Home > Products > Nickel Alloy Plate, Sheet, and Strip > Cost-Effective Haynes 188 Strips for Heat-Resistant Components Manufacturing

Cost-Effective Haynes 188 Strips for Heat-Resistant Components Manufacturing

- Shanghai

- T/T L/C PayPal D/P Western Union Other

- 7 days

You May Like

-

New Design Heat Resistant Alloy for Industrial Applications Polishing Haynes 75 Coil/Strip

-

Haynes 263 Alloy/Haynes263/Uns N07263 Steel Sheet/Plate Factory Direct Supply

-

Chemical Sulfuric Acid Tank Use N08020 & Alloy20 Stainless Steel Bars, High Concentrated Acid Resistance, Solid Round Bar, Easy Welding, ASTM A479

-

Chemical Sulfuric Acid Tank Use N08020 & Alloy20 Stainless Steel Bars, High Concentrated Acid Resistance, Solid Round Bar, Easy Welding, ASTM A479

-

Marine Pile Foundation Use N08367 Stainless Steel Bars, Seawater Corrosion Resistance, Hexagonal Bar, Precision Cutting, ASTM A479

-

High-temperature Furnace Liner Use N08800 & 800 Stainless Steel Bars, 1000℃ Heat Resistance, Rectangular Bar, Millable, ASTM A479

Product Details

| Type | Nickel based precision alloy | Surface Treatment | Polishing | |

| Shape | Other, Customize according to the blueprint | Color | Silver |

Product Description

Nickel Alloy Plate, Sheet, and Strip

Introduction

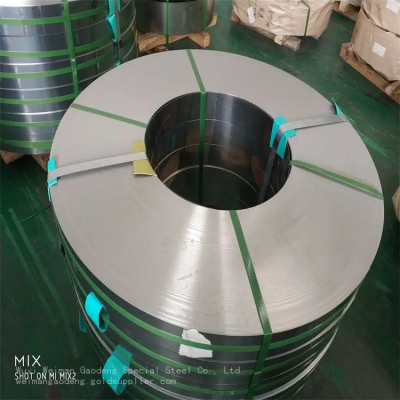

In the realm of high - performance materials for heat - resistant components manufacturing, our cost - effective Haynes 188 strips stand out as a top choice. Haynes 188 is a nickel - based precision alloy, renowned for its exceptional properties that make it suitable for a wide range of industrial applications.

Product Composition and Type

Our Haynes 188 strips are crafted from a nickel - based precision alloy. This alloy composition provides a unique combination of elements that contribute to its outstanding performance. Nickel serves as the base, offering excellent corrosion resistance and high - temperature stability. Along with nickel, other alloying elements are carefully added in specific proportions to enhance its mechanical and thermal properties. This nickel - based precision alloy is formulated to meet the stringent requirements of heat - resistant component manufacturing, ensuring reliability and durability in harsh operating conditions.

Surface Treatment

The surface of our Haynes 188 strips undergoes a meticulous polishing treatment. Polishing not only gives the strips a smooth and aesthetically pleasing silver appearance but also offers several functional benefits. A polished surface reduces friction, which is crucial in applications where the strips are in contact with other components. It also helps in preventing the accumulation of dirt and debris, which could potentially affect the performance of the heat - resistant components. Moreover, the polished surface enhances the corrosion resistance of the strips, as it provides a more uniform and less porous outer layer, protecting the underlying alloy from environmental factors.

Customization

One of the key advantages of our Haynes 188 strips is the ability to customize them according to the blueprint. We understand that different heat - resistant component manufacturing projects have unique requirements. Whether it's a specific shape, size, or dimensional tolerance, our experienced manufacturing team can work closely with you to produce strips that precisely match your design specifications. This customization option allows for greater flexibility in product development, enabling you to create heat - resistant components that are tailored to your exact needs. Whether you are working on a small - scale prototype or a large - scale production run, we can accommodate your customization requests.

Color and Aesthetic Appeal

The Haynes 188 strips come in a classic silver color. The silver hue not only gives the strips a modern and professional look but also has practical implications. Silver is a highly reflective color, which can help in dissipating heat to some extent. In heat - resistant component applications, this property can contribute to better thermal management. Additionally, the silver color is often associated with high - quality and durability, which can enhance the overall perception of your heat - resistant products in the market.

Performance in High - Temperature Environments

Our Haynes 188 strips exhibit remarkable performance in high - temperature environments. They can withstand extreme heat without significant loss of mechanical strength or deformation. This makes them ideal for use in heat - resistant components such as furnace linings, heat exchangers, and gas turbine parts. The alloy's high - temperature strength ensures that the components maintain their structural integrity even under prolonged exposure to elevated temperatures. It also has excellent oxidation resistance, which means that it can resist the formation of oxide layers on its surface at high temperatures, further extending the lifespan of the heat - resistant components.

Cost - Effectiveness

In today's competitive market, cost - effectiveness is a crucial factor. Our Haynes 188 strips offer an excellent balance between performance and cost. We have optimized our manufacturing processes to ensure efficient production, which allows us to offer these high - quality strips at a competitive price. By choosing our Haynes 188 strips, you can reduce your production costs without compromising on the quality and performance of your heat - resistant components. This cost - effectiveness makes our strips an attractive option for both large - scale manufacturers and small - to - medium - sized enterprises looking to enhance their product offerings.

Applications

The versatility of our Haynes 188 strips makes them suitable for a diverse range of applications in heat - resistant component manufacturing. In the aerospace industry, they can be used in engine components, where high - temperature resistance and mechanical strength are of utmost importance. In the power generation sector, they are ideal for heat exchangers and boiler parts. The chemical processing industry can also benefit from these strips in equipment that operates at high temperatures and is exposed to corrosive chemicals. Additionally, they can be used in the automotive industry for exhaust systems and other heat - related components.

Quality Assurance

We are committed to providing the highest quality Haynes 188 strips. Our manufacturing process adheres to strict quality control standards. Each batch of strips undergoes comprehensive testing to ensure that they meet or exceed the industry's performance requirements. We use advanced testing equipment and techniques to assess the mechanical properties, chemical composition, and surface quality of the strips. This rigorous quality assurance process guarantees that you receive Haynes 188 strips that are reliable, consistent, and of the highest quality for your heat - resistant component manufacturing needs.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Petrochemical Heater Tube Use N08810 & 800H Stainless Steel Bars, Creep Resistance, Anti-sulfur, Hollow Bar, Weldable, ASTM A479

-

Power Plant Heat Exchanger Use N08811 Stainless Steel Bars, High Thermal Conductivity, Flat Bar, Polished Surface, ASTM A479

-

Food Processing Mixer Use N08904 & 904L Stainless Steel Bars, Food-grade, Anti-organic Acid, Solid Square Bar, Smooth Surface, ASTM A479

-

Desalination Reverse Osmosis Use N08926 Stainless Steel Bars, Brine Resistance, Super Austenitic, Precision Bar, Cold Drawing, ASTM A479

-

Aerospace Fastener Use S20910 & XM-19 Stainless Steel Bars, High Tensile Strength, Small-diameter Bar, Threadable, ASTM A479

-

Medical Surgical Instrument Use S21800 Stainless Steel Bars, Biocompatible, High Hardness, Thin Bar, Grinding Process, ASTM A479

-

Commercial Building Railing Use S30400 & 304 Stainless Steel Bars, Rust Proof, Aesthetic, Polished Round Bar, Easy Installation, ASTM A479

-

Drinking Water Pipeline Use S30403 & 304L Stainless Steel Bars, Low Carbon, Non-magnetic, Seamless Bar, Cutting-to-length, ASTM A479

-

Ceramic Kiln Lining Use S30908 & 309S Stainless Steel Bars, High Temp Oxidation Proof, Wear-resistant, Solid Bar, CNC Machining, ASTM A479

-

N08020 Stainless Steel Round Bar, Hot Rolled With High Strength & Corrosion Resistant, Industrial Grade Alloy20 Stainless Steel Rod

-

Alloy20 Stainless Steel Rod, Polished Surface & Precision Size, Corrosion Resistant N08020 Stainless Steel Round Bar

-

N08367 Stainless Steel Round Bar, Cold Drawn & High Temperature Resistant, Industrial Grade Stainless Steel Rod for Engineering

-

N08800 Stainless Steel Rod, 800 Series With Polished Surface & High Toughness, Corrosion Resistant Stainless Steel Round Bar

-

800 Stainless Steel Round Bar, Hot Rolled & Precision Diameter 6mm-100mm, High Strength N08800 Stainless Steel Rod

-

N08810 Stainless Steel Rod, Cold Drawn & Corrosion Resistant, Industrial Grade 800H Alternative Stainless Steel Round Bar

-

800H Stainless Steel Round Bar, High Temperature Resistant & Polished Surface, Tough N08810 Stainless Steel Rod for Industry

-

N08811 Stainless Steel Rod, Hot Rolled & Precision Size, High Strength Stainless Steel Round Bar for Machinery Parts

-

N08904 Stainless Steel Round Bar, 904L Series With Polished Surface & Corrosion Resistant, Cold Drawn Stainless Steel Rod

-

Good Price Bright Surface N02201 Nickel Alloy Bright Rod

-

Best Price Uns N02200, N02201 Pure Nickel Sheet Alloy Sheet Nickel Plate

-

Pure Ni, Nickel Alloy 201, Uns N02201, 2.4061 Nickel Alloy Seamless Steel Pipe Tube for Anti-Corrossion Parts

-

Nickel 200 201 Uns N02200 N02201 Sheets Plates Nickel-based Alloy Pipe Manufacturer

-

ASTM N02200, N02201 99.9% Pure Nickel Plate Factory Manufacture Price

-

Nickel Alloy Steel Nickel 201 Alloy (UNS N02201) /2.4068 Seamless Pipe And Tube

Popular Searches

- stainless steel

- nickel strip

- stainless steel plate

- name plate

- steel plate

- steel sheet

- steel coil

- nickel sheet

- monel 400

- pure nickel

- steel sheet plate

- alloy steel plate

- cold rolled plate

- alloy sheet plate

- stainless plate

- nickel alloy sheet

- copper alloy plate

- nickel coil

- nickel alloy tube

- surface plate

- incoloy 800

- hastelloy plate

- rolling plate

- nickel alloy coil

- nickel belt

- nickel alloy strip

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Alloy > Nickel Alloy

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile