Home > Products > Stainless Steel > Light Weight SUS34778/S34779/304H/S30409 Stainless Steel Coils Custom Manufacturer for Aviation Interior Decoration

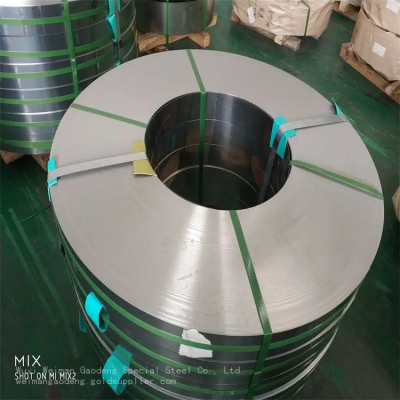

Light Weight SUS34778/S34779/304H/S30409 Stainless Steel Coils Custom Manufacturer for Aviation Interior Decoration

- Shanghai

- T/T L/C

- 7 days

You May Like

-

S321H/S32169/317L/S31703 High Gloss Stainless Steel Coils Factory Supply for Elevator Cabin and Door Panels

-

Wear Proof Stainless Steel Coils S25073/2507/1.4435/724L Factory Price for Conveyor Belt and Industrial Liners

-

Anti Corrosion 174PH/SUS630/F51/2205 Stainless Steel Coils Trusted Manufacturer for Chemical Tank Lining

-

Factory Direct Food Safe Stainless Steel Coils SUS631/177PH/S31803/F52 for Food Packaging and Can Making

-

Weather Resistant S32950/F53/2507/S32750 Stainless Steel Coils Manufacturer Supply for Solar Panel Frame and Support Structures

-

Stainless Steel Coils S32760/F55/F60/S32205 Marine Environment Suitable Factory Made for Ship Deck and Railings

Product Details

| Surface Treatment | Polished | Technique | Hot Rolled | |

| Standard | ASTM | Type | Stainless Steel Coils |

Product Description

Stainless steel plate, stainless steel sheet, stainless steel strip

Light Weight SUS34778/S34779/304H/S30409 Stainless Steel Coils for Aviation Interior Decoration

Product Overview

Our light - weight SUS34778/S34779/304H/S30409 stainless steel coils are specifically designed for aviation interior decoration. These coils are the result of advanced manufacturing processes and high - quality raw materials, offering a perfect combination of strength, durability, and aesthetic appeal for the demanding aviation industry.

Material Specifications

- Grade Varieties: We offer four different grades of stainless steel coils - SUS34778, S34779, 304H, and S30409. Each grade has its unique chemical composition and mechanical properties. For example, the 304H grade contains a higher carbon content compared to standard 304, which enhances its high - temperature strength. This makes it suitable for areas in the aircraft interior that may be exposed to relatively high temperatures.

- Surface Treatment: The coils undergo a polished surface treatment. This not only gives them a smooth and shiny appearance, which is essential for the aesthetic requirements of aviation interior decoration, but also provides better corrosion resistance. The polished surface is easy to clean, reducing the maintenance efforts in the aircraft.

- Technique: They are produced using the hot - rolled technique. Hot rolling allows for the shaping of the steel at high temperatures, which improves the ductility and formability of the coils. This is crucial for the complex shaping and bending operations required in aviation interior design, ensuring that the coils can be easily fabricated into various components.

- Standard: Our stainless steel coils comply with the ASTM standard. Meeting this international standard ensures that the products have consistent quality and performance, making them suitable for use in the global aviation market.

Key Features

- Light Weight: One of the most significant advantages of these coils is their light weight. In the aviation industry, weight reduction is of utmost importance as it directly impacts fuel efficiency. By using our light - weight stainless steel coils, aircraft manufacturers can reduce the overall weight of the interior components without sacrificing strength or durability.

- High Strength: Despite their light weight, the coils possess high strength. They can withstand the mechanical stresses and vibrations that occur during flight. This ensures the long - term reliability of the aviation interior components made from these coils.

- Corrosion Resistance: The stainless steel material provides excellent corrosion resistance. In the aviation environment, where the interior may be exposed to various chemicals, moisture, and other corrosive substances, this property is vital for maintaining the integrity and appearance of the components over time.

- Aesthetic Appeal: The polished surface finish gives the coils an elegant and modern look. They can be used to create a wide range of interior elements, such as panels, trims, and decorative features, enhancing the overall visual appeal of the aircraft cabin.

Customization Capabilities

As a custom manufacturer, we can meet the specific requirements of our customers in the aviation industry.

- Size and Thickness: We can produce stainless steel coils in various sizes and thicknesses. Whether you need a thin coil for delicate interior details or a thicker one for more structural components, we can customize the production according to your specifications.

- Shape and Design: Our advanced manufacturing facilities allow us to fabricate the coils into different shapes, such as curved panels or complex geometric forms. This flexibility enables the creation of unique and innovative aviation interior designs.

Manufacturing and Quality Assurance

Our company, with a history dating back to 2003, has evolved from an R & D - focused startup to a global special steel solution provider. We have a team of experts, including a CEO with over 20 years of experience in the special steel industry and a chief metallurgist with a PhD from Tsinghua University.

- Production Process: We operate automated production lines that cover the production of stainless steel coils. These lines ensure high - precision manufacturing and consistent quality. For example, we use 4000 - ton hydraulic presses for forging processes when necessary, which can produce components with high strength and accuracy.

- Quality Testing: We have advanced NDT (Non - Destructive Testing) services. Ultrasonic Testing (UT) to EN 10228 - 3 can detect internal defects as small as 0.5mm, and Magnetic Particle Testing (MT) can identify surface cracks. Our testing facilities are certified by SGS and BV, ensuring that every coil meets the highest quality standards before leaving the factory.

Applications in Aviation Interior Decoration

- Panels and Trims: The coils can be used to manufacture interior panels and trims. Their smooth surface and high - strength properties make them ideal for creating a clean and modern look in the aircraft cabin.

- Decorative Features: They can be fabricated into various decorative elements, such as handrails, light fixtures, and partition walls. The aesthetic appeal of the polished stainless steel adds a touch of luxury to the aviation interior.

- Structural Components: In some cases, the coils can also be used as structural components in the aircraft interior, where their high strength and light weight are beneficial for maintaining the overall structural integrity of the cabin.

Logistics and Delivery

We have strategically located warehouses in Wuxi, which allows us to ensure 48 - hour delivery to major Chinese ports. This rapid logistics service is crucial for meeting the tight production schedules of aircraft manufacturers. Whether you are in North America, South America, Europe, Asia, or other parts of the world, we can efficiently deliver our stainless steel coils to your doorstep, ensuring a seamless supply chain for your aviation interior decoration projects.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Factory Supply High Hardness Stainless Steel Coils SUS329J1/1.4460/254SMO/F44 for Tool Making and Molds

-

Low Temperature Resistant S31254/1.4547/XM19/S20910 Stainless Steel Coils Professional Manufacturer for Cryogenic Equipment

-

High Conductivity Stainless Steel Coils Gr660/SUH660/316Ti/S31668 Factory Direct for Heat Exchanger Plates

-

Manufacturer Supply Custom Width Stainless Steel Coils 1.4529/N08367/N08926/S31608 for Electrical Cabinet and Enclosures

-

China Supplier S31609/316H/347H/SUS34778 Anti Fingerprint Stainless Steel Coils Factory Price for Public Facility and Decoration

-

Food Processing Line Suitable Stainless Steel Coils SUS34779/304H/S30409/S321H Factory Supply for Conveyor and Chutes

-

Trusted Manufacturer Desalination Plant Applicable Stainless Steel Coils S32169/317L/S31703/S25073 for Membrane Housings

-

High Tensile Strength Stainless Steel Coils 2507/1.4435/724L/316LMOD Factory Made for Pressure Vessel Liners

-

Direct Factory Shipbuilding Industry Special Stainless Steel Coils 174PH/SUS631/2205/F51 for Hull and Fittings

-

Custom Manufacturer Renewable Energy Equipment Use Stainless Steel Coils SUS630/177PH/S31803/F53 for Wind Turbine Parts

-

F52/S32950/2507/S32750 Pharmaceutical Clean Room Suitable Stainless Steel Coils Factory Supply for Wall and Ceiling Panels

-

Factory Price Mining Equipment Liner Use Stainless Steel Coils S32760/F55/F60/S32205 for Ore Processing Machinery

-

Professional Manufacturer Aerospace Component Grade Stainless Steel Coils SUS329J1/254SMO/F44/S31254 for Aircraft Parts

-

1.4547/XM19/S20910/316Ti High Temperature Furnace Liner Suitable Stainless Steel Coils Factory Direct for Industrial Furnaces

-

Incoloy Alloy Bar Incoloy 925, N09925, Incoloy 800 for High-Temperature and Corrosion-Resistant Applications

-

High-Strength Incoloy Alloy Bar Incoloy 330, N08330, RA330 for Industrial Heat Treatment

-

Incoloy 800H Alloy Bar N08810, Incoloy 800HT for High-Temperature and Oxidation Resistance

-

Incoloy 825 Bar N08825, Incoloy926, N08926 for Corrosive Environments in Chemical Processing

-

Incoloy Alloy Bar Incoloy 901, IncoloyA-286, S66286 for High-Stress and Aerospace Applications

-

Incoloy 926 Bar N08926, Incoloy 800H for Marine and Chemical Industries With Superior Corrosion Resistance

-

Incoloy 945X, Incoloy 945, Incoloy 925 for Power Plant Equipment and Heavy-Duty Applications

-

Incoloy 800 Alloy Bar N08810, Incoloy 800HT for High-Temperature Furnace and Reactor Applications

-

Incoloy 803, Incoloy 907, Incoloy 909 Alloy Bar for Heat-Resistant Components in Gas Turbines

-

Incoloy 020, Incoloy 27-7MO, Incoloy 926 for Harsh Chemical and Marine Environments

Popular Searches

- building material

- steel sheet coil

- galvanized steel

- carbon steel coil

- stainless steel sheet

- steel strip

- stainless steel strip

- stainless steel plate

- steel plate

- steel sheet

- stainless steel pipe

- stainless steel tube

- austenitic stainless steel

- ppgi

- galvanized steel coil

- stainless steel ball valve

- cold rolled steel coil

- cold rolled stainless steel coil

- 304 stainless steel coil

- steel strip coil

- wire rod coil

- steel plate coil

- steel sheet plate coil

- hot rolled steel coil

- steel sheet coil

- carbon steel coil

- stainless steel sheet

- steel strip

- stainless steel strip

- stainless steel plate

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Stainless Steel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile