Home > Products > Insulated steel pipe > Steel jacket steel high-temperature prefabricated direct buried steam glass wool insulation and anti-corrosion steel pipe manufacturer

Steel jacket steel high-temperature prefabricated direct buried steam glass wool insulation and anti-corrosion steel pipe manufacturer

- Huanghua Port

- T/T

- 30 days

You May Like

-

Carbon steel flat weld flange diameter DN15--DN1000

-

Carbon steel welded seamless straight seam elbows

-

Carbon steel welded seamless elbow

-

Carbon steel stainless steel alloy steel welded flat weld neck butt weld flange

-

Carbon steel stainless steel alloy steel seamless straight seam elbow

-

Stainless steel, carbon steel, alloy steel, seamless straight seam welded elbow

Product Details

| Type | Seamless | Technique | Hot Rolled | |

| Surface Treatment | Black | Usage | Pipeline Transport | |

| Material | Carbon Steel | Section Shape | Round |

Product Description

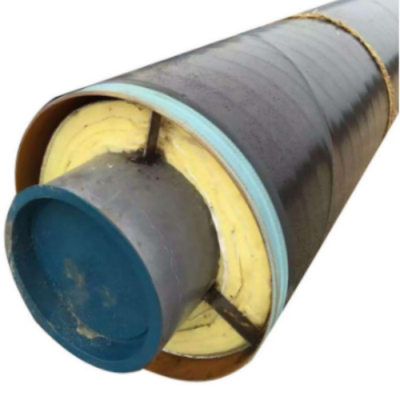

The steel jacket steel direct buried insulation pipe is composed of steel pipe, anti-corrosion coated pipe and ultra-fine glass wool filled with steel pipe and outer pipe is composed of graphite, calcium silicon tile and filled polyurethane foam. Steel jacket (steel jacket) burial technology is a new type of waterproof, leak-proof, anti-seepage, anti-compression, and fully sealed technology. Major breakthroughs have been made in the application of direct burial technology under high water level conditions.

The insulation form of steel jacket steel directly buried insulation pipe is different from manufacturer to manufacturer, and the following is an overview of the current insulation layer structure:

1. Composite insulation form

Due to the high medium temperature of the direct buried pipe, generally above 200 °C, the steam cannot be directly used as the polyurethane insulation layer of the buried heat pipe (because the carbonization temperature of polyurethane is about 142 degrees). Therefore, some manufacturers have adopted composite insulation structures, which can be divided into two structures: "plastic jacket steel" and "steel jacket steel".

1. "Plastic (FRP) steel" structure:

From the inside to the outside, there are working core pipes, lubrication layers, composite insulation layers, and high-density polyethylene (or FRP) outer protective layers. The function of the lubricating layer is to make the working core and the thermal insulation layer slide relative to avoid the interaction between the pipe working core and the inorganic insulation layer due to different coefficients of thermal expansion. Generally speaking, the lubricating layer material is inorganic lubricant or inorganic drag reduction layer, and the composite insulation layer is generally inorganic hydrophobic insulation material and polyurethane foam insulation layer. To further reduce heat loss caused by radiation, sometimes aluminum foil reflective layers are also applied to inorganic insulation. This kind of pipeline is usually suitable for low-temperature steam transportation below 220C, although the safety and service life are less than below, but the "steel jacket steel" structure of composite insulation pipes will be introduced, but the price is relatively low, so it is suitable for TH. The demand for steam conveying projects is low.

2. "Steel jacket" structure:

The structure is roughly the same as that of "plastic steel", from the inside to the outside, it is the working core pipe, the lubrication layer, the composite insulation layer (with aluminum foil reflective layer inside), and the steel outer guard pipe. This structure has a greater improvement than the former in terms of high temperature resistance, high pressure resistance, service life, and safety factor. Because the outer protective layer is a steel pipe, it can play a certain role in delaying the damage of leakage accidents in the operation of the inner pipe and preventing steam overflow and injury. The anti-corrosion of steel outer guard pipes generally adopts various forms such as two cloths and three oils, three layers of PE, FRP winding, polyurea spraying and epoxy powder coating. Merit:

1. Reduce the project cost

2. Anti-corrosion, good insulation performance and long service life.

3. Low heat loss and energy saving.

4. It occupies less land, fast construction, and is conducive to environmental protection.

5. Safety.

Apply:

Steel jacket steel direct buried insulation pipe is widely used in liquid and gas transportation pipeline network, chemical pipeline insulation engineering petroleum, chemical, central heating, air conditioning and ventilation pipelines, municipal engineering, etc

The insulation, sliding lubrication and waterproofing of the exposed pipe end of the insulation pipe with steel jacket steel. Insulation pipes not only have advanced technology and practical performance that are difficult to compare with traditional gutters and overhead pipelines, but also have significant social and economic benefits, and are also powerful measures for heating and energy saving.

Steel jacket steel insulation pipe, also known as "pipe within pipe", has a "two-step method", which is composed of high-density polyethylene outer protective layer, polyurethane rigid foam plastic pipe and steel pipe. One is a combination of steel pipes for conveying media, anti-corrosion jacket steel pipes, and ultra-fine glass wool filled between steel pipes and jacket steel pipes, or graphite, calcium silicon tiles and filled polyurethane foam. Steel casing (steel casing) burial technology is a new burial technology of waterproof, leak-proof, impermeable, compressive and fully enclosed, which is a major breakthrough in the use of direct burial laying technology in areas with high groundwater level.

Contact Us

- Hebei Intercontinental Heavy Industry Co., Ltd.

- Contact nameyinmingwang Chat Now

- AddressMengcun Hui Autonomous County Hope New District, Cangzhou, Hebei

Product Categories

| pipe fitting | flange |

Popular Searches

- copper tube

- Copper Ingot

- copper clad aluminum

- non-ferrous metal

- Copper Alloy

- hpmc

- micro fiber

- heater tube

- portland cement

- rapid hardening cement

- Hydroxypropyl Methyl Cellulose

- Copper Bars

- copper coil

- copper sheet

- copper rod

- brass rod

- brass copper

- copper pipe

- copper cathode

- Copper Round Bar

- Brass Bar

- Copper Flat Bar

- Copper Rod Bar

- Brass Round Bar

- Copper Ingots

- copper plate

- Brass Ingot

- Copper Pipes

- copper tubing

- copper bar

Recommended Products

- High Quality Seamless ASTM A312 Stainless Steel Pipe Polished pipes

- Seamless Stainless Steel Tube ASTM A312 316L 304/304L Stainless Steel Pipe

- Wholesale ASTM A312 3A 4 Inch 6 Inch 8 Inch Sanitary Welded Seamless Tube Stainless Steel Pipe

- ASTM A312 Seamless Smls Carbon CS Stainless Steel Ss Pipe

- Baotou Steel GB/T9948 10# 20# 15CrMo Petroleum Cracking Steel Pipes

- ASTM A312 Seamless/ Welded Stainless Steel Tube Round Pipe

- Baotou Steel NACE MR0175 ISO15156 Sour Service X52 PSL2 X60QS Seamless Steel Pipe

- China Enhanced Common Diameter 12inch Sch5s ASTM A312 Stainless Steel Seamless Plumbing Pipe Price List

- ASTM A312 Metal Tube Welded Stainless Steel Pipe Welding Tube Inoxidable Customized Pipe

- Industrial ASTM A312 Finish Stainless Steel Pipe

- ASTM A312 Tp347h Stainless Steel Seamless Pipe for Ethylene Cracking Furnaces with Third-Party Inspection

- Tp347 Tp347h ASTM A312 Stainless Steel Pipe/Tube Stainless Steel Round Pipe Ss Round Tube Seamless Steel Pipe

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Pipe & Tube

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

yinmingwang

Hi there! Welcome to my shop. Let me know if you have any questions.

yinmingwang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile