Home > Products > Shredder&Crusher > Dual Shaft Tire Shredder

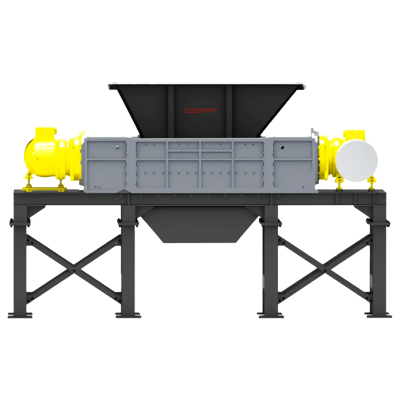

Dual Shaft Tire Shredder

- T/T L/C PayPal D/P Western Union Other

You May Like

Product Details

| Type | Powerful Plastic shredders | Automation | Automatic | |

| Computerized | Computerized | Origin | China |

Product Description

The dual-shaft tire shredder is a robust and highly efficient machine engineered to meet the demanding needs of tire recycling, solid waste reduction, and resource recovery industries. Designed to handle all types of waste tires—from passenger vehicle tires to heavy-duty truck and OTR (off-the-road) tires—this shredder plays a vital role in turning waste rubber into valuable material suitable for further processing or direct use.

As global regulations and environmental awareness regarding waste tire disposal continue to grow, businesses need reliable solutions to break down these bulky and non-biodegradable materials. The Dual Shaft Tire Shredder addresses this challenge with advanced cutting technology, a durable structure, and powerful drive systems that guarantee long-lasting, high-capacity performance.

Product OverviewTires pose a significant recycling challenge due to their high elasticity, volume, and embedded metal reinforcement. Conventional crushers often struggle to process such resilient materials. The dual-shaft tire shredder, however, is specifically designed for this purpose. Using two slow-speed, high-torque shafts equipped with intermeshing cutting blades, the machine can easily shear through thick rubber and steel wire with minimal vibration and noise.

The result is a uniform, manageable tire shred that can be further processed into rubber mulch, crumb rubber, or used in applications such as alternative fuel (TDF), playground surfaces, asphalt modification, and civil engineering materials.

Main FeaturesDual Shaft Cutting System

The core of the shredder consists of two counter-rotating shafts fitted with replaceable and wear-resistant blades. These shafts grip and tear tires using low-speed rotation, which reduces energy consumption, noise, and wear while providing high torque output. This ensures maximum efficiency in shredding even the toughest tire materials, including those with heavy steel bead reinforcement.

Heavy-Duty Construction

Made from high-grade steel, the machine’s frame and chamber are built for maximum durability. Reinforced sidewalls, integrated shaft sealing, and robust bearing supports ensure that the shredder can operate continuously under harsh industrial conditions.

High Torque, Low Speed Drive

The dual-shaft tire shredder is powered by either an electric or hydraulic motor, depending on the configuration. The low-speed rotation, typically between 10–25 RPM, reduces heat build-up and extends the life of the cutting blades while providing exceptional torque to tear through dense and flexible tire material.

Automatic Reverse Protection

To prevent blade jamming and protect the motor from overload, the shredder is equipped with an automatic reverse system. When excessive resistance is detected, the shafts reverse briefly to clear blockages and then resume normal operation automatically.

Customizable Output Size

The output size of shredded tire material can be adjusted by changing the blade design or configuring downstream screens and conveyors. This makes the shredder versatile for different recycling applications, whether the target is TDF, granules, or pre-crushed feedstock for finer grinding.

User-Friendly Control System

The integrated control panel is PLC-based and features an intuitive interface with fault alarms, operational data, and programmable settings. Operators can monitor shredder performance and make quick adjustments as needed.

Low Maintenance and Easy Cleaning

With removable chamber covers and easy-access blade assemblies, maintenance and cleaning tasks can be carried out quickly. The blades are designed for long service life, and re-sharpening or replacing them is straightforward.

Shredding Capacity: 2 to 20 tons per hour (depending on model and material)

Motor Power: 45–150 kW

Shaft Speed: 10–25 RPM

Cutting Chamber Size: 1200 mm × 800 mm (customizable)

Output Size: 50–150 mm (adjustable or screen-controlled)

Blade Material: Hardened alloy steel or customized as per client requirement

Control System: Siemens PLC with touchscreen

Drive Type: Electric or hydraulic (optional)

The dual-shaft tire shredder is widely used in:

Tire recycling plants

Municipal solid waste (MSW) facilities

Rubber processing industries

Cement kilns (for TDF processing)

Landfill pre-treatment systems

Waste-to-energy operations

Suitable materials include:

Passenger car tires

Truck and bus tires

Agricultural and OTR tires

Conveyor belts

Rubber bumpers and mats

Industrial rubber waste

Improved operational efficiency: With high throughput and minimal downtime, the shredder allows businesses to process more tires in less time.

Reduced labor costs: Fully automatic operation and low maintenance design minimize manual handling and oversight.

Enhanced environmental compliance: Tire shredding is a crucial step in meeting recycling regulations and reducing landfill impact.

Flexible integration: The machine can operate as a standalone unit or be integrated into a complete recycling line with conveyors, magnetic separators, and granulators.

Long-term cost savings: Durable construction, efficient power use, and extended blade life result in reduced operating costs over time.

The dual-shaft tire shredder is an essential asset for any company involved in tire disposal, rubber recycling, or waste-to-energy production. Its ability to break down tough tire materials with ease and efficiency makes it a preferred solution in both developed and emerging markets. Whether you’re starting a new tire recycling operation or upgrading your existing system, this machine offers the power, reliability, and flexibility needed for long-term success.

Contact us today to learn more about customization options, technical support, and pricing. Our team is ready to help you design the most effective shredding solution for your specific needs.

Contact Us

- Nantong GIGAPA Technology Co., Ltd.

- Contact nameWujingjing Chat Now

- AddressZhihui Valley, Rugao, Nantong, Jiangsu Province, China, Nantong, Jiangsu

Product Categories

| Baling Machine | Shredder&Crusher | Hydraulic Components |

New Products

-

Cardboard Vertical Baler

-

Door Cover Hydraulic Metal Baling Press

-

Fully Auto Paper Horizontal Baler

-

Fully Auto Plastic Horizontal Baler

-

Wood Chip Shaving Machine

-

Industrial Hydraulic Press Baler

-

Fully Auto Textile Horizontal Baler

-

Fully Automatic Baler for Textile Waste

-

Fully Automatic Horizontal Baler (PP/PET Strap)

-

Fully Automatic Strapping Baler-(Iron Wire)

-

Hydraulic Horizontal Baling Press

-

Hydraulic Horizontal Baling Press

Popular Searches

- recycling machine

- rubber machinery

- crushing machine

- plastic shredder

- single shaft shredder

- double shaft shredder

- metal shredder

- scrap metal shredder

- waste tire shredder

- tire crusher

- rubber cutting machine

- tire recycling

- waste tire recycling line

- rubber crusher

- tire recycling line

- rubber recycling

- rubber shredder

- tire cutter

- tire grinder

- tire recycling shredder

- car tire shredder

- truck tire shredder

- wood shredder

- plastic shredder

- tire recycling machine

- tyre recycling

- single shaft shredder

- double shaft shredder

- metal shredder

- scrap metal shredder

Recommended Products

- Solid Carbide Boring Mini-Bar Customized Boring Cutter Milling Cutter Cutting Tool

- Carbide T-Type Dovetail Shape Milling Cutter Non-Standard Milling Tool Customized Cutting Tools

- Solid Carbide End Mill Dovetail Milling Cutter Customized Dovetail Type T-Type Milling Cutter Non-Standard Cutting Tool

- Customized Milling Cutter V Sharp Milling Tool Non Standard Cutting Tool V Shape End Mill

- Tungsten Carbide Dovetail Milling Cutter Customized Dovetail Type T-Type Milling Cutter End Mill Cutting Tool

- Customized Milling Cutter V Sharp Milling Tool Non Standard Cutting Tool

- DLC Coating End Mill Single Flute Milling Cutter Mirror Polished End Mill Aluminum End Mill Rainbow Colorful Coating End Mill

- Carbide Blue Coating End Mill CNC Cutting Tools Original for Stainless Steel

- CNC Milling Cutter 4 Flutes End Mill Tungsten Carbide End Mill for Steel Metal Cutting HRC45/55/63/65

- Six Flutes Milling Tool Nano Blue Coating End Mill Fine Milling Cutter

- 6 Flutes Milling Tool Nano Blue Coating Good Performance Six Flutes End Mill Fine Milling Cutter High Quality End Mill

- 6 Flutes End Mill Nano Blue Coating End Mill High Quality Milling Cutter Milling Tool

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Crusher

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Wujingjing

Hi there! Welcome to my shop. Let me know if you have any questions.

Wujingjing

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile