- shandong hawkeye mechanical technology Co.,ltd

- Main products: AVI automatic visual inspection machine, semi-automatic light inspection machine, oral liquid, syrup automatic light inspection machine, tablet capsule inspection machine, cleaning & dryer , A-Z turnkey projects for phamaceutical products, ampoule visual inspection , vial visual inspection, Lyophilization visual inspection

Home > Products > visual inspection machine > lyophilized powders ,vial , glass ampoule visual inspection machine

lyophilized powders ,vial , glass ampoule visual inspection machine

- T/T L/C PayPal Other

You May Like

-

HVLD machine, high voltage leak detection

-

pharmaceutical products , oral liquid ,vial, glass ampoule visual inspection machine

-

glass ampoule visual inspection machine Shandong hawkeye pharmaceutical machinery

-

glass ampoule visual inspection machine

-

automatic visual inspection machine

-

lyophilized powders ,vial , glass ampoule visual inspection machine

Product Description

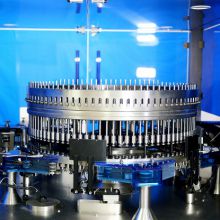

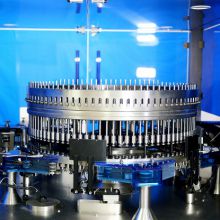

Automatic Ampoule and Vial Inspection Machine

Ampoule Vial Inspection Machines

Automatic Ampoule and Vial Inspection Machine

WE are manufacturing inspection systems for the pharmaceutical industry. automatic inspection machines for injectable pharmaceutical products contained in syringes, ampoules, vials, cartridges and bottles, guarantees precise optical alignment between cameras, lights and containers for superior detection performance.

Product Description

It is mainly used to inspect visible impurities (such as glass, metal scraps, fiber, hair, white powder and flakes etc.) and liquid level of Ampoules from 1 to 20ml and 2ml to 100 Vials, 30 ml to 250ml bottle or more customized. It can also check whether there are ashy top, Carbide point, cusp, bubble head and micro pore on the Glass ampoule and Vials.

Inspecting procedure:

Products to be inspected→ feed in → photoelectric inspection zone → rotate Ampoule & Vials – glass → stop → take pictures → bottle divided device distinguishes qualified Ampoule & Vials – glass and the rejects according to software instructions → Qualified Ampoule & Vials – glass and the rejects feed out separately.

Main Structure:

1. Rack → Vial-in feed conveying devices → Vial