Product Description

I. Basic Product Information

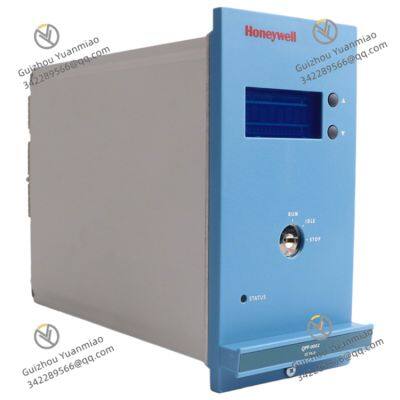

HONEYWELL FC-QPP-0002 is a system module that holds an important position in the field of industrial automation, meticulously developed by Honeywell, a leading brand in the industry. With years of profound technical accumulation and rich industry experience, Honeywell has always been renowned for its excellent product quality and reliable performance. FC-QPP-0002, originally produced in the United States, inherits Honeywell's consistent high-standard production technology. This module belongs to the category of DCS system main processor modules, with a clear product number of FC-QPP-0002. In terms of physical specifications, its dimensions are 17.8 x 11.4 x 4.4 cm, and its weight is approximately 0.9 kg. This design balances functional integration and installation convenience, enabling it to flexibly adapt to various spatial layouts of industrial equipment. In terms of supply, the total supply is sufficient, and fast delivery is usually achievable, generally within 3 days, providing strong support for the advancement of enterprise projects. The product is new and original, and a certain period of warranty service is provided to ensure users' worry-free use. In the procurement process, although the price will fluctuate with the market, it generally has a high cost performance, and there are various procurement channels, making it convenient for enterprises to obtain.

II. Technical Characteristics

(I) High-performance Processing Core

Multi-core Collaborative Operation: FC-QPP-0002 is equipped with four independent processors inside. This unique multi-core architecture design endows it with powerful parallel processing capabilities. In industrial automation scenarios, it is often necessary to simultaneously handle a large number of tasks such as data collection from different sensors, complex control logic operations, and equipment status monitoring. Multiple processors can be respectively responsible for tasks of different types or in different regions. For example, one processor focuses on the rapid collection and preliminary sorting of real-time data, another performs complex control algorithm operations, and the other processors are used for communication coordination between devices and monitoring of system status. All processors work collaboratively, greatly improving data processing efficiency and speed, ensuring that the system can respond timely and accurately to various changes in the industrial field.

Advanced Instruction Set and Cache Architecture: It adopts an advanced instruction set, which can efficiently execute various complex operation instructions, whether simple numerical calculations or instructions unique to the industrial control field such as logical judgment and signal conversion, all can be completed quickly and accurately. At the same time, it is equipped with a high-performance cache architecture, including L1 cache, L2 cache, and even L3 cache under some special designs. The existence of cache greatly reduces the time for the processor to read data from memory. When the processor needs to frequently access certain data or instructions, it can directly obtain them quickly from the cache, significantly improving the overall operation speed, just like building a high-speed data "reservoir" for the processor, which can meet its operation needs at any time, ensuring the smoothness and efficiency of the industrial automation system.

(II) High-reliability Design

Quad-Module Redundancy (QMR) Technology: It employs Quad-Module Redundancy (QMR) technology, which is a key design to ensure high system reliability. In industrial production, once a system fails, it may lead to serious production interruptions, equipment damage, or even safety accidents. QMR technology operates through four functional modules with the same function in parallel, and each module independently processes the same data and tasks. When one of the modules fails, the system can automatically identify it and quickly switch to other normal modules to continue working without affecting the overall operation of the system. For example, in the continuous chemical production process, even if a module has a short-term failure due to electrical interference, the QMR technology of FC-QPP-0002 can ensure the continuous and stable operation of the control system, ensuring that the chemical reaction proceeds according to preset parameters, and avoiding production accidents and product quality problems caused by system failures.

Real-Time Operating System (RTOS): It is equipped with a Real-Time Operating System (RTOS), whose most prominent feature is that it can provide deterministic performance for the system. In industrial automation control, there are extremely high requirements for the time accuracy of task execution. For example, in the scenario of precise motion control of robots, each action of the robot needs to be completed accurately at a specific time point; otherwise, it may lead to action deviations or even equipment collisions. RTOS can accurately schedule various tasks in the system, ensuring that each task can be completed within the scheduled time, guaranteeing the precision and stability of the industrial control process, and laying a solid foundation for the safe and efficient operation of industrial production.

(III) Electrical and Environmental Adaptability

Wide Voltage Input Range: It supports a wide voltage input, generally adapting to a relatively wide range of operating voltage fluctuations, for example, it can operate stably under voltage fluctuations within a certain range. This characteristic enables it to work reliably in different industrial power supply environments, whether in remote industrial areas with poor power supply stability or in large industrial plants with complex power systems and prone to voltage fluctuations. There is no need to worry about the module failing to work normally or its performance declining due to voltage issues, effectively improving the applicability and reliability of the module, and ensuring the continuous and stable operation of the industrial automation system under various power supply conditions.

