Home > Products > Steel coil sheet and plate > S32750/2507 Duplex Steel Stainless Steel Strip From China

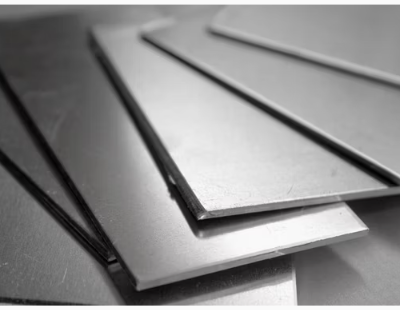

S32750/2507 Duplex Steel Stainless Steel Strip From China

- 0 Kilogram / Kilograms per Month

- T/T L/C PayPal D/P Western Union Other

- 8 days

You May Like

-

ASTM AISI Ba 2b 201 304 Cold Rolled Stainless Steel Pipe

-

ASTM Smooth Surface O H12 H14 H16 H18 H22 H24 Heat-Resistant and Corrosion-Resistant Composite 1050 1100 3003 3105 5052 7075 8011 Aluminum Alloy Plate

-

Alloy Aluminum 2A16 Corrosion Resistant Bright Surface Aluminium Plate

-

Ba PPGI Roofing Sheet 8K/N0.1 410 Cold Rolled/Mirror Zinc Color Coated Aluminum Galvanized Stainless Steel Strip Coil for Building Material

-

2b Ba No. 1 No. 4 Finished 304 410 430 Rolled Stainless Steel Coil Factory Fob Price

-

253mA Heat Resistant Stainless Steel Alloy Corrosion Resistant Plate

Product Details

| Type | Stainless Steel Bars | Certification | ISO, ROHS, IBR, AISI, ASTM, GB, EN, DIN, JIS, Other | |

| Shape | Round | Grade | Other | |

| Technique | Other | Surface Treatment | Polished | |

| Standard | ASTM, AISI, GB, JIS, DIN, EN, Other | Specification | OEM | |

| Trademark | ZHONGZHENG INTERNATIONAL | Origin | China |

Product Description

stainless steel roll

| ASTM Specification | ASTM A240 / ASME SA240 |

| Standard | MSRR, AMS, BS, ASTM A240 / ASME SA240 |

| Length& Sizes Duplex 2507 board | 1000 mm x 2000 mm, 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm, 2m, 2.44m, 3m, 36″ X 120″ or 48″ X 144″, 4′ x 8′, Cut to size available |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Hardness Duplex 2507 board | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Temper | Annealed |

| Condition | Polished on both sides |

| Finish Duplex 2507 board | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Stock in form of Duplex 2507 board | Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Dealers & Distributor of | ATI, POSCO, JISCO, TISCO, LISCO, BAOSTEELESSAR, JINDAL, BHUSHAN, IMPORTED material |

| Test Report Duplex 2507 board | Raw Materials Certificate |

| EN 10204/3.1B | |

| 100% Radiography Test Report | |

| High special strength, high melt point | |

| Third Party Inspection Report, etc | |

| Excellent corrosive resistance, good thermal resistance | |

| Customer support after-sales service | |

| Strict Control from Raw Material to Finished | |

| Profiling Duplex 2507 board | To provide a full profiling service we use numerous profiling methods including: |

| Plasma Plate Cutting | |

| Laser Plate Cutting | |

| Oxy-propane Flame Cutting | |

| Specialized in Duplex 2507 board | material under 3/16 " [5.00 mm] in thickness and 24″ [600 mm] and over in width |

| material 3/16″ [5.00 mm] and over in thickness and over 10″ [250 mm] in width | |

| cold-rolled material under 3/16″ [5.00 mm] in thickness and under 24″ [600 mm] in width | |

| Free Quote, Inquiry answered within 24 hours | |

| We offer a comprehensive services designed to add value to your project: plasma cutting, waterjet cutting, laser cutting, bending and mechanical processing, edge preparation, welding, sawing and shearing. | |

The 2507 stainless steel plate is engineered for maximum resilience against pitting corrosion, boasting a PREN value of up to 43. Its superior corrosion resistance extends to stress corrosion cracking (SCC), crevice corrosion, and general corrosion. These combined properties make the duplex 2507 an incredibly versatile and reliable choice for demanding environments.

With a yield strength that is twice that of the 300 series stainless steel, 2507 stainless steel allows for the use of thinner sections under similar load conditions, effectively reducing material costs.

Boasting yield and tensile strengths double that of traditional stainless steel, 2507 significantly enhances wear resistance.

Desalination processes.

Equipment for the oil and gas industry, including offshore platforms, pipelines, and well casings.

Chemical processing equipment, ideal for handling corrosive substances.

Pulp and paper industry applications, especially bleaching process equipment.

Petrochemical industry applications, including PVC strippers.

Water desalination facilities.

Power industry systems, such as flue gas desulfurization (FGD) units.

Marine components, such as ship propellers and shafts.

Pollution control equipment like scrubbers.

Fittings are vital for connecting and directing fluid flow in pipelines and systems, including elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples.

Surface Description of Stainless Steel Plate

| Finish Designation | Method and degree of finish |

| No.1 | After hot rolling, heat treatment, pickling or other equivalent treatment is applied. |

| No.2D | Annealing and pickling are performed after cold rolling; material is soft with surface of silver-white luster; used for general applications and deep drawing. |

| No.2B | After 2D finish, skin pass rolling is performed to obtain a more suitable luster; the surface becomes very exquisite; used for general applications. |

| No.3 | Intermediate 100-120 grit finish; used for applications in which surface polishing is performed after shaping. |

| No.4 | General 150-180 grit finish; used for restaurants and kitchen equipment and tools. |

| #240 | 240 grit finish; used when a finer finish than No. 4 is required; typically for restaurants and kitchen equipment and tools. |

| #320 | 320 grit finish polished product. |

| HL | This finish is performed by continuous linear polishing using an abrasive of appropriate grain size; mainly used for architectural applications. |

| BA | Achieved by performing bright annealing after cold rolling and then skin pass rolling to obtain even greater reflectance; provides excellent corrosion resistance; used for household appliances, kitchen equipment, and automobiles. |

| 8K | Through multiple grinding, it achieves very high brightness and smoothness, like a mirror. |

Zhongzheng International embarked on its illustrious stainless steel journey in 2003. With over two decades of dynamic growth and groundbreaking innovation, it has risen to the pinnacle of the industry, firmly establishing its esteemed reputation in stainless steel materials and advanced processing.

With an illustrious history in international business, Zhongzheng's 2023 export revenue surged past US$100 million. By strategically establishing three export service bases in China, the company has forged robust alliances with engineering firms, steel mills, and global trading entities. This extensive collaborative network continually enhances service capabilities and ambitiously expands Zhongzheng's footprint in overseas markets.

Comprehensive Stainless Steel Plate ServiceZhongzheng International redefines stainless steel services with its innovative 'supermarket' model, partnering globally with renowned steel mills. With an impressive inventory of 160,000 tons-comprising 20,000 tons of diverse metals, including ordinary stainless steel plates, duplex steel plates, nickel-based alloy plates, and heat-resistant steel plates-Zhongzheng ensures reliability, unparalleled quality, and strict adherence to specifications and delivery standards.

Advanced Processing CapabilitiesEquipped with cutting-edge steel processing equipment and professional testing centers, Zhongzheng excels in cutting, grinding, forming, beveling, welding, heat treatment, machining, spraying, and beyond. Serving over 30 diverse industries-including automotive, home appliances, elevators, new energy, vacuum semiconductors, food and beverage/biofermentation, petrochemicals, and energy equipment-Zhongzheng's expertise is unrivaled.

Diverse and Reliable ServicesZhongzheng's extensive service experience is reflected in its wide range of offerings. With a client base exceeding 70,000 across 30 industries and 30,000+ active customers, Daxun's industry recognition and service excellence are well-established.

Efficient and High-QualityZhongzheng guarantees prompt and efficient delivery of stainless steel products through an integrated system that merges information flow, logistics, and capital flow. Real-time order data seamlessly links to the logistics system, ensuring swift delivery. Strategically positioned processing centers near highways, rivers, and oceans facilitate efficient scheduling, rapid response, and smooth transportation.

Quality CommitmentDedicated to quality and integrity, Zhongzheng introduces 'Performance Excellence Management' and adopts 'PDCA+Lean' management principles, ensuring 'Zhongzheng = assured quality' becomes synonymous with trust. The implementation of a sophisticated ERP system allows full traceability of each steel plate, reinforcing the industry's anti-counterfeiting efforts.

Save Costs for CustomersZhongzheng prioritizes time, material, and stress savings for customers, ultimately reducing costs. By offering cost-optimized material recommendations and streamlined processing services, Zhongzheng enhances material utilization. Continuous lean improvement activities enable Daxun to minimize its own costs and pass on savings to customers. Additionally, a comprehensive product traceability system and prompt resolution of quality concerns provide customers with unparalleled peace of mind.

| Name | 2507/S32750 |

| UNS | S32750; S39275 |

| En No. | 1.441 |

| C (max.) | 0.03 |

| Mn | 1.2 |

| Si | 0.8 |

| Cr | 24.0-26.0 |

| Ni | 6.0-8.0 |

| Mo | 3.0-5.0 |

| N | 0.24-0.32 |

| Cu | 0.5 |

| Other | S 0.020 max; P 0.035 max |

| PREN | 40-43 |

| Grade | Property | Value |

| 2507/ S32750 | Density (g/cm3) | 7.8 |

| 0.2% Offset Yield Strength | 80 ksi | |

| Ultimate Tensile Strength | 116 ksi | |

| 0.1% Offset Yield Strength 0.2% | 91 ksi | |

| Elongation in 2 inches, % | 15% | |

| Hardness Rockwell C | 32 | |

| Impact Energy | 74 ft.-lbs | |

| Density | 0.28 lb per inch3 | |

| Modulus of elasticity | 28 x 10(6) psi | |

| Coefficient of thermal expansion | 7.2 x 10(-6) per of at 68 to 212 of | |

| Thermal conductivity | 8.7 Btu/hr ftoF | |

| Heat capacity | 0.12 Btu/ lb oF | |

| Electrical resistivity | 31.5 x10(-6) ohm-inch |

| Grade | Type | Thickness | Surface |

| Austenitic | 304/304H/304L/304J1 | 0.25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0.4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0.3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ultra Pure Ferrite | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B,2D | |

| 409L | 0.4-2.5mm | 2B,2D | |

| Grade | Type | Thickness | Original |

| Heat-resistant Steel | 309S | 0.5-40mm | CHN |

| 310S | 0.5-40mm | CHN | |

| Duplex Steel | 2101 | 1.5-50mm | CHN |

| 2304 | 3.0-50mm | CHN | |

| 2205 | 0.5-60mm | CHN | |

| 2507 | 1.0-60mm | SWE / JPN / CHN | |

| Super Austenitic Steel | N08904 | 0.6-50mm | SWE / JPN / CHN |

| S31254 | 0.5-50mm | SWE / JPN / CHN | |

| N08926 | 0.5-50mm | SWE / JPN / CHN | |

| N08367 | 0.5-50mm | SWE / JPN / CHN | |

| Nickel Base Alloy | N08031 | 1.0-50mm | US / JPN / GER |

| N08810/N08800 | 0.8-50mm | US / JPN / CHN | |

| N08028 | 1.0-20mm | US / GER / JPN | |

| N08020 | 1.0-20mm | US / GER / JPN | |

| N08825 | 0.8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0.5-50mm | US / GER / JPN | |

| N06022 | 1.0-50mm | US / GER / JPN | |

| N06625 | 0.8-20mm | US / GER / CHN | |

| N04400 | 1.0-20mm | US / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0.5-20mm | US / JPN | |

| Titanium | TA1/Gr1 | 0.5-50mm | JPN / CHN |

| TA2/Gr2 | 0.5-50mm | JPN / CHN | |

| Welding Material | ERNiCrMo-13 | 1.2,2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | US |

A: We offer a diverse range of general steel types such as 310S, 316L, 304, 304L, 201, 904L, 316H, 316, 316L, and 300 series.

Additionally, we provide 400 series and duplex stainless steel like 2205, 2304, 2101, 2507, and high-nickel alloys including 904L, 800H, and 600H.

Q2. Can you produce the products according to my own drawings?

A: Absolutely, we can manufacture products based on your provided drawings to ensure they meet your exact specifications.

Q3. How does your factory do regarding quality control?

A: Quality is our top priority. We place significant emphasis on meticulous quality control from the start of production to its completion.

Q4. Can I request to change the form of packaging and transportation?

A: Yes, we can adapt the packaging and transportation forms according to your requests.

However, please note that you will need to cover any additional costs and differences incurred during this period.

Q5. How does your factory do regarding quality control?

A: Quality is our top priority. We place significant emphasis on meticulous quality control from the start of production to its completion.

Q6. How long is the delivery time?

A: The delivery time is typically 7-20 working days after payment confirmation.

For urgent orders, we will expedite the production process to ensure timely delivery.

Q7. What is your Payment?

A: 100% T/T in advance, Western Union (for small orders).

B: 30% T/T in advance and the remaining 70% before shipment.

C: 100% Irrevocable LC at sight (for large orders).

Q8: Can you make DDQ (Deep Drawing Quality)?

A: Yes, we can. Our materials are suitable for stainless steel pots, sinks, bowls, etc. Provide your usage details, and we will adjust the mechanical properties accordingly.

Q9: How to get a sample?

A: FREE samples are available for your inspection and testing. For small sample pieces, we may cover courier costs, depending on the circumstances.

Q10: Which country have you exported to?

A: We have exported stainless steel materials to countries including Vietnam, Thailand, Turkey, Russia, Morocco, Korea, India, Pakistan, UAE, Ukraine, and others.

Duplex 2507 (UNS S32750) is a super duplex stainless steel with a composition of 25% chromium, 4% molybdenum, and 7% nickel. Designed for high-demand applications requiring exceptional strength and corrosion resistance, it is ideal for chemical processes, petrochemical, and seawater equipment. This steel exhibits outstanding resistance to chloride stress corrosion cracking, high thermal conductivity, and a low thermal expansion coefficient. Its rich chromium, molybdenum, and nickel content provides excellent resistance to pitting, crevices, and general corrosion.

APPLICATIONSOil and gas industry equipment

Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

Chemical process industries, heat exchangers, vessels, and piping

Desalination plants, high pressure RO-plant, and seawater piping

Mechanical and structural components, high-strength, corrosion-resistant parts

Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

ASTM/ASME ...…. A240 - UNS S32750

EURONORM...... 1.4410 - X2 Cr Ni MoN 25.7.4

GENERAL CORROSION

The high chromium and molybdenum content of 2507 renders it highly resistant to uniform corrosion by organic acids like formic and acetic acid.

It offers excellent resistance to inorganic acids, particularly those with chlorides.

It can be effectively used in dilute hydrochloric acid.

Pitting is not a concern in areas below the borderline in this figure, though crevices should be avoided.

Its low carbon content significantly reduces the risk of carbide precipitation at grain boundaries during heat treatment.

The alloy is highly resistant to carbide-related intergranular corrosion.

The duplex structure of our 2507 Stainless Steel Plate offers unparalleled resistance to chloride stress corrosion cracking (SCC), ensuring durability and reliability in even the harshest marine environments.

Elevate your marine applications with 2507 Stainless Steel, a material that surpasses 2205 in both corrosion resistance and strength, providing unmatched performance.

The 2507 Stainless Steel Plate is an ideal choice for offshore oil and gas industries. Its exceptional resistance to high brine levels, whether naturally occurring or injected, enhances recovery and ensures longevity.

Utilize varied testing methods to accurately determine the pitting resistance of our 2507 stainless steel in chloride-containing solutions, ensuring optimal performance.

Experience superior protection with our highly resistant 2507 stainless steel, engineered to withstand crevice corrosion effectively.

For hot working, 2507 should be processed between 1875°F and 2250°F. Follow this with a solution anneal at a minimum of 1925°F, completed by a rapid air or water quench to ensure peak performance.

Cold Forming2507 Stainless Steel is designed to be compatible with most standard forming processes for stainless steel. Given its higher yield strength and lower ductility compared to austenitic steels, fabricators may require increased forming forces, larger bending radii, and allowances for springback. While procedures like deep drawing and stretch forming are more challenging, a solution anneal and quench are recommended for deformations exceeding 10%.

Heat TreatmentPost hot or cold forming, 2507 should be solution annealed and quenched at a minimum of 1925°F, followed by a rapid air or water quench. For optimal corrosion resistance, heat-treated products should undergo pickling and rinsing.

Welding2507 Stainless Steel boasts excellent weldability and can be joined to itself or other materials using SMAW, GTAW, PAW, FCW, or SAW methods. Utilize 2507/P100 filler metal for achieving the desired duplex weld structure.

2507 Stainless Steel typically does not require special measures, except to prevent condensation on cold metal surfaces.

Discover our range of stainless steel sheets, available in exquisite finishes: brushed, 2B smooth, or 8K mirror finish, each designed to meet the highest standards of aesthetic and functionality.

Each stainless steel sheet we supply is protected with a film on the finished side, which can be easily peeled off post-fabrication or installation, ensuring a pristine, mark-free surface. The back side remains unfinished.

2205 Grade Stainless Steel Sheet is a versatile and widely used option, known for its excellent weldability, formability, and corrosion resistance.

Company Profile

Zhongzheng Stainless Steel Co., Ltd. is a China-based manufacturer specializing in R&D, production, and distribution of stainless steel products. Established in the early 2000s, it serves industries including construction, machinery, food/medical equipment, and energy with precision tubes, sheets, profiles, and custom components.

Contact Us

- Zhongzheng Stainless Steel Co., Ltd.

- Contact nameLaijing Bu Chat Now

- AddressRoom 104-07, Building 5, Jinghu Technology Park Huanajinghu Garden, Donglihu Subdistrict Dongli District,

Product Categories

New Products

-

Discount Price Stainless Steel 201 316 430 Coil Strip Ss 304 Cold Rolled Stainless Steel Coil

-

High Quality Factory 2ba Surface 430 Stainless Steel Coil

-

Inconel 690 (UNS N06690/Alloy 690) Nickel Alloy Plate Aerospace & Aeronautical Grade High-Temperature & Corrosion Resistant ASTM B168 Standard

-

Premium 0.3-0.5mm Grade 304 201 Mirror 8K Stainless Steel Coil for Construction

-

304 Stainless Steel High Quality 201 304 316 403 Plate/Sheet/Coil/Strip for Construction Equipments

-

Ss 210 304 316 316L 309 310 310S Stainless Plate, Corrosion-Resistant Steel

-

Nickel Alloy Plate Corrosion Resistant Monel K500 400 Sheet Nitronic 30 60 90 Alloy Steel Plate Sheet

-

Nickel Alloy Plate Corrosion Resistant Monel K500 400 Sheet Nitronic 30 60 90 Alloy Steel Plate Sheet

-

Good Service 300 Series Thick 0.1-3mm China Ss 301 304 316 321 Welded Pipe Stainless Steel Tube Supplier

-

New Arrivals No Welds Pipe SUS304/316 Sanitary Seamless Tubes/Pipe for Pharmaceutical Use

-

304 304L 316 316L Polished Hairline Ss Round Seamless Steel Tube Stainless Steel Sanitary Mirror Tubing

-

321/ 08X18h10t Stainless Steel Tubes for Industrial Use

-

Discount Price Stainless Steel 201 316 430 Coil Strip Ss 304 Cold Rolled Stainless Steel Coil

-

Hot Sale Hot/Cold Rolled 304 316 Mirror Stainless Steel Coil Customizble Size

-

High Temperature and Corrosion Resistant Brushed Mirror Finish with 304 310 316 Stainless Steel Plate

-

Nickel Based Alloy Inconel 690 Corrosion Resistant Steel Plates Can Be Used in Engines

-

Factory Sale Top Quality 0.8mm Thickness 304 316 Stainless Steel Coil

-

Corrosion Resistant Marine Aluminum 5083 Aluminum Plate H111/H116 Complete Specifications

-

Nickel Based Alloy Inconel 690 Corrosion Resistant Steel Plates Can Be Used in Engines

-

Premium Corrosion-Resistant Stainless Steel Plate for Industrial Durability

-

AISI Wholesale 201/304/310/316 Round Bars with Different Diameters Stainless Steel Bar

-

Long-Lasting ASME SA778 904L DN200 18/8 Aus Cold Drawn Stainless Steel Pipe for Petroleum

-

ASTM A312/A312M TP321H Stainless Steel Seamless Pipe/Tube

-

Esang Ss Tube Manufacturer Handrail Polished Brushed Round 2 Inch Welded 304 Stainless Steel Pipe

Popular Searches

- building material

- stainless steel

- roofing sheet

- steel bar

- galvanized steel

- Stainless Steel Strip

- steel plate

- steel sheet

- steel coil

- Stainless Steel Coil

- Galvanized Steel Sheet

- ppgi

- Steel Sheet Coil Strip

- gi

- galvanized coil

- ppgi steel coil

- tinplate

- Steel Strip Coil

- duplex steel sheet

- Duplex Steel Coil

- stainless steel

- hot rolled

- Stainless Steel Sheet

- metallurgy

- Stainless Steel Strip

- Stainless Steel Plate

- welded pipe

- Stainless Steel Coil

- cold rolled

- Steel Plate Sheet

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Stainless Steel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Laijing Bu

Hi there! Welcome to my shop. Let me know if you have any questions.

Laijing Bu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile