Home > Products > mixer machine > Vacuum Ink Filling Machine-----auto Vacuum Ink Filling Maching Vacuum Maching

Vacuum Ink Filling Machine-----auto Vacuum Ink Filling Maching Vacuum Maching

- Shanghai/Ningbo

- T/T

You May Like

-

Vacuum Ink Filling Machine-----seimi Auto Vacuum Ink Filling Machine Ink Vacuum Machine

-

Three Rollers Grinder-----Hydraulic Three Roller Mill

-

Bead Ball Mixer-------KH-High Viscosity Vertical Internal Colling Mixer Ball

-

Three Rollers Grinder-----Hydraulic Heating Type Three Roll Mills

-

Three Rollers Grinder-----HS Series Granite Three Rollers Mill Series Granite Rollers

-

Three Rollers Grinder-----SJR Heading Three Roll Mills Series Three Roll Mills

Product Details

| Brand Name | HUPC | Model Number | filling | |

| Place of Origin | Zhejiang, China |

Product Description

Specifications

1kg 15cm*7cm2.5kg 18cm*8cm

biggest size 20cm*13cm

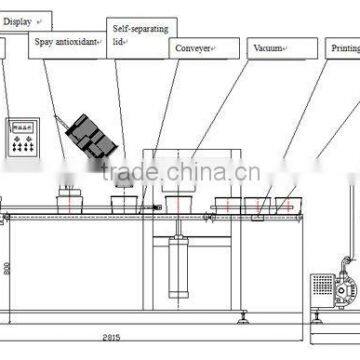

vacuum ink filling machine-----auto vacuum ink filling maching

1. Summarize

1.1 This line is integration both PLC program and pneumatic technology capably for 1and 2.5kg container to complete more than ten working procedure like filing by weighing ,vacuum sealing and printing ...,The line has greatly improved production efficiency.

1.2 put 50 cans and 50 lids on the shelf then join the pipeline to the filling gun then start the machine will be operated follow :

1.2.1 self-separating the can and move to the electronic balance.

1.2.2 open the valve and the filling to be stopped when reaching the number then move to the platform for spraying .

1.2.3open the valve to spray well-proportioned fog on the surface and again move to the lid platform

1.2.4 the lid will be self-putting and move to vacuum area.

1.2.5 the can will be carried to the vacuum room when reach the numerical value (usually -90 Kpa) and nitrogen (usually -30 Kpa) and then sealing (usually 1 secs.) all the numerical value should set in advance. Then open both drain tap and vacuum room to move to the printing area .

1.2.6 printing the can on the bottom then convey for box up.(we will buy the cartoner specialy)

1.2.7 when to pack other size container it should adjust some position and change both separation equipment for can and lid as well as bottom plate in vacuum room.

1.2.8 we will supply some filling gun and pipeline connection at customer’s request for quite more colors printing inks.

1.2.9 we also supply hopper where to connect the three –roll machine and delivery pump ,pipeline as well as filling gun.

The power source for pump and pipeline connection etc all join conveniently .

2. Technology Data

2.1 size of container

1: 1kg Φ15cm×7cm

2: 2.5kg Φ18cm×8cm

3: we will meet the special request . biggest sizeΦ20cm×13cm

2.2 maximum weight 5kg

2.3 precision ±0.1%

2.4 biggest vacuum -95KPa

2.5 biggest vacuum after nitrogen -40 KPa

2.6 printing 8 sets

2.7 packaging speed 12 sets./2.5kg can

10 sets./1kg can

2.8 air compression 0.6±0.05MPa

2.9 nitrogen purity 99.9% pressure ≥0.3Mpa

Contact Us

- HUPC Chemical Co., Ltd.

- Contact nameShirley Xia Chat Now

- Phone0086-571-88491745

- AddressFloor 3, Building 2, No.8 Xiyuan Three Road, Hangzhou, Zhejiang

Product Categories

New Products

-

Lampwork Rose Czech Grinding Glass Beads

-

Photoluminescent Pigment With Glowing Blue Green Color

-

Photoluminescent Pigment Luminescent Powder Pigment

-

Photoluminescent Powder Yellow Green

-

Blue Green Inorganic Photoluminescent Pigment

-

Luminescent Pigment Powder Pigments for Ceramic

-

Luminescent Pigment Blue Green Powder

-

Phtoluminescent Pigment Yellow Green

-

Photoluminescent Pigment Glow in the Dark Pigment

-

Blue Green Pigment And Powder Luminescent Powder

-

Luminescent Powder Pigment

-

Luminescent Powder Pigment Yellow Green

-

Glowing Pigment Yellow Green Photoluminescent Pigment for Plastic

-

Pigment Black 7-Carbon Black--Carbon Nanotubes Nanotube Carbon

-

Pigment Blue 29 Pigment Ultramarine Blue

-

Carbon Black Carbon Nanotubes Pigment Black 7 Carbon Nanotube

-

Flush Pigment of Pigment Black 7--carbon Black

-

Flush Pigment of Pigment Black 7 Carbon Black Carbon 7

Popular Searches

- flat tube

- test tube rack

- water bath oscillator

- lab quartz glass ware

- lab test tube

- borosilicate glass tube

- tube rack

- syringe filter

- test tube stopper

- test tube cap

- ps test tube

- tube holder rack

- round bottom test tube

- flat bottom test tube

- glass test tube with cork

- borosilicate glass test tube

- clear glass test tube

- laboratory test tube

- clear test tube

- borosilicate test tube

- sterile filter

- wooden test tube rack

- plastic test tube with cork

- plastic disposable test tube

- plastic test tube cap

- ps tube

- plastic tube stand

- pp tube rack

- lab rack

- tube box rack

Recommended Products

- NJbinglab High Purity PFA Reactor 1L, Ultra Low Leachability for Sensitive Chemical Processes

- Premium Quality Glass Test Tube Set for Laboratory Use

- Laboratory Glass Borosilicate Reagent Bottle 100ml-20000ml Glass Bottle With Blue Screw Cap

- 100ml TFM Digestion Liners Replacement for MARS EasyPrep Plus

- 100ml TFM Vessel Replacement for Milestone Part 34040

- Replacement of 110ml Digestion Vessels for MARSXpress Plus Rotors

- 50ml PFA Block Digestion Tubes

- Microwave Chemical Reactor

- Glass Reaction Kettle

- Double Layer Glass Reactor Series Products

- Laboratory Glassware Bottle Washer Automatic Bottle Cleaning Machine

- NJbinglab PFA Coil Tube, High Temperature Resistant

Find Similar Products By Category

- Instruments & Meters > Lab Utensil and Disposable > Test Tube

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Shirley Xia

Hi there! Welcome to my shop. Let me know if you have any questions.

Shirley Xia

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile