Home > Products > Hygienic grade piping series > TP304/304L Tp316/316L ASTM A249 Welded Austenitic Stainless Steel Pipes for Boiler

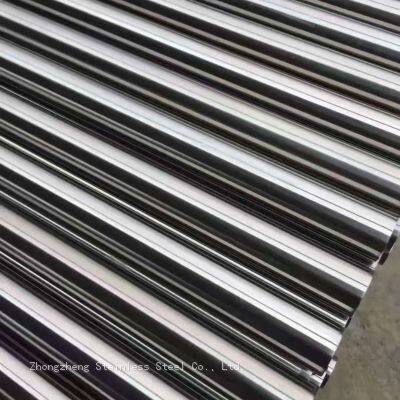

TP304/304L Tp316/316L ASTM A249 Welded Austenitic Stainless Steel Pipes for Boiler

- 100000 Ton / Tons per Month

- NINGBO/SHANGHAI/TIANJIN/XIAMEN

- T/T

- 25 days

You May Like

-

Bright Annealed Stainless Steel Seamless Tube En10216-5 Tc1 D4 / T3 1.4301 1.4307 1.4401 1.4404, 1inch Bwg 16 20feet

-

ASTM A269 Tp316L 12.7X0.89 12.7X1.24 12.7X1.65 Bright Annealing Stainless Steel Seamless Tube

-

ASTM A269 Tp316L Bright Annealed 320 Polished Stainless Steel Seamless Tube

-

Cold Drawn Rolling Rolled Carbon Alloy Stainless Precision Bright Steel Tube

-

Precision Bright Welded Seamless Golden Silver Round Stainless Steel Pipe Tube

-

Round Stainless Steel Pipe ASTM A270 A554 SS304 316L 316 310S 440 1.4301 321 904L 201 Square Pipe Inox Ss Seamless Tube

Product Description

| Reverse-Bend Test Requirement | ||||||||||||

| A section 4 in. [100 mm] minimum in length shall be split longitudinally 90° on each side of the weld. The sample shall then be opened and bent around a mandrel with a maximum thickness of four times the wall thickness, with the mandrel parallel to the weld and against the original outside surface of the tube. The weld shall be at the point of maximum bend. There shall be no evidence of cracks, or of overlaps resulting from the reduction in thickness of the weld areas by cold working. When the geometry or size of the tubing make it difficult to test the sample as a single piece, the sample may be sectioned into smaller pieces provided a minimum of 4 in. of weld is subjected to reverse bending. NOTE 3—The reverse bend test is not applicable when the specified wall is 10 % or more of the specified outside diameter, or the wall thickness is 0.134 in. [3.4 mm] or greater, or the outside diameter size is less than 0.375 in. [9.5 mm]. Under these conditions the reverse flattening test of Specification A 1016/A 1016M shall apply. | ||||||||||||

| Grain Size Requirement | ||||||||||||

| The grain size of Grades TP309H, TP309HCb, TP310H and TP310HCb, as determined in accordance with Test Methods E 112, shall be No. 6 or coarser. The grain size of Grades TP304H, TP316H, TP321H, TP347H and TP348H, as determined in accordance with Test Methods E 112, shall be No. 7 or coarser | ||||||||||||

| Mechanical Tests and Grain Size Determinations Required | ||||||||||||

| Tension Test—One tension test shall be made on a specimen for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes. Flattening Test—One flattening test shall be made on specimens from each end of one finished tube, not the one used for the flange test, from each lot. Flange Test—One flange test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot. Reverse-Bend Test—One reverse-bend test shall be made on a specimen from each 1500 ft [450 m] of finished tubing. Hardness Test—Brinell or Rockwell hardness tests shall be made on specimens from two tubes from each lot. Hydrostatic or Nondestructive Electric Test—Each tube shall be subjected to either the hydrostatic or the nondestructive electric test. The purchaser may specify which test is to be used. Grain Size—Grain size determinations on grades TP309H, TP309HCb, TP310H and TP310HCb shall be made on the same number of tubes as prescribed for the flattening test. Heavily cold worked tubes (HCW) shall be capable of passing the weld decay test listed in Supplementary S7 with a weld metal to base metal loss ratio of 0.90 to 1.10. The test is not required unless S7 is specified in the purchase order. | ||||||||||||

| Permissible Variations in Dimensions | ||||||||||||

| Dimensional tolerances other than wall thickness tolerances shall be in accordance with Specification A 1016/ A 1016M. Wall thickness tolerances shall be 610 % of nominal wall for all tubing sizes. The wall thickness of the weld shall not exceed the wall thickness measured 90° from the weld by more than 6 % of the specified wall thickness or 0.004 in. [0.1 mm], whichever is greater. Requirements of 14.2 are not applicable when any of the following apply: When the specified wall thickness exceeds 12 % of the specified outside diameter; When the specified wall thickness exceeds 0.165 in. [4.2 mm]; When the specified OD exceeds 3 in. [76.2 mm]; or When the specified minimum yield strength given in Table 4 for the specified grade is 35 ksi [240 MPa] or greater. | ||||||||||||

| Workmanship, Finish, and Appearance | ||||||||||||

| Finished tubes shall have smooth ends free of burrs and shall not deviate from straightness by more than 0.030 in. [0.8 mm] in 3 ft (900 mm] of length. | ||||||||||||

| Surface Condition | ||||||||||||

| The tubes, after final heat treatment, shall be chemically descaled or pickled free of scale. When bright annealing is used, pickling or chemical descaling is not necessary. | ||||||||||||

| Forming Operations | ||||||||||||

| Tubes when inserted in the boiler shall stand expanding and beading without showing cracks or flaws. All tubes, when properly manipulated, shall be able to stand expanding and beading without showing cracks and flaws, and also shall stand all forging, welding, and bending operations necessary for application without developing defects. | ||||||||||||

| Stress-Relieved Annealed Tubes | ||||||||||||

| For use in certain corrosives, particularly chlorides where stress corrosion may occur, tubes in Grades TP304L, TP316L, TP321, TP347, and TP348 may be specified in the stress-relieved annealed condition. Details of these supplemental requirements shall be agreed upon by the manufacturer and the purchaser. When stress-relieved tubes are specified, tubes shall be given a heat treatment at 1550 to 1650 °F [845 to 900 °C] after roll straightening. Cooling from this temperature range may be either in air or by slow cooling. No mechanical straightening is permitted after the stress-relief treatment. Straightness of the tubes shall be a matter of negotiation between the purchaser and manufacturer. | ||||||||||||

| Surface ConditionMinimum Wall Tubes | ||||||||||||

| When specified by the purchaser, tubes shall be furnished on a minimum wall basis. Such tubes shall satisfy the minimum wall thickness requirements of Specification A 1016/A 1016M rather than the nominal wall requirements of this specification. In addition to the marking required by Section 18, the tubing shall be marked S2. | ||||||||||||

| Air Underwater Pressure Test | ||||||||||||

| When specified, the tubing shall be examined by the air underwater pressure test. | ||||||||||||

| Stabilizing Heat Treatment | ||||||||||||

| Subsequent to the solution anneal required in Section 6, Grades TP309HCb, TP310HCb, TP321, TP321H, TP347, TP347H, TP348, and TP348H shall be given a stabilization heat treatment at a temperature lower than that used for the initial solution annealing heat treatment. The temperature of stabilization heat treatment shall be at a temperature as agreed upon between the purchaser and vendor. | ||||||||||||

| Unstraightened Tubes | ||||||||||||

| When the purchaser specifies tubes unstraightened after final heat treatment (such as coils), the straightness requirement of Section 12 shall not apply and the minimum yield strength of Table 3 shall be reduced by 5 ksi [35 MPa]. S5.2 On the certification, and wherever the grade designation for unstraightened tubing appears, it shall be identified with the suffix letter “U” (for example, 304-U, 321-U, etc.). | ||||||||||||

| Intergranular Corrosion Test | ||||||||||||

| When specified, material shall pass intergranular corrosion tests conducted by the manufacturer in accordance with Practices A 262, Practice E. NOTE S6.1—Practice E requires testing on the sensitized condition for low carbon or stabilized grades, and on the as-shipped condition for other grades. A stabilization heat treatment in accordance with Supplementary Requirement S4 may be necessary and is permitted in order to meet this requirement for the grades containing titanium or columbium, particularly in their H versions. | ||||||||||||

| Weld Decay Test | ||||||||||||

| This test is not applicable to alloys with a nickel content $ 19.0 % or a molybdenum content $ 4.00 %, or both. When specified by the purchase order, one sample from each lot of tubing shall be subjected to testing in a boiling mixture of 50 % reagent grade hydrochloric acid and 50 % water. Approximately 2-in. long samples shall be prepared from a production length of tubing. Shorter, 1-in. samples may be used for small diameter (1/2-in. and below) tubing. Split the sample longitudinally to allow for easy micrometer measurements. The sample may be one piece which contains the weld and at least 90° of base-metal to one side of the weld. Alternately, the sample may be two separate pieces with one containing the weld and a similar size section from the balance of the tube opposite the weld consisting of 100 % base metal. Remove all burrs and sharp edges by lightly grinding. Remove dust and grease by cleaning with soap and water or other suitable solvents. Then, place sample(s) in the flask. It is not recommended to test more than four samples together, or to mix alloy types. Prepare the hydrochloric acid solution by slowly adding reagent grade (approximately 37 %) hydrochloric acid to an equal volume of distilled water. (Warning—Protect eyes and use rubber gloves when handling acid. Mixing shall be done under a hood and testing shall be run under a hood.) The test container shall be a 1-L Erlenmeyer flask equipped with ground-glass joints and an Ahlin condenser. The volume of the solution shall be approximately 700 mL. Measure the thickness of the tube at five locations along the weld area and at five locations along the base-metal section. In both cases, take measurements at approximately equal longitudinal intervals along the section lengths. Make these measurements with a sharp pointed micrometer accurate to at least 0.001 in. The micrometer must be suitable for measuring the small features in the surface after testing. Typical pin micrometers have tapered anvils with a tip radius of less than 0.015 in. Immerse the samples into the solution. Add boiling chips and bring to a boil. Allow the chips to remain boiling throughout the test. The time of testing shall be that which is required to remove 40 to 60 % of the original base-metal thickness (usually 2 h or less). If more than 60 % of the base-metal thickness remains, the sample may be removed after 24 h. At the end of the test period, remove the samples from the solution, rinse with distilled water, and dry. After exposure to the test solution, repeat the tubethickness measurement as in S7.6. If the thinning is not uniform across the width of the weld, then two sets of weld-metal measurement are required. One set of measurements is to be taken along the centerline of the weld. The second set of measurements is to be taken in the thinnest area of the weld. Calculate the corrosion ratio, R, for both sections of the weld as follows in Eq1: where: Wo = average weld-metal thickness before the test, W = average weld-metal thickness after the test, Bo = average base-metal thickness before the test, and B = average base-metal thickness after the test. A corrosion ratio of 1.25 or less for the thinnest section of the weld is permissible. Other criteria, such as a ratio of 1.00 or less, may be specified upon agreement between the producer and the purchaser. | ||||||||||||

| Special Applications | ||||||||||||

| For special applications, such as hydraulic expansion of tubes into tube sheets, there shall be no dimensional indication of the weld. Tubes ordered to this requirement shall bear the additional marking of NB. | ||||||||||||

| Additional Testing of Welded Tubing per ASME Request | ||||||||||||

| Each tube shall be subjected to an ultrasonic inspection employing Practices E 273 or E 213 with the rejection criteria referenced in Specification A 1016/A 1016M. If Practice E 273 is employed, a 100 % volumetric inspection of the entire length of each tube shall also be performed using one of the nondestructive electric tests permitted by Specification A 1016/A 1016M. The test methods described in the supplement may not be capable of inspecting the end portions of tubes. This condition is referred to as end effect. This portion, as determined by the manufacturer, shall be removed and discarded. In addition to the marking prescribed in Specification A 1016/A 1016M, “S9” shall be added after the grade designation. | ||||||||||||

Company Profile

WORKSHOP

REASONS FOR CHOOSING US

Quality Control

Company Profile

Zhongzheng Stainless Steel Co., Ltd. is a China-based manufacturer specializing in R&D, production, and distribution of stainless steel products. Established in the early 2000s, it serves industries including construction, machinery, food/medical equipment, and energy with precision tubes, sheets, profiles, and custom components.

Contact Us

- Zhongzheng Stainless Steel Co., Ltd.

- Contact nameLaijing Bu Chat Now

- AddressRoom 104-07, Building 5, Jinghu Technology Park Huanajinghu Garden, Donglihu Subdistrict Dongli District,

Product Categories

New Products

-

Stainless Steel Pipe Micro Fine Tube for Industry

-

Manufacture Customized ASTM 201 304 316L 316 Ss 202 Tubes Stainless Steel Round Pipe

-

AISI ASTM 201 304 316L 410 420 Cold Rolled 8K Mirror Polished Hairline Satin Welded Seamless Stainless Steel Pipe for Decoration Tube

-

High Quality Glossy Mirror Thick SA-240 Stainless Steel Sheets Plates for PVC Card Press Laminating

-

Good Service Bar Stainless Alloy Mould Hot Rolled Incoloy 800 Steel Plate

-

Stainless Scrap Hot Rolled Roofing Sheet Steel Plate Incoloy 800

-

China Customized Stainless Steel Sheet SA-240 SB-688

-

Chemloal plants ASTM 240/Uns S32100 Steel Sheet for Petroleum Refining Stainless Steel Plate

-

GB BS Cold Rolled Alloy 0.5mm1200mm2400mm Incoloy 800 Steel Plate

-

High Quality BS Stainless Scrap Nickel Cold Rolled Alloy Steel Plate Incoloy 800

-

Good Service Bar Stainless Alloy Mould Hot Rolled Incoloy 800 Steel Plate

-

Corrosion Resistant Type?347 / 347H Stainless Steel Plate - Austenitic Stainless Steel, Used for Chemical Equipment

-

Heavy-oil fired furnace parts,Steam generator in pressurized water reactors

-

Sheathed heater,Fumace parts,Heat exchanger

-

AISI 201 304 304L 316 316L 430 410 Stainless Sheet 2b Ba Hl Mirror Surface 316 Stainless Steel Price Per Kg

-

Supply Wholesale Price Coil Stainless Steel Sheet Plate ASTM A240 AISI 304 321 316L, 310S,Polished Stainless Steel Plate

-

Hot Rolled 3mm 5mm 10mm Thickness AISI 304 304L 316L Stainless Steel Plate

-

Factory Price ASTM 2b Hl No. 4 8K Surface Hr /Cr Stainless Steel Plate (201 202 304 304L 316 316L 309 309S 310 310S 321 430 2205 2507 253mA)

-

Ss Hot/Cold Rolled 201 304 321 316 316L Stainless Steel Plate

-

Premium 304 Stainless Steel Cold-Rolled Brushed Plate for Laser Cutting

-

Stainless Carbon Steel Hydrapulper Drilled Pressure Screening Rotor Plate for Pulp and Paper

-

Best Products AISI ASTM SUS Ss 304L 310S 202 321 316 410 430 316L 201 304 Stainless Steel Sheet/Plate for Decoration

-

A36 Ss400 Q235 Q355 Q345ms S275jr Plate Hot Rolled Low Carbon Steel Plate Coil Stainless Steel Plate Galvanized Plate Roof Plate Aluminum Plate

-

Stainless Carbon Steel Hydrapulper Drilled Pressure Screening Rotor Plate for Pulp and Paper Mill Machinery

Popular Searches

- Cnc Machining Part

- aluminum ingot

- container house

- face mask

- pillow block bearing

- lapel pin

- wheel loader

- farm tractor

- eyelash extension

- Protective Device

- Antistatic Shoe

- Esd Shoe

- Steel Pipe

- Pipe Tube

- Round Tube

- bright annealed

- water tube

- stainless steel pipe

- stainless steel tubing

- Steel Pipe Tube

- Rectangular Tube

- Stainless Steel Material

- seamless steel tube

- stainless steel welded pipe

- stainless steel coils

- Capillary Tube

- stainless steel seamless tube

- welded tube

- welding tube

- stainless steel welded tube

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Stainless Steel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Laijing Bu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Laijing Bu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile