Home > Products > CFA Auger Drill Pipe > Coal Mining Machinery Parts Geological Spiral Drill Rod Drill Pipe

Coal Mining Machinery Parts Geological Spiral Drill Rod Drill Pipe

- China

- T/T L/C PayPal D/P Western Union

- 7 days

You May Like

-

All Kinds of Models Cfa Drilling Rig Use Drilling Bit Pipe Hammer with Best Price

-

Durable and High Efficiency Auger Drill Pipe for Drilling Hole

-

High Efficiency Spiral Drill Rod Hollow Stem Auger for Geological Drilling

-

Hot Selling Custom Length Auger Spiral Drill Pipe for Coal Mine Exploration Casting Processing Drill Tool

-

Cfa Continuous Auger Flight Auger Rod

-

High Efficiency Spiral Hollow Stem Continous Cfa Auger Rod

Product Details

| Condition | New | Application | Other, Construction machinery parts | |

| Type | Other, CFA Rotary Drilling Rig |

Product Description

Robot welding

Product Overview

The Coal Mining Machinery Parts Geological Spiral Drill Rod Drill Pipe is a high - performance and essential component in the coal mining and geological exploration industries. Engineered with precision, this drill pipe is designed to meet the rigorous demands of extracting coal and conducting geological surveys. It is brand - new, ensuring that users receive a product with the highest quality and reliability right from the start.

Design and Structure

- Spiral Design: The most prominent feature of this drill rod is its spiral shape. The spiral design serves multiple purposes. Firstly, it helps in efficient cuttings removal. As the drill bit penetrates the coal seam or geological formations, the spiral channels on the drill rod allow the cuttings to be carried upwards and out of the borehole. This reduces the risk of cuttings accumulation, which can cause drill bit jamming and slow down the drilling process. Secondly, the spiral design also provides additional strength and stability to the drill rod, enabling it to withstand high - torque forces during drilling.

- Robust Construction: The drill pipe is made from high - quality steel materials. These materials are carefully selected for their excellent mechanical properties, such as high tensile strength and good wear resistance. The outer surface of the drill rod is treated with a special coating to enhance its corrosion resistance, making it suitable for use in various harsh mining environments, including wet and acidic conditions.

- Precision Threads: The drill rod is equipped with precision - machined threads at both ends. These threads ensure a secure and tight connection between different sections of the drill rod. The accurate threading also allows for quick and easy assembly and disassembly of the drill rod, which is crucial for reducing downtime during drilling operations.

Performance and Efficiency

- High Penetration Rate: Thanks to its optimized design and high - quality materials, this drill rod can achieve a high penetration rate. It can quickly and effectively penetrate through different types of coal seams and geological formations, including hard rock layers. This high penetration rate significantly improves the overall efficiency of coal mining and geological exploration projects, reducing the time and cost required for drilling.

- Low Energy Consumption: The drill rod is designed to minimize energy consumption during drilling. The smooth spiral surface and efficient cuttings removal system reduce the frictional resistance between the drill rod and the surrounding rock or coal. As a result, less power is required to drive the drill rod, leading to lower energy costs for the users.

Compatibility

- Versatile Compatibility: This geological spiral drill rod drill pipe is highly compatible with a wide range of coal mining machinery and drilling equipment. It can be used with different types of drill rigs, including rotary drill rigs and percussive drill rigs. Whether it is a small - scale coal mining operation or a large - scale geological exploration project, this drill rod can be easily integrated into the existing equipment, providing users with a flexible and cost - effective solution.

- Interchangeable Parts: The drill rod is designed with interchangeable parts, which means that users can easily replace damaged or worn - out parts without having to replace the entire drill rod. This not only reduces the maintenance cost but also ensures the continuous operation of the drilling equipment.

Safety Features

- Anti - Vibration Design: During the drilling process, vibrations can cause damage to the drill rod and the drilling equipment, as well as pose a safety risk to the operators. This drill rod is equipped with an anti - vibration design, which effectively reduces the vibrations generated during drilling. By minimizing vibrations, the drill rod extends the service life of the equipment and improves the safety of the operators.

- Load - Bearing Capacity: The drill rod has a high load - bearing capacity, which means it can safely carry the weight of the drill bit and other attached equipment during drilling. This high load - bearing capacity ensures the stability of the drilling operation and reduces the risk of drill rod breakage, which could lead to serious accidents in the mining or exploration site.

In summary, the Coal Mining Machinery Parts Geological Spiral Drill Rod Drill Pipe is a top - quality product that offers excellent performance, high efficiency, wide compatibility, and reliable safety features. It is an ideal choice for coal mining companies and geological exploration organizations looking to enhance their drilling operations.

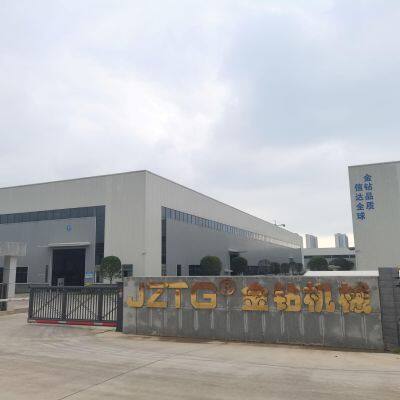

Company Profile

Changsha Mingyi Machinery Equipment Co.,Ltd pecialized in pile driving solutions with our own production base , with over 33600 square meters and annual ouput of 5,000 unites. Our factory locates in Hunan province which is in the center of China famous for heavy equipment manufacturers. MINGYI is committed to manufacture and supply most reliable and highest cost-performance products for piling works including Kelly Bars, Drilling Tools, Drilling teeth, Double and Single Wall Casing, Roller Bits, ect . We are keep 300-400 pieces in stock to ensure quiclky delivery. Our production process utilized advanced equipment,inlcuding 30kw laser cutting machines , high-power shot blasting machine ,beveling machine, and a complete assembly line with riveting tools ,we also employ professional pain boothss and automated welding robot syssterms to ensure every drilling bucket meets the highesst standards of quality and durability . our professional team is ready to support you with customizable designs and excellent after-sales service!

Contact Us

- Changsha Mingyi Machinery Equipment Co., Ltd.

- Contact namezhu Chat Now

- Address1917, Building 18, Contemporary Square, No. 288 Kaiyuan East Road, Xingsha Street, Changsha County, Changsha, Hunan

Product Categories

| Auger Bit | CFA Auger Drill Pipe | Core Barrel | Drilling Bucket |

| Kelly Bar | Spare Part | Drill Rig Swivel | Belling Bucket |

New Products

-

Auger Drill Rod Twist Dril Rod for Mine Drill Rig

-

China Factory Price High Speed Auger Drill Rod/spiral/pipe/single Thread and Thread Twist Drill Rod for Coal Mining

-

Excavator Hydraulic Auger Torque Earth Auger Drill Post Hole Digger Auger for Sale

-

CFA Auger Earth Drill Machine Soli Long Auger Construction Machinary Parts for Bored Pile Foundation

-

CFA Large-Scale Rotary Drilling Rig Construction Machinery Part for Infrastructure Projects

-

Construction Piling Tools 20 Meters Long Straight Soil Earth Auger for Foundation Drilling Construction

-

Rotary Drilling Tools Cylindrical Bucket Core Barrel for Coring Rock

-

Construction drilling tools Core Barrel with Bullet Teeth for all kinds of rotary drilling rig

-

Foundation Engineering Construction Core Barrel Bullet Teeth Rock Bucket for Rotary Drill Rig Construction Machinery Part

-

Drilling Tools Bored Piling Drilling Bucket Equipment Cleaning Bucket Drill for Construction

-

High-Strength Interlocking Kelly Bar for Casagrande Drilling Equipment

-

High Strength Wear-Resisting Alloy Steel Interlocking Friction Kelly Bar

-

High-Strength Interlocking Hydraulic Square Kelly Bar for Reliable Performance

-

Rotary Digging/Drilling Machine/Piling Rig Spare Parts Kelly Bar

-

Factory Rotary Drilling Rig Accessories for Building and Bridge Foundation Kelly Bar

-

High-Strength Alloy Steel Kelly Bar for Rotary Drilling Rig with CE Certification

-

Construction Engineering Borehole Pile Rotary Drilling Rig Kelly Bar for Soil Rock Drilling with High Precision

-

Kelly Bar Rotary Drilling Tool Manufacturer Drilling and Piling Tools

-

Construction Kelly Bar for Rotary Drilling Rig Interlocking/Friction

-

Customizable All-Brand Multi-Lock Kelly Bar of New Condition Rotary Drilling Rig Equipment Accessory

-

Locking Kelly Bar of Rotary Drilling Rig for Building Construction Pile Foundation Engineering Interlocking Kelly Bar / Frictional Kelly Bar

-

China Rotary Drilling Interlock Kelly Inter-Locking Kelly Bar for Rotary Drilling

-

Customize All Brand Drilling Rotary Rig Spring for Kelly Bar

-

Rotary Drilling Rig Construction Machinery Part Interlocking Kelly Bar

Popular Searches

- cutting tool

- rock drill

- drilling machine

- drilling tool

- hole digger

- earth auger

- ground drill

- flight

- earth drill

- gasoline earth auger

- soil auger

- rock auger

- ice auger

- hole digger auger

- earth auger drill

- drilling machine auger

- auger drill bit

- hydraulic auger

- drilling bucket auger

- auger bit

- post hole

- rock drilling auger

- excavator auger

- hammer drill

- rock drill

- dth hammer

- drilling machine

- drilling equipment

- drill tool

- drilling tool

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Engineering & Construction Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhu

Hi there! Welcome to my shop. Let me know if you have any questions.

zhu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile