Home > Products > Benefication equipment > Evenly Feeding Materials To Ball Mill Electromagnetic Vibrating Feeder

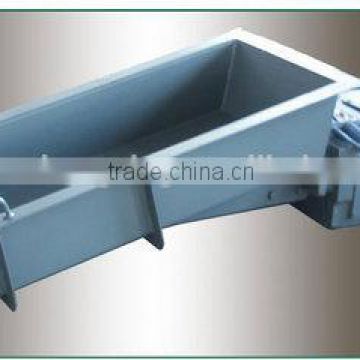

Evenly Feeding Materials To Ball Mill Electromagnetic Vibrating Feeder

US$ 500.00 - 500.00

/ Set

1 Set(Min. Order)

- QingDao/TianJin

- T/T

You May Like

Product Details

| Condition | New | Application | Stone,quarry,mining | |

| Power Type | Electric | Capacity(t/h) | 1-100t/h | |

| Place of Origin | Henan, China | Brand Name | Hengxing | |

| Model Number | GZ1,GZ2,GZ3,GZ4,GZ5 | Power(W) | depending on different model | |

| Dimension(L*W*H) | depending on different model | Weight | depending on different model | |

| Certification | ISO9001:2008,CE | Warranty | One Year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Product Description

Evenly Feeding Materials To Ball Mill Electromagnetic Vibrating Feeder:

Processing ability: 5–100 t/h

Feeding size: 50–150 mm

Power: 60–650 w

Voltage: 220 v

Applied material: powdery, granular materials, etc

Electromagnetic vibrating feeder is used for evenly and quantitatively feeding the materials from the storage bin or other storage machines to the material receiving equipment and it is the indispensable equipment to realize the automation of the line production. It is divided into open type and closed type. Our company can produce electromagnetic vibrating feeder, hopper and conveying machine according to the customers’ requirements.

Working Principle:

Electromagnetic vibrating feeder uses the resonance principle of mechanical vibration and the double plastids work in the below critical and resonance state. The materials inside the material chute are continuously thrown up during the feeding process and move forwards along the track of a parabola. The control equipment of this series of electromagnetic vibrating feeder adopts silicon controlled half-wave rectification circuit, for this reason; during the using process, it can conveniently adjust the feeding amount through adjusting the silicon controlled open angle and realize centralized control and automatic control of the production flow.

Electromagnetic vibrating feeder uses the resonance principle of mechanical vibration and the double plastids work in the below critical and resonance state. The materials inside the material chute are continuously thrown up during the feeding process and move forwards along the track of a parabola. The control equipment of this series of electromagnetic vibrating feeder adopts silicon controlled half-wave rectification circuit, for this reason; during the using process, it can conveniently adjust the feeding amount through adjusting the silicon controlled open angle and realize centralized control and automatic control of the production flow.

Techncial Parameter

Detailed Images

Factory Workshop

Contact

Ms Sara

Mobile phone(whatsapp): 0086 137 8347 1727

Skype: sarapang6

Wechat: sarapang6

Email: sales006#

Contact Us

- Zhengzhou Hengxing Heavy Equipment Co., Ltd.

- Contact nameSara Pang Chat Now

- Phone0086-371-67858720

- AddressNo.8 Hongye Road.West Hehuan Street. High -Tech Development Zone. Zhengzhou.China, Zhengzhou, Henan

Product Categories

New Products

-

Alluvial Gold Washing Plant Mining Shaking Table

-

Gold Diaphragm Jig Machine

-

Gold Concentrate Machine Shaker Table

-

Gld Processing Plant With Cyanide Leaching Process

-

Low Cost Gold Wash Table

-

Mining Equipment Thickener Tank

-

High Efficiency Center Drive Sludge Thickener

-

Zircon Ore /Ziron Sand Spiral Chute

-

Rock Gold,Placer Gold Concentration Shaing Table

-

Spiral Sand Classifier For 200 Mesh Size Classification

-

Mineral Separator Hydrocyclone Price With Discount

-

High Efficiency Thickener For Liquid Detergents

-

4000 Gauss Wet Magnetic Drum Separator For Quartz Sand

-

Mining Gold Concentration Shaking Table With High Recovery Rate

-

High Intensity Dry Magnetic Drum Separator For Quartz Sand

-

Spiral Chute Separator For Gold Wash Plant

-

Placer Gold Shaking Table With High Recovery Rate

-

Mineral Use Hydrocyclone For Tailings Dry Heaping

-

High Intensity Dry Type Magnetic Drum Separator

-

Alluvial Gold Shaking Table Price For Cleaning Process

-

Placer Gold Shaking Table For Sale

-

Jigger Machine For Manganese Ore Gravity Separation Processing Plant

-

Rock Ore Gold Mining Machine /Gold Mining Equipment With Carbon In Leaching Process

-

High Intensity Dry Magnetic Separator For Silica Sand/Feldspar Iron Removing

Popular Searches

- rotary station

- feeder shaped

- motor vibrating feeder

- stone feeder

- mining feeder

- bar feeder

- ore dressing machine

- food bowl feeder

- tiny feeder

- dressing machine

- belt conveyor feeder

- auto bar feeder

- pass feeder

- auto bowl feeder

- vibratory bowl feeder

- automatic shrimp feeder

- vibrator feeder

- linear vibrating feeder

- mining vibrating feeder

- tray feeder

- feeder grizzly

- machine vibrating bowl

- vibratory feeding machine

- automatic vibratory bowl feeder

- screw vibratory bowl feeder

- vibro feeder

- screw vibratory feeder

- flexible feeder

- vibratory feeder bowl

- heat disassembly

Recommended Products

- Yosion YX-ZDTS1400 Bucket Elevator;Lifts Samples;Hydraulic Lifting;Sample Preparation Equipment

- FZC Series Vibrating Mining Machine

- Belt Feeder

- Rod Vibrating Feeder

- ZG Vibrating Feeder

- K3 Reciprocating Coal Feeder

- HGM Activated Vibration Coal Feeder

- CZG Type Dual Mass Vibrating Feeder

- CYPB Quantitative Disc Feeder

- Electromagnetic Feeder

- ZSW850 Electromagnetic Mining Vibrating Grizzly Screen Feeder Price

- Hanging Vibrating Feeder Screw ZSW Series Vibration Feeder For Quarry Stone

Find Similar Products By Category

- Manufacturing & Processing Machinery > Feeder > Vibrating Feeder

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Zhengzhou Hengxing Heavy Equipment Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Sara Pang

Hi there! Welcome to my shop. Let me know if you have any questions.

Sara Pang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile