Product Description

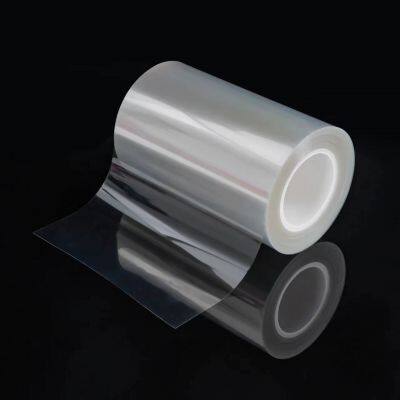

Transparent PET Release Film for PCB Lamination / Lamination Isolation Film / Se

Transparent PET Release Film is made of high-cleanliness PET base material coated with a special release layer. It offers excellent heat resistance (up to 190°C), low shrinkage, and good plasticity. The film surface is flat and uniform in thickness, with stable release force, making it suitable for FPC lamination, die-cutting, and adhesive lamination. It is easy to process, resistant to punching and tearing, available in various colors and flexible specifications, making it an ideal functional release material for the electronics and optoelectronics industries.

I. Application

The Transparent PET Release Film is mainly used for FPC lamination isolation, serving as an anti-sticking, isolation, and protective layer in high-temperature lamination processes. Its excellent heat resistance and dimensional stability ensure that the film remains smooth and wrinkle-free during lamination, maintaining product flatness and precision. In addition, it is widely used in:

Mobile phone accessories and electronic protective films

Adhesive products and die-cutting processes

Screen printing, pad printing, and label production

Medical and hygiene products

Nameplates, membrane switches, and flexible circuit boards

Insulating materials and laser anti-counterfeiting films

Reflective materials, waterproof membranes, graphite thermal conductive materials, and other fields

II. Features

Excellent Processability: The film is flat, with uniform thickness, not prone to wrinkles or breakage, suitable for high-speed die-cutting and automated lamination processes.

Easy Storage and Use: Long-term storage does not affect performance; smooth unwinding with stable tension control.

Stable High-Temperature Performance: Maintains good plasticity and low shrinkage even at 185°C, ensuring dimensional stability.

Outstanding Release Properties: Stable and adjustable release force; available in various levels from ultra-light to ultra-heavy to match different adhesive systems.

High Surface Cleanliness: Free from crystal points, impurities, or bubbles, ensuring no contamination in precision electronic and optical processing.

Impact and Tear Resistance: Excellent mechanical strength and abrasion resistance; suitable for repeated lamination and multiple peel processes.

Flexible Colors and Specifications: Available in transparent, white, blue, red, gold, black, and other colors, with customizable sizes and appearances.

III. Advantages SummaryHigh Temperature Resistance & Low Shrinkage: Maintains dimensional stability under high temperature; ideal for FPC and electronic lamination processes.

Stable and Controllable Release: Consistent release force ensures smooth lamination without adhesive residue.

Clean and Flawless Surface: Suitable for high-cleanliness applications in electronics, optics, and medical fields.

Multiple Custom Options: Thickness, color, release level, and surface treatment can all be customized.

Wide Range of Applications: Applicable across electronic materials, adhesive products, and industrial composites — one film, multiple uses.