Wide Operating Temperature Range: It has a wide operating temperature range, capable of stable operation in an ambient temperature of -20°C to +60°C. Some extended models with special design and optimization can even work normally in extreme temperature environments of -40°C to +85°C. In high-temperature industrial environments such as steel smelting, FC-QPP-0002 can withstand high temperatures, continuously and stably perform data processing and equipment control; in outdoor industrial operation scenarios such as oil extraction in cold regions, it can also operate normally in low-temperature environments, ensuring that industrial production is not overly restricted by temperature factors, and greatly expanding its application scenarios.

III. Functional Highlights

(I) Communication and Data Interaction Functions

Rich and Diverse Communication Interfaces: It is equipped with a variety of communication interfaces, supporting common interface types such as Ethernet, RS232, RS485, and USB. In industrial automation systems, different devices may adopt different communication interfaces and protocols. The rich interface configuration of FC-QPP-0002 enables it to easily connect and communicate with various devices. In an industrial automation production line containing equipment of multiple brands, high-speed data transmission with the host computer can be realized through the Ethernet interface, achieving remote monitoring and the issuance of control instructions; the RS485 interface can be used for stable communication with numerous on-site sensors and actuators, real-time collection of equipment operation data and control of their actions, effectively solving the problem of equipment communication compatibility in industrial systems, and ensuring the smooth data interaction of the system.

Multi-Protocol Communication Support: In addition to rich interfaces, it also supports multiple communication protocols, such as common industrial communication protocols like Modbus and MQTT. The Modbus protocol is widely used in the industrial field, and many traditional industrial devices use this protocol for communication. The support of FC-QPP-0002 for the Modbus protocol enables it to seamlessly connect these traditional devices, realizing the intelligent upgrading and unified management of old devices. As a lightweight IoT communication protocol, the MQTT protocol, in the context of the rapid development of the Industrial Internet of Things, facilitates FC-QPP-0002 to realize data interaction between devices and the cloud, making it easy for enterprises to build cloud platform-based industrial monitoring and management systems and improve the intelligence level of industrial production.

(II) Security Protection Functions

Secure Boot Mechanism: A secure boot mechanism is set up to effectively prevent unauthorized access. In industrial control systems, data security and system security are crucial. Once subjected to malicious attacks or illegal access, it may lead to serious consequences such as leakage of production data and malicious manipulation of equipment. The secure boot mechanism of FC-QPP-0002 performs integrity verification on the boot program, system configuration, and key data when the system starts. Only the system that passes the verification can start and run normally, eliminating the intrusion of illegal programs or malicious software from the source, and ensuring the safe and stable operation of the industrial automation system.

Intrinsic Safety Certification (IS): It has obtained Intrinsic Safety Certification (IS), which means it is very suitable for use in hazardous environments. In industrial scenarios such as petroleum and chemical industries where flammable and explosive substances exist, electric sparks generated by electrical equipment may cause serious safety accidents. FC-QPP-0002 has undergone intrinsic safety design and certification. In normal operation or fault conditions, the electric sparks or thermal effects generated by it are strictly controlled within the range that will not ignite the surrounding flammable and explosive substances, providing a safe and reliable solution for industrial automation control in hazardous environments and ensuring the safety of the production process.

(III) Flexible Configuration Functions

Multiple Configuration Options: It provides a variety of configuration options to meet the personalized needs of different industrial application scenarios. Different industrial projects have different requirements for the functions and parameters of system modules due to differences in production processes, control accuracy requirements, and equipment layouts. FC-QPP-0002 can be flexibly configured in terms of processor computing resource allocation, communication interface settings, data storage methods, etc., according to user needs. In an industrial monitoring project with extremely high requirements for real-time data collection, more processor resources can be allocated to data collection tasks, and communication interface settings can be optimized to improve data transmission speed; in an industrial recording project with large data storage capacity requirements, the module configuration can be adjusted to increase data storage space, maximizing the satisfaction of the actual needs of different projects.

Convenient Configuration Operation: The configuration process is relatively simple, and users can complete the configuration work in a short time without having profound professional technical knowledge. Usually, the module is equipped with easy-to-use configuration software. Through an intuitive graphical operation interface, users can easily complete the configuration of the module only by setting parameters according to prompts. This greatly reduces the technical difficulty and time cost for enterprises in the process of system integration and debugging, enabling enterprises to apply FC-QPP-0002 to actual production more quickly, accelerate the implementation progress of industrial automation projects, and improve enterprise production efficiency.

ABB REF615C_E HCFEAEAGABC2BAA11E Protective Relay Module

ABB XVC722AE101 3BHB002751R0101 Controller

ABB XVC767AE102 3BHB007209R0102 Controller

ABB XVC767AE105 3BHB007209R0105 Controller Module

ABB XVC770BE102 3BHE021083R0102 Controller Module

ABB XVC768101 3BHB007211R101 Printed Circuit Board

ABB XVC768115 3BHB007211R115 Printed Circuit Board

ABB LDMUI-01 I/O Powerhouse Module

ABB LDSTA-01 Automation I/O Module

ABB LDMTR-01 I/O Module

ABB PM866 3BSE050200R1 Processor Unit Kit

ABB PM858 3BSE093350R1 Processor Unit Kit

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.

yezi

Hi there! Welcome to my shop. Let me know if you have any questions.