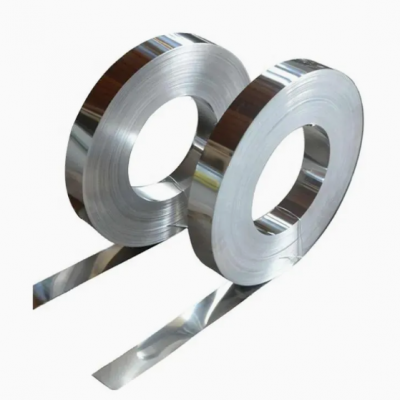

Customized Size Monel 404 Nickel Alloy Strip for Marine Fixtures

- Shanghai

- T/T L/C PayPal D/P Western Union Other

- 7 days

You May Like

-

Factory Warehouse Invar 36 Good Price Iron Feni36 Nickel Alloy 4j36 Bar Invar 36 Round Bar Per Kg

-

AMS 5759 L605 HS25 Gh605 Alloy L-605 R30605 Cobalt Nickel Alloy Bar

-

ASTM B444 Nickel Alloy Inconel 625 Pipe Price Per Kg in Evaporators

-

Nickel Alloy Tube Gh4033 Welded Tubing Post Weld Heat Treated Low Residual Stress High Cycle Fatigue Resistance for Aerospace Engineering

-

Alloy/Inconel/Angle/Magnesium/ Hastelloy/Nickel/Stainless Steel Inconel 718 N07718 5596 2.4668 Gh4169 Alloy Steel 8620 4140 Bars

-

Chloride-Resistant Hastelloy C22 Boiler Pipe - Factory Direct

Product Details

| Type | Nickel Strip | Purity | >98% | |

| Application | Aviation, Electronics, Industrial, Medical, Chemical | Standard | JIS, GB, DIN, BS, ASTM, AISI | |

| Powder | Not Powder | Alloy | Alloy |

Product Description

Single-phase solid solution Ni-Cu alloy Monel 404 Nickel Based Plate for Chemistry and petrochemical yield

| Super Alloy Monel 404

Specifications The following specifications cover Super Alloy Monel 404(tm)

Property Results Chemistry Data :

Aluminum 0.05 max Carbon 0.15 max Copper BalanceIron 0.5 max Manganese 0.1 max Nickel 52 - 57 Silicon 0.1 max Sulphur 0.024 max

Principal Design Features : This alloy of copper- nickel is another in the Monel family. It has excellent brazing capability and very low magnetic permeability. Applications : Used for capsules for transistors, ceramic-to-metal sealing. Machinability : Conventional machining techniques used for iron based alloys may be used. This alloy does work-harden during machining and has higher strength and "gumminess" not typical of steels. Heavy duty machining equipment and tooling should be used to minimize chatter or work-hardening of the alloy ahead of the cutting. Most any commercial coolant may be used in the machining operations. Water-base coolants are preferred for high speed operations such as turning, grinding, or milling. Heavy lubricants work best for drilling, tapping, broaching or boring. Turning: Carbide tools are recommended for turning with a continuous cut. High-speed steel tooling should be used for interrupted cuts and for smooth finishing to close tolerance. Tools should have a positive rake angle. Cutting speeds and feeds are in the following ranges: For High-Speed Steel Tools For Carbide Tooling Depth Surface Feed Depth Surface Feed of cut speed in inches of cut speed in inches inches feet/min. per rev. inches feet/min. per rev. 0.250" 60-70 0.030 0.250" 250-300 0.020 0.050" 90-100 0.010 0.050" 300-350 0.008 Drilling: Steady feed rates must be used to avoid work hardening due to dwelling of the drill on the metal. Rigid set-ups are essential with as short a stub drill as feasible. Conventional high-speed steel drills work well. Feeds vary from 0.0007 inch per rev. for holes of less than 1/16" diameter, 0.003 inch per rev. for 1/4" dia., to 0.010 inch per rev. for holes of 7/8"diameter. Surface speeds of 45-55 feet/minute, are best for drilling. Milling: To obtain good accuracy and a smooth finish it is essential to have rigid machines and fixtures and sharp cutting tools. High-speed steel cutters such as M-2 or M-10 work best with cutting speeds of 60 to 80 feet per minute and feed of 0.005"-0.008" per cutting tooth. Grinding: The alloy should be wet ground and aluminum oxide wheels or belts are preferred. Forming This alloy has good ductility and may be readily formed by all conventional methods. Because the alloy is stronger than regular steel it requires more powerful equipment to accomplish forming. Heavy-duty lubricants should be used during cold forming. It is essential to thoroughly clean the part of all traces of lubricant after forming as embrittlement of the alloy may occur at high temperatures if lubricant is left on. Welding The commonly used welding methods work well with this alloy. Matching alloy filler metal should be used. If matching alloy is not available then the nearest alloy richer in the essential chemistry (Ni, Co, Cr, Mo) should be used. All weld beads should be slightly convex. It is not necessary to use preheating. Surfaces to be welded must be clean and free from oil, paint or crayon marking. The cleaned area should extend at least 2" beyond either side of a welded joint. Gas-Tungsten Arc Welding: DC straight polarity (electrode negative) is recommended. Keep as short an arc length as possible and use care to keep the hot end of filler metal always within the protective atmosphere. Shielded Metal-Arc Welding: Electrodes should be kept in dry storage and if moisture has been picked up the electrodes should be baked at 600 F for one hour to insure dryness. Current settings vary from 50 amps for material 0.062" thick up to 190 amps for material of 1/2" and thicker. It is best to weave the the electrode slightly as this alloy weld metal does not tend to spread. Cleaning of slag is done with a wire brush (hand or powered). Complete removal of all slag is very important before successive weld passes and also after final welding. Gas Metal-Arc Welding: Reverse-polarity DC should be used and best results are obtained with the welding gun at 90 degrees to the joint. For Short-Circuiting-Transfer GMAW a typical voltage is 19-25 with a current of 100-175 amps and a wire feed of 225-400 inches per minute. For Spray-Transfer GMAW voltage of 26 to 33 and current in the range of 200-350 amps with wire feed rate of 200-500 inches per minute, depending on filler wire diameter. Submerged-Arc Welding: Matching filler metal, the same as for GMAW, should be used. DC current with either reverse or straight polarity may be used. Convex weld beads are preferred. Heat Treatment The alloy does not respond to heat treatment except for annealing after cold working. Forging No data. However the alloy is forgeable. Hot Working No data, but capable of being hot worked. Cold Working Cold forming may be done using standard tooling although plain carbon tool steels are not recommended for forming as they tend to produce galling. Soft die materials (bronze, zinc alloys, etc.) minimize galling and produce good finishes, but die life is somewhat short. For long production runs the alloy tool steels ( D-2, D-3) and high-speed steels (T-1, M-2, M-10) give good results especially if hard chromium plated to reduce galling. Tooling should be such as to allow for liberal clearances and radii. Heavy duty lubricants should be used to minimize galling in all forming operations. Bending of sheet or plate through 180 degrees is generally limited to a bend radius of 1 T for material up to 1/8" thick and 2 T for material thicker than 1/8". Annealing Anneal at 1400 F for 1 hour. Hardening Hardens due to cold working only. Physical Data : Density (lb / cu. in.)0.322 Specific Gravity8.86 Specific Heat (Btu/lb/Deg F - [32-212 Deg F])0.099 Electrical Resistivity (microhm-cm (at 68 Deg F))300 Melting Point (Deg F)2400 Thermal Conductivity146 Mean Coeff Thermal Expansion7.4 Magnetic Permeability1 Modulus of Elasticity Tension24.5

Mechanical Data : Form StripCondition Test Specimen AnnealedTemper 70Tensile Strength 65Yield Strength 23Elongation 45Rockwell B55 |

Contact Us

- Fuchuan Metal (Shanghai) Co., Ltd

- Contact nameGrace Chat Now

- AddressNo. 3389 Taihe West Road, Baoshan District

Product Categories

| Nickel Bars | Nickel Pipe | Nickel Plate |

New Products

-

Nickel Alloy Steel Seamless Pipe Incoloy N08825/2.4858 ASTM B423 for Oil & Gas

-

High Temperature Nickel Alloy Seamless Pipe DN 76x3 mm HN78T XH78T KHN78T TU 14-3-520-76

-

Inconel 725 (UNS N07725) Sheet/Plate Hastelloy C276/400, Incoloy 800/825, Monel 400 Nickel Alloy Supplier ASTM B168/B409 Certified

-

Durable N06625 Nickel Alloy Plate for Extreme Environments

-

N06600 Nickel Alloy Sheet - Durable and Corrosion-Resistant Material

-

High-Quality Nickel Based Inconel X-750 Sheet for Export

-

Premium Nickel Alloy Sheets - 1j79, 1j85, 4j29, 4j36 for Industrial Use

-

Inconel 625 & 625lcf (UNS N06625) Nickel Alloy Sheets & Plates High-Purity Grade for Aerospace & Chemical Processing

-

Premium Customized Nickel Alloy Magnetic Soft Plates for Industrial Applications

-

Incoloy 020 (UNS N08020) Sheet/Plate Excellent Corrosion Resistance Nickel Alloy 825, Inconel 600, Hastelloy C276 ASTM B409/B168 Certified

-

Age-Hardening Nickel Alloy Udimet 720 720li Gh4720li U720 U720li Nickel Alloy Plate Strip Sheet

-

Nickel Alloy Sheet N4 Huge Plates High Purity Nickel201 Pure Nickel Plate

Popular Searches

- stainless steel

- copper alloy

- copper pipe

- copper nickel alloy

- cu ni alloy

- molybdenum alloy

- nickel strip

- nickel plate

- nickel wire

- nickel sheet

- monel 400

- nickel bar

- nickel tube

- silver alloy

- c71500

- dental alloy

- nickel coil

- expansion alloy

- monel

- super alloy

- inconel 600

- based alloy

- based incoloy alloy

- based super alloy

- stainless steel

- alloy steel

- nickel plate

- steel coil

- monel 400

- steel coil strip

Recommended Products

- Factory Warehouse Invar 36 Good Price Iron Feni36 Nickel Alloy 4j36 Bar Invar 36 Round Bar Per Kg

- Nickel Alloy Sheet N4 Huge Plates High Purity Nickel201 Pure Nickel Plate

- Age-Hardening Nickel Alloy Udimet 720 720li Gh4720li U720 U720li Nickel Alloy Plate Strip Sheet

- Incoloy 020 (UNS N08020) Sheet/Plate Excellent Corrosion Resistance Nickel Alloy 825, Inconel 600, Hastelloy C276 ASTM B409/B168 Certified

- Premium Customized Nickel Alloy Magnetic Soft Plates for Industrial Applications

- Inconel 625 & 625lcf (UNS N06625) Nickel Alloy Sheets & Plates High-Purity Grade for Aerospace & Chemical Processing

- Premium Nickel Alloy Sheets - 1j79, 1j85, 4j29, 4j36 for Industrial Use

- High-Quality Nickel Based Inconel X-750 Sheet for Export

- N06600 Nickel Alloy Sheet - Durable and Corrosion-Resistant Material

- Durable N06625 Nickel Alloy Plate for Extreme Environments

- Inconel 725 (UNS N07725) Sheet/Plate Hastelloy C276/400, Incoloy 800/825, Monel 400 Nickel Alloy Supplier ASTM B168/B409 Certified

- High Temperature Nickel Alloy Seamless Pipe DN 76x3 mm HN78T XH78T KHN78T TU 14-3-520-76

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Non-ferrous Metal & Products > Nickel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Grace

Hi there! Welcome to my shop. Let me know if you have any questions.

Grace

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile