Home > Products > microwave device > Microwave Multifunctional Dynamie Extraction Production Line

Microwave Multifunctional Dynamie Extraction Production Line

- Shanghai

You May Like

-

Main Machine of Microwave Extraction Pilot-Plant Equipments

-

Microwave Multifunctional Extraction Pot

-

Tunnel type Microwave Chickpea Continuous Drying Machine

-

Tunnel Microwave Dryer / Moringa Leaf Drying Machine

-

Tunnel Microwave liquid sterilizing machine

-

Speedy tunnel microwave liquid sterilizing machine

Product Details

| Condition | New | Type | Dry Cabinet | |

| Place of Origin | Gansu, China | Brand Name | Huayuan | |

| Model Number | HWC-0.5 | Voltage | 380V | |

| Power(W) | 20kw | Weight | 1200kg | |

| Warranty | one year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

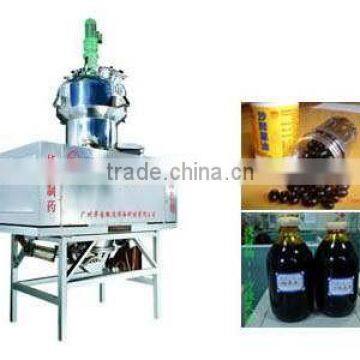

Microwave Multifunctional Dynamie Extraction Production Line

Scope of Application:

This machine is mainly used in the working shops of pharmaceutical, food processing and chemical industries etc. Microwave dynamic multifunctional extraction pot is the up-to-date product to supersede various multifunctional extraction pots widely used in the domestic.

Main Characteristics:

Traditional heat extraction adopts heat conduction and heat radiation etc. to transfer heat from outside to inside. However, microwave assistant extraction adopts inside and outside heating simultaneously. Because there is no high-temperature heat source, heat gradient is eliminated. So, it makes the extraction quality increased greatly, and effectively preserves the functional components of foods, medicines and other chemical materials. It has many advantages, for example, low extraction temperature, not easy to be burnt; there is no thermal inertia and thus it can be easily controlled and all parameters can be data presentation. It can completely meet the production modernization requirements in the pharmacy industry. Compared with generaleral extraction pot, microwave dynamic multifunctional extraction pot has the following advantages: low extraction temperature, rapid speed, high efficiency of extraction, good quality of extracts, not easy to be burnt, small usage of solvent, low operating cost, strong controllability, no pollution, and economized working space etc.

Structural Features:

(1) On the whole, its design and installation are safe, steady, reliable and hygienic, as well as easy to operate and maintain. Microwave heater and relevant components are all made of good quality stainless steel. Flawless control function and testing function are supplied.

Thermocouple temperature measurement is set to monitor the heating of materials strictly. If temperature exceeds, an alarm will be given.

PLC with man-machine interface controlling is used. Its operation is very simple And fit for everyone

This machine group adopts dynamic extraction method, accompanied with mixing and compellent reflux system. Steam can pass through the below interlayer. When microwave is open, steam can be heated to the boiling point at the same time. Then, steam is closed and materials are boiled and decocted under the condition of microwave constant temperature. As a result, it spends short time but medicinal juice has very well effective components.

(2)Advanced microwave structure:

Multi-port microwave feed in is adopted, which is beneficial to the uniformity of material heating.

Advanced microwave engineering CAD software package design is used. Reasonable makeup of microwave unit chambers. Cooling detection system adopts 2M210 specific simulative antenna to test every feed in one by one, so as to achieve the high efficiency of whole machine.

As several microwave tubes work in a same chamber, microwave antenna array technology is needed so as to ensure the multi-combination project of magnetic-control array and eliminate electronic warfare between microwaves. In China, only a few of professional microwave manufacturers can control this kind of technology. It can make magnetron work more steadily and

extend the expiration date of magnetron, so as to ensure efficiency of the whole machine.

Microwave leakage index meets the requirements of European and American national standard, and now it is the strictest standard in the domestic.

Fully Automatic. Japan Mitsubishi PLC Controlling System is adopted. Frequency Controlled and Stepless Speed Regulation

(Note: WTD-3.0 and WTD-0.5 are not equipped with steam heating device. The rest can be heated by microwave and steam synchronously, and then be extracted in the condition of microwave constant temperature

Technical Parameters:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Contact Us

- Shanghai Paikerui Packing Machinery Co., Ltd.

- Contact nameJack Yuan Chat Now

- Phone86-21-58647308

- AddressRoom 217, Building 2, No. 11, Lane 730, Chuantu Road

Product Categories

| microwave device | New Products | solid preparation machine | suppository machine |

New Products

-

Industrial continuous microwave drying and sterilizing machine

-

GWM-3W Drying and Sterilizing Machine

-

30KW 3-layer tunnel microwave drying and sterilizing machine

-

Kiwi Fruit Microwave Vacuum Drying Machine

-

Rose Microwave Vacuum Drying Machine

-

Wheat/Corn/Rice/Grain Microwave Drying Machine

-

Dried meat floss microwave drying sterilization equipment

-

Industrial Extract Microwave Vacuum Dryer

-

Apple Crisp Microwave Vacuum Drying Machine

-

batch type microwave vacuum fruit drying machine

-

Industrial microwave vacuum dryer of mango chip

-

Rice Microwave Drying Machine

Popular Searches

- Tube Bundle Dryer

- Fluid Bed Dryer

- Dryer Equipment

- Spray Drying Equipment

- vacuum dryer

- Plate Drying Machine

- industrial dryer

- Rotary Drum Dryer

- Cross Joint Shaft

- rotary dryer

- drum dryer

- Vacuum Drying Equipment

- Rotary Drying Equipment

- Dryer Oven

- Spray Dryer

- Rotary Dryer Machine

- Industrial Rotary Dryer

- Rotary Drying Machine

- hopper dryer

- Hopper Drying Machine

- Freeze Dryer

- Industrial Centrifugal Dryer

- cowpea seed

- blood gas machine

- Drier Machine

- lab spray dryer

- Drier Equipment

- air tunnel

- air drying

- mineral dryer

Recommended Products

- Yosion Technology YH-9423A Drying Oven;Industrial Oven;Trolley Oven

- Peptide white powder spray dryer Stainless steel plant protein spray drying equipment

- Yosion Technology YH-D2000T Drying Oven;Industrial Oven;Trolley Oven

- Yosion Technology YH-9623A Drying Oven;Industrial Oven;Sample Preparation Equipment

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- .[Energy Efficiency Certified] [24KW Motor/90KG Fuel] Vacuum Dryer for Wood Chips/Straw Drying [Jinan Hengyuruntai Supplier]

- Freeze Dryer

- Vacuum freeze dryer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Chemical Drying Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jack Yuan

Hi there! Welcome to my shop. Let me know if you have any questions.

Jack Yuan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile