Welcome to the latest in precision technology engraving. The Portable Handheld Laser Marking Machine integrates the latest in fiber laser technology with ease of use, portability, and efficiency, fundamentally changing how we perceive laser marking machines. This device allows for precise and rapid laser marking on multiple materials, including metals and acrylics. This is useful to both businesses and enthusiasts. Learn more about this machine and how it can enhance operational capabilities while delivering stellar engraving results. Find more info now.

In this approach, a focused beam of light is used to change a material's surface. Due to the accuracy of laser engraver machines, they are often chosen for operations that require detailed marks or engravings. Their applications, however, go far beyond aesthetics as laser engravers also enhance compliance and traceability functions within various industries. Technicians using handheld laser engravers are able to achieve high quality and consistent results with little effort.

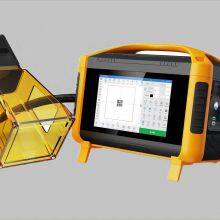

In general, portable laser marking devices have an easy-to-use interface, coupled with soft-touch controls and high-precision laser beams operated by fiber laser technology. To retain power while also being flexible and lightweight design, portable laser marking machines are crafted with advanced materials. Consequently, operators can utilize these handheld devices to engrave items into which conventional laser engraving machines cannot fit. Rather, the ergonomics of these devices allows engravers to carry out complex engravings easily and accurately.

Currently, all modern laser marking systems are based on fiber lasers. This is due to fiber laser technology’s unparalleled efficiency and beam quality. Compared to older methods like diode lasers and CO2 lasers, fiber lasers have a greater output power, size, and strength. these features alone make marking machines very attractive for high-speed laser operations with low maintenance requirements. Unlike other engravers, fiber laser engravers adapt to both non-metal and metal materials ensuring optimal performance. This level of flexibility is unmatched.

The various benefits provided by a portable handheld laser for engraving includes easy use, mobility, and affordability. These machines do away with heavier, stationary setups which tend to limit operational flow. The mobility of a laser marking machine fosters faster business operations and lower business costs due to the productivity of handheld engravers. Also, precision is guaranteed from the handheld laser marking system; every engraving is sharper and clearer than what the customer desires.

The true strength of portable handheld laser engravers lie in their ability to perform in multiple environments without compromising on quality. These machines allow operators to move from one task to the other with great precision, showcasing their efficiency. On-site laser marking tasks can now be done thanks to portable laser engravers, allowing businesses to significantly improve workflow efficiency. In an industrial setting, small spaces like workshops can greatly benefit from robust laser marking machines that do not take up much space while maximizing the usable area.

When looking to buy a portable laser engraving machine, it's essential to consider its features in terms of performance and usability. Leading machines on the market include sophisticated features such as adjustable beam power, internal cooling systems to prevent overheating, and intuitive control software. The leading laser engraving motion devices also protect the user and the materials being engraved which adds to the safety features of the machine. With regards to the quality of the engraving machines, portability, value, and solid construction high accuracy and long-term durability will be crucial, especially for meeting the rigorous and sustained demands in an industrial setting.

Marking metals is perhaps the most important function of engravers, and it is done with extreme precision and superior clarity. This type of engraving is highly critical to some industries like aerospace and automotive which involve a lot of metal parts. With precise high speed laser technology of a fiber laser engraver, deep engraving on hard materials like stainless steel and aluminum is possible. These machines are handy for serial numbering parts and providing long-lasting identification. Repair shops and parts suppliers require fiber markers because, unlike other lasers, fiber lasers are powerful enough to engrave hard materials like steel while maintaining engraving quality.

Dependable fiber laser markers can also perform well when working with materials like acrylic, plastic, and even glass. Fiber laser engraving machines can change with the properties of the material, which ensures all materials are worked on effectively no matter what they are made from. Fiber lasers are incredibly helpful for designers and manufacturers and that is because engraving acrylic often gives clean, smooth, and clear marks which improves the overall appearance through the smooth markings that are produced.

The main benefit of a handheld fiber laser is its versatility. This technology can be used in many fields such as the creation of jewelry and in the electronics industry. It is easy to switch from one material to another which is helpful for businesses that need to handle many projects because it means that the business does not need to purchase different pieces of equipment. Also, the simplicity of creating customized marks, whether elaborate designs or precise writing, is possible with fiber lasers.

Every purchase comes with its many considerations, especially when it involves technology, such as fiber laser marking machines. First and foremost, a customer-oriented business must put forth ample research on how to address a customer's needs first. Additionally, as customer service plays a major role in buying decisions, prospective buyers must also look into crane slings offered by whon the industry experts are. Looking into the completeness of a woven fabric, as well as the ease of operation, will set the benchmark for satisfaction.

Standing out from the crowd, light industrial tasks along with intricate engravings can be remarkably performed with utmost efficiency using 20W fiber lasers. Users should look into the software that comes along with the different models to ensure they’ll be able to get the best out of the machines accessibility and peed while executing engravings. Along with being competitively priced, each package comes with features that allow for enhanced precision for the multi-material approach.

For business-related tasks and personal projects, analyzing the specifics of laser engraving machines requires focusing on specifics of requirements. The most important features are adjusting laser power levels, working with both metals and non-metals, and the availability of different computer programs. High-performance engraving machines have additional smart protective systems, industrial grade construction, and engraver control panels that allow intuitive navigation. It is important to combine these factors so as not to sacrifice balance between the machine's effectiveness, robust construction, and ease of operation for the optimization of the user's effort.

Proper care for a handheld laser engraver enhances its functionality and durability. Lens cleaning and removing any built up debris is essential. Keeping the cooling systems functional, the software updated, and other systemic checks are crucial maintenance activities, too. Inspections performed regularly can mitigate issues before they become expensive repairs, optimizing the use of the engraver.

To maintain long-lasting effectiveness, portable lasers should be handled strictly per guidelines with regard to usage and maintenance. Accurate updates, addressing abnormalities quickly, and proper maintenance tools are all important. In turn, these optimized measures improve productivity while maintaining quality over extended periods of usage and wear. Focusing on supporting replacement parts and accessories also prolongs the lifespan of the laser marking machine, which helps reduce operational costs for businesses.

Troubleshooting marking lasers typically involves dealing with software problems, hardware issues, mechanical issues, and everything in between. Any marking laser has the potential for motion problems, range issues, misaligned laser beams, inconsistent intensity across writing surfaces, and overshooting during rapid movements. Fortunately lots of makers will have extensive guides on troubleshooting as well as customer service to assist with problems. Everyone involved in controlling the marking lasers should put in a minimum effort to improve continuity of operation.

A: Portable handheld laser engravers, especially those using fiber laser technology, are highly effective for metal marking. They can work on various metals such as stainless steel, aluminum, copper, and more. Fiber laser engravers are also suitable for some non-metal materials, though their primary strength is in metal laser applications.

A: Fiber laser engraver machines are generally more powerful and efficient than diode lasers, particularly for high speed laser marking on metals. Fiber lasers generate a smaller beam spot size and higher intensity, making them suitable for detailed engravings and cutting tasks. Diode lasers are more commonly used for less demanding applications.

A: Yes, many handheld laser marking machines can engrave cylindrical objects using a rotary attachment. This accessory allows the laser to maintain focus on curved surfaces, enabling consistent marking results on cylindrical items.

A: Mopa fiber lasers offer increased flexibility and control over engraving speed, pulse duration, and frequency, which can lead to finer, more detailed engravings. They are particularly useful for creating color engravings on stainless steel and achieving high contrast marks on anodized aluminum.

A: Yes, laser safety is a critical concern when operating any laser engraver. Proper protective equipment like safety goggles should be worn to prevent eye damage. Additionally, the working area should be well-ventilated, and the machine should be operated according to the manufacturer’s guidelines to ensure safety.

A: A touch screen interface makes the setup and operation of a handheld fiber laser engraver more intuitive and user-friendly. It allows operators to easily adjust settings, view previews of designs, and manage different projects directly from the device, enhancing overall efficiency.