Home > Products > Stainless Steel Plate/Sheet/Strip > S31668 Stainless Steel Coil for Power Plants, 1.4547/316H, with High-Temperature Performance

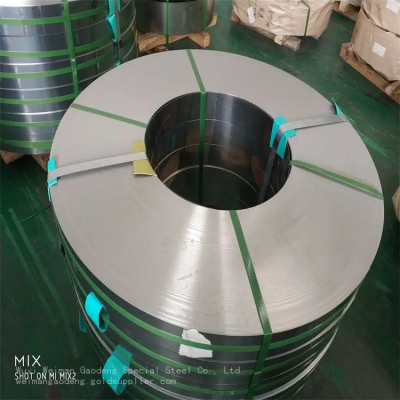

S31668 Stainless Steel Coil for Power Plants, 1.4547/316H, with High-Temperature Performance

- Shanghai

- T/T L/C

- 7 days

You May Like

-

SUS329J1 Stainless Steel Coil for Aerospace Components, S34778/F51, Offering Strength and Corrosion Resistance

-

F53 Stainless Steel Coil for Chemical Transport, 1.4529/2507, with Exceptional Corrosion Resistance

-

316Ti Stainless Steel Coil for High-Temperature Applications, F60/316L, in Harsh Environments

-

17-7PH Stainless Steel Coil for Pressure Vessel Manufacturing, S31803/304H, with High Toughness

-

316L Stainless Steel Coil for High-Pressure Equipment, 1.4529/347H, Offering Durability and Corrosion Resistance

-

17-4PH Stainless Steel Coil for Heavy Industry Machinery, F44/2205, with Superior Strength

Product Details

| Surface Treatment | Polished | Technique | Hot Rolled | |

| Standard | ASTM | Type | Stainless Steel Coils |

Product Description

Stainless steel plate, stainless steel sheet, stainless steel strip

Product Overview

The S31668 Stainless Steel Coil, also known as 1.4547/316H, is a high - quality product specifically designed for power plants. This stainless steel coil offers exceptional performance under high - temperature conditions, making it an ideal choice for various applications within the power generation industry.

Material and Surface Treatment

- Material Composition: The S31668 stainless steel coil is made of a carefully formulated alloy. It contains elements such as chromium, nickel, and molybdenum, which contribute to its excellent corrosion resistance and high - temperature stability. Chromium forms a passive oxide layer on the surface of the steel, protecting it from oxidation and corrosion. Nickel enhances the toughness and ductility of the material, while molybdenum further improves its resistance to pitting and crevice corrosion.

- Surface Treatment: The coil undergoes a polished surface treatment. This not only gives the coil a smooth and aesthetically pleasing appearance but also has practical benefits. A polished surface reduces the surface roughness, which can prevent the accumulation of dirt, debris, and corrosive substances. It also makes the coil easier to clean and maintain, ensuring its long - term performance in power plant environments.

Manufacturing Technique

The S31668 stainless steel coil is manufactured using the hot - rolled technique. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through a series of rollers to achieve the desired thickness and shape. This process offers several advantages:

- Improved Grain Structure: Hot rolling refines the grain structure of the steel, resulting in better mechanical properties. The refined grains enhance the strength and toughness of the coil, making it more resistant to deformation and cracking under high - stress conditions.

- Cost - Efficiency: Hot rolling is a relatively cost - effective manufacturing method compared to some other processes. It allows for the production of large - scale coils with consistent quality, which is essential for power plant projects that often require significant quantities of materials.

Standard Compliance

This stainless steel coil adheres to the ASTM standard. ASTM (American Society for Testing and Materials) standards are widely recognized and respected in the global market. By meeting ASTM standards, the S31668 stainless steel coil ensures:

- Quality Assurance: The coil has been tested and verified to meet specific requirements regarding its chemical composition, mechanical properties, and dimensional accuracy. This provides customers with confidence in the product's performance and reliability.

- Compatibility: It can be easily integrated into existing power plant systems and equipment that are also designed to comply with ASTM standards. This compatibility simplifies the installation and operation processes, reducing potential issues and costs.

High - Temperature Performance

One of the most significant features of the S31668 stainless steel coil is its high - temperature performance. In power plants, many components are exposed to extreme temperatures, and the ability of materials to withstand these conditions is crucial.

- Thermal Stability: The coil can maintain its mechanical properties at high temperatures. It has a high creep resistance, which means it can resist deformation over long periods of time under constant load and high - temperature conditions. This is essential for components such as boiler tubes and heat exchangers in power plants.

- Oxidation Resistance: At elevated temperatures, the coil forms a stable oxide layer on its surface, which protects it from further oxidation. This oxidation resistance ensures the long - term integrity of the coil, reducing the need for frequent replacements and maintenance.

Applications in Power Plants

The S31668 stainless steel coil has a wide range of applications in power plants:

- Boiler Systems: It can be used in boiler tubes, headers, and other components. The high - temperature performance and corrosion resistance of the coil make it suitable for withstanding the harsh conditions inside boilers, where it is exposed to high - pressure steam and hot combustion gases.

- Heat Exchangers: Heat exchangers are critical for transferring heat between different fluids in power plants. The S31668 coil's excellent thermal conductivity and corrosion resistance make it an ideal material for heat exchanger tubes, ensuring efficient heat transfer and long - term operation.

- Piping Systems: In power plant piping, the coil can be used to transport high - temperature and high - pressure fluids. Its strength and corrosion resistance prevent leaks and failures, ensuring the safe and reliable operation of the piping network.

Company - Backed Quality

This S31668 stainless steel coil is manufactured by a reputable company. With a history dating back to 2003, the company has evolved from an R & D - focused startup to a global special steel solution provider.

- Expert Team: The company has an expert leadership team and technical staff. The CEO, Mr. Sang Le, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. The Chief Metallurgist, Dr. Li Wei, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. The technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring the high - quality production and inspection of the stainless steel coil.

- Advanced Facilities and Services: The company has advanced processing and testing capabilities. It can perform radiographic testing (RT) and liquid penetrant testing (PT) on welded elbows and flanges. For the S31668 stainless steel coil, it also offers advanced NDT services such as Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT) for surface cracks, certified by SGS and BV. Additionally, the company provides custom - cutting services for plates and pipes, allowing customers to get the exact dimensions they need for their power plant projects.

In conclusion, the S31668 Stainless Steel Coil, 1.4547/316H, with its high - temperature performance, excellent material properties, and the backing of a reliable company, is an outstanding choice for power plant applications. It offers long - term reliability, cost - effectiveness, and compliance with international standards, making it a valuable asset for any power generation project.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

1.4460 Stainless Steel Coil for Marine Equipment, SUS631/F52, with Wear and Corrosion Resistance

-

2507 Stainless Steel Coil for Oil & Gas Pipelines, 316LMOD/316Ti, with Corrosion and Fatigue Resistance

-

F51 Stainless Steel Coil for Chemical Processing, S32950/316Ti, with Exceptional Mechanical Properties

-

316L Stainless Steel Coil for Electrical Equipment, F53/1.4547, Offering Heat Resistance and Durability

-

2507 Stainless Steel Coil for Structural Steel Construction, 31703/F44, with High Strength

-

347H Stainless Steel Coil for Thermal Energy Equipment, S31803/316H, with High-Temperature Resistance

-

304 Stainless Steel Round Bar Silver Tone 6mm Diameter Polished Surface Industrial Stainless Steel Rod

-

Silver Tone 304H Stainless Steel Round Bar 6mm Diameter Polished Industrial Stainless Steel Rod

-

6mm Diameter 316L Stainless Steel Round Bar Polished Surface Silver Tone Stainless Steel Rod

-

Polished Surface 316LN Stainless Steel Round Bar 6mm Diameter Silver Tone Industrial Rod

-

321 Stainless Steel Rod 6mm Diameter Polished Surface Silver Tone Stainless Steel Round Bar

-

309S Stainless Steel Round Bar Brushed Surface 8mm Diameter 1m Length Mechanical Stainless Steel Rod

-

Brushed Surface 310S Stainless Steel Round Bar 8mm Diameter 1m Length Mechanical Rod

-

8mm Diameter 347H Stainless Steel Round Bar Brushed Surface 1m Length Industrial Stainless Steel Bar

-

1m Length N08020 Stainless Steel Round Bar 8mm Diameter Brushed Surface Mechanical Stainless Steel Rod

-

Alloy 20 Stainless Steel Rod 8mm Diameter 1m Length Brushed Surface Stainless Steel Round Bar

-

N08367 Stainless Steel Round Bar Annealed Surface 10mm Diameter 2m Length Food Grade Bar

-

Annealed Surface N08800 Stainless Steel Round Bar 10mm Diameter 2m Length Food Grade Stainless Steel Rod

-

10mm Diameter 800 N08810 Stainless Steel Round Bar Annealed Surface 2m Length Food Grade Industrial Rod

-

2m Length 800H Stainless Steel Round Bar 10mm Diameter Annealed Surface Food Grade Stainless Steel Bar

-

N08811 Stainless Steel Bar 10mm Diameter 2m Length Annealed Surface Stainless Steel Round Bar

-

N08904 Stainless Steel Round Bar Polished Surface 12mm Diameter Corrosion Resistant Industrial Rod

-

Polished Surface 904L Stainless Steel Round Bar 12mm Diameter Corrosion Resistant Industrial Stainless Steel Bar

-

12mm Diameter N08926 Stainless Steel Round Bar Polished Surface Corrosion Resistant Mechanical Rod

Popular Searches

- steel sheet coil

- carbon steel coil

- stainless steel sheet

- steel strip

- stainless steel strip

- stainless steel plate

- steel plate

- steel sheet

- stainless steel coil

- stainless steel tube

- galvanized steel coil

- cold rolled stainless steel sheet

- steel coil strip

- steel sheet coil strip

- 304 stainless steel coil

- metal plate roll

- stainless steel circle

- 201 stainless steel

- crc

- cold rolled stainless steel strip

- 201 stainless steel coil

- stainless coil sheet

- cold rolled stainless steel plate

- cold rolled stainless steel rod

- building material

- stainless steel

- steel sheet coil

- galvanized steel

- carbon steel coil

- steel strip

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Stainless Steel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile