Home > Products > Abrasive materials > (Cast Steel Shot/Alloy Steel Shot Abrasive Blasting) High-hardness Abrasive Material, Effective Improvement in Metal Rust Removal Efficiency.

(Cast Steel Shot/Alloy Steel Shot Abrasive Blasting) High-hardness Abrasive Material, Effective Improvement in Metal Rust Removal Efficiency.

- qingdao

- T/T

- 2 days

You May Like

-

Rust Removal Abrasive Cast Steel Shot/Alloy Steel Shot: Durable and Impact-Resistant - Long-Lasting Solution for Surface Treatment via Shot Blasting

-

Cast Steel Shot vs Traditional Abrasive: More Thorough Rust Removal, Reduced Consumption by 30%

-

Applicable to Shot Peening Machines and Sandblasting Chambers; a Complete Range of Models, Including S110-S930, Suitable for Various Equipment.

-

High-hardness, High-toughness Cast Steel Shot/alloy Steel Shot is the First Choice for Shot Blasting Rust Removal, Offering a Long Lifespan

-

Abrasive Blasting for Rust Removal Using Lotus Seed-shaped Abrasive Particles/cast Steel Abrasive Particles, Highly Durable and Efficient.

-

Abrasive Material for Rust Removal and Surface Grinding: High-hardness Cast Steel Sand/angled Steel Sand.

Product Details

| Shotblast Type | Shot Strengthen | Shotblast Material | Steel Shot | |

| Sandblasting Type | Automatic Sandblasting | Shotblast Application | Shipbuilding | |

| Sandblasting Method | Dry Spray | Sandblasting Applications | Metallurgy | |

| Transport Package | Tonne bag, ferry | Specification | S330 | |

| Trademark | Sheng Bo'an | Origin | Shandong Province |

Product Description

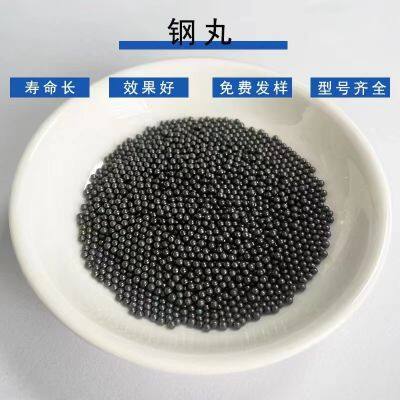

Abrasive material for rust removal, cast steel shot, alloy steel shot

Steel shot is a commonly used material for treating metal parts. The steel shot has a tight structure and uniform particle size. Treating the surface of metal parts with steel shot can increase the surface pressure of the metal parts, thereby greatly improving their fatigue resistance. The use of steel shot for surface treatment of metal parts has the advantage of fast cleaning speed. The steel shot and steel sand have appropriate hardness and good rebound properties. They can evenly and quickly clean corners and complex-shaped parts, thereby shortening the surface treatment time, improving work efficiency, and being a good material for surface treatment.

Steel shot is a commonly used surface treatment material, and there are numerous types of steel shot. The materials and equipment required also vary depending on the type of steel shot. Here are the main characteristics of steel shot:

Steel shot is a high-quality wear-resistant material. It has an appropriate hardness and strong toughness, with excellent impact resistance and a long service life. It exhibits excellent rebound properties, allowing for fast cleaning with low consumption. Steel shot has a wide range of applications, including the surface treatment of cast and forged parts, as well as parts after machining and heat treatment. Steel shot and steel sand are commonly used in various industries, such as general manufacturing and shipbuilding.

Contact Us

- Shan Dong Shengboan Metal Materials Co., Ltd.

- Contact namewang Chat Now

- AddressHuayi District Huixin Xianghe Courtyard, Jinan, Shandong

Product Categories

| Abrasive materials | Balancing material |

New Products

-

High-hardness Cast Steel Abrasive GH40 (0.7mm) Angular Steel Abrasive for Sandblasting, Polishing, and Rust Removal.

-

Cast Steel Sand/Wedge-Shaped Steel Sand Abrasive: Extremely High Hardness, Quick and Thorough Rust Removal Through Blasting!

-

Abrasive Material: Wire Cut Shot With a Length of Around 3.0 mm and a Diameter of 1.5 Mm.

-

Specification: 3-6mm Weighted Steel Shot, Compression Box Iron Shot, High Density, Uniform Particle Size

-

Specialist Supplier of Forged Iron Shot and Steel Shot, Available in Sizes 3-6mm, Ideal for Use in Weighting Boxes.

-

High-density Cast Steel or Iron Shot, Stable in the Hopper, Precise Weight Distribution.

-

Durable Cast Iron Shot/steel Shot - Ideal Material for Heavy Equipment Press Boxes and Engineering Counterweights.

-

Factory Direct Sale of Press Box Weighting Iron Pellets/steel Pellets, Complete Range of Specifications and Attractive Pricing.

-

High-density Weighting Material: Weighting Steel Sand, Iron Sand, Iron Powder.

-

High-density Weighting Steel Sand/iron Sand With a Density of 7.0 or Higher, Used for Mechanical Construction and Weighting Purposes.

-

High-density Weighting Material: Steel or Iron Sand With a Density of 6.5 or Higher; Stable Weighting, Reliable Quality.

-

High-density Weighting Steel Sand/iron Sand (density of 6.5 or Higher) – Ideal Material for Mechanical Base and Engineering Weighting Applications.

-

Cast Steel Shot S70-S930, Alloy Steel Shot, Complete Model Range, Excellent Quality, High Efficiency for Blast Cleaning and Rust Removal

-

For Rust Removal Using Sand Blasting, Choose Genuine Alloy Steel Shot for Faster Cleaning and a Significant Reduction in Sand Blasting Costs.

-

Cast Steel Shot S390/S280 Various Specifications Available in Stock, Ideal as Abrasive Material for Shot Blasting to Remove Rust and Grind Surfaces.

-

It's Not Just About Adding Weight; High-density Weighting Steel Shot/iron Shot Can Also be Used in Refractory Materials.

-

Cast Steel Shot/Alloy Steel Shot - Durable and Wear-resistant, Ideal for Long-lasting Shot Blasting Rust Removal.

-

Abrasive Material for Rust Removal, Cast Steel Shot, Alloy Steel Shot

-

Small-sized S170 (0.5mm) Sandblasting Abrasive Cast Steel Shot/alloy Steel Shot

-

Large-sized S780 (2.5mm) Alloy Steel Shot/cast Steel Shot for Blasting Rust Removal.

-

Cast Steel Shot/Alloy Steel Shot - Durable and Wear-resistant, Ideal for Long-lasting Shot Blasting Rust Removal.

-

Polishing and Rust Removal Abrasive, Cast Steel Shot S330 (1.0mm), Alloy Steel Shot, Produced by Shansheng'an Factory.

Popular Searches

- steel ball

- shot blasting

- ball bearing

- grinding media

- grinding ball

- steel sphere

- metal ball

- shot blasting machine

- shot peening

- stainless steel shot

- blasting

- metal abrasif

- peening

- steel cut wire shot

- steel grit

- hardness

- copper cut wire shot

- steel wire shot

- zinc cut wire shot

- cast steel shot

- carbon steel shot

- abrasive steel shot

- steel grit shot

- alloy steel shot

- steel ball

- shot blasting

- ball bearing

- grinding media

- grinding ball

- steel sphere

Recommended Products

- Cast Steel Shot S390/S280 Various Specifications Available in Stock, Ideal as Abrasive Material for Shot Blasting to Remove Rust and Grind Surfaces.

- Ceramic Bead Blasting B40 For Open Sandblasting Machine 3C Product 60-66% ZrO2

- For Rust Removal Using Sand Blasting, Choose Genuine Alloy Steel Shot for Faster Cleaning and a Significant Reduction in Sand Blasting Costs.

- Cast Steel Shot S70-S930, Alloy Steel Shot, Complete Model Range, Excellent Quality, High Efficiency for Blast Cleaning and Rust Removal

- Abrasive Material: Wire Cut Shot With a Length of Around 3.0 mm and a Diameter of 1.5 Mm.

- Cast Steel Sand/Wedge-Shaped Steel Sand Abrasive: Extremely High Hardness, Quick and Thorough Rust Removal Through Blasting!

- High-hardness Cast Steel Abrasive GH40 (0.7mm) Angular Steel Abrasive for Sandblasting, Polishing, and Rust Removal.

- Abrasive Material for Rust Removal and Surface Grinding: High-hardness Cast Steel Sand/angled Steel Sand.

- Abrasive Blasting for Rust Removal Using Lotus Seed-shaped Abrasive Particles/cast Steel Abrasive Particles, Highly Durable and Efficient.

- High-hardness, High-toughness Cast Steel Shot/alloy Steel Shot is the First Choice for Shot Blasting Rust Removal, Offering a Long Lifespan

- Applicable to Shot Peening Machines and Sandblasting Chambers; a Complete Range of Models, Including S110-S930, Suitable for Various Equipment.

- Cast Steel Shot vs Traditional Abrasive: More Thorough Rust Removal, Reduced Consumption by 30%

Find Similar Products By Category

- Tools & Hardware > Abrasive & Grinding > Blasting Media

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

wang

Hi there! Welcome to my shop. Let me know if you have any questions.

wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile