mold Steel | |

| Type | Other, hot work die steel |

Product Description

| |||||||||||||||||||

1.ChemicalComposition(%) |

| ||||||||||||||||||

2.Equivalent Grades |

H11/4Cr5MoSiV/SKD6 | ||||||||||||||||||

3.Form&SiZE |

| ||||||||||||||||||

4 Shape of the products |

1,round : forged steel , rolled steel , drawing steel ,polishing steel 2,Abnormal shape : quadrilateral steel, hexagons steel . 3,Flat steel | ||||||||||||||||||

5. Heat Treatment |

H13 tool steels are preheated to 816°C (1500°F). Then the steels are directly heated by increasing the temperature to 1010°C (1850°F) followed by holding for 15 to 40 mins. The steels are then air-quenched. | ||||||||||||||||||

| |||||||||||||||||||

7. Forging | H13 tool steels are forged at 1079°C (1975°F). For this type of steels, forging below 898°C (1650°F) is not preferable. | ||||||||||||||||||

8. Annealing |

H13 tool steels are annealed at 871°C (1600°F) and slowly cooled at 4°C (40°F) in the furnace. | ||||||||||||||||||

9. Tempering | Tempering is carried out in H13 tool steels from 538 to 649°C (1000 to 1200°F) to obtain Rockwell C hardness of 53 to 38. Double tempering can also be performed in these steels for every one hour at the preferred tempering temperature. | ||||||||||||||||||

10. Stress Relieving | When tools made from H13 tool steel are heavily machined or ground , the relief of internal strains is advisable before hardening to minimise the possibility of distortion. Stress relieving should be done after rough machining. To stress relieve, heat the component carefully to 700°C, allow a good soaking period (two hours per 25mm of ruling section). Cool in the furnace or in air. The tools may then be finish machined before hardening. | ||||||||||||||||||

11. Highlight advantage | high hot strength and hardness

--good resistence to heat, good hot toughness, high resistance to temperature fatigue and wear in medium heat

--small heat deformation

--the tendency of the appearing of iron oxide skin are small in air-quenching

--excellent corrosion resistance | ||||||||||||||||||

H13 Steel product details and application

warehouse steel stock- Yaoteng Mould Steel Co.,Ltd

Sales merchandiser:Winnie

Tel:+86-0769-33899333

E-mail:winnie AT toolsteel DOT net DOT cn

winnie AT otaisteel DOT com

Skype:928469037

Company Address: 3 fang,xiansha,Gaobu town,Dongguan City

Contact Us

- Dongguan City Yaoteng Special Steel Co., Ltd.

- Contact nameJack Tan Chat Now

- Phone86-0769-33232622

- AddressDongGuan city, GaoBu town, GaoLong read YiFang, Dongguan, Guangdong

Product Categories

New Products

-

AISI H13 standard steel plate sizes

-

h13 efs mould steel aisi h13 efs mould steel detai

-

tool steel skd61 tool steel round bars

-

steel punch pin

-

h13 mandrel bar

-

forged steel bar in wuhan china 1.2343/x38crmov5-1

-

Top quality H13//1.2344/SKD61 tool steel plate h13 steel flat bar

-

Quality Raw Material H13 die steel round bar from Yaoteng Trade Company

-

h13 steel forged round bars 34crnimo6 q t

-

w300/ 1.2343/ h11

-

experience certificate

-

Free sample H11 hot work tool steel

Popular Searches

- Alloy Round Bar

- Steel Roofing Sheet

- special steel

- alloy steel

- round bar

- die steel

- steel bar

- carbon pipes

- hot rolled bar

- Round Steel

- surface bar

- steel profile

- forged steel

- forged bar

- Carbon Steel Plate

- Carbon Steel Pipe

- Carbon Steel Coil

- Smokeless Charcoal

- timekeeper

- Alloy Bar

- high pile

- tool steel

- mould steel

- Plastic Mould Steel

- Cold Work Tool Steel

- lacquered plate

- black annealed

- plastic bar

- Black Rod

- galvanized sheets

Recommended Products

- Alloy Steel Round Bar - Diameter Options | Customizable Lengths

- High Speed Steel Cobalt Tool Bits

- Square/Rectangular High Speed Steel Tool Bits

- HSS M35 1.3243/HS6-5-2-5 Skh55 Tool Steel Round Flat Bar Manufacturer Mold Steel

- M35/Skh55/1.3243 High Speed Steel Forged HSS Steel Flat Bar/Forged Mold Steel Round Bar/Mold Steel Plate for Cutting

- High Speed Steel Plate M2 Skh51 DIN1.3343 Factory Price HSS Steel Sheet M2 M35 High Speed Steel Plate

- T5 Tool Steel/Skh4/2756/W18cr4V2co8/ HS 18-1-2/1.3265 HSS High Speed Tool Steel Forged and Rolled

- M2 Skh51 High-Speed Steel Round Bar for Cutting Tool Die Stamping Flat Annealed Wear Resistance Milled Surface Four Sides Cut

- M390 Pm204 Powder Mold Steel High Speed Steel for Knife Cutting

- High Speed Steel Plate M2 Skh51 DIN1.3343 Factory Price HSS Steel Sheet M2 M35 High Speed Steel Plate

- M35 Tool Steel/Skh55/HS6-5-2-5/1.3243 High Speed Steel Forged and Hot Rolled

- AISI M7 DIN1.3348 High Speed Steel Foged and Hot Rolled Round Bar Flat

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Round Bar

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jack Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Jack Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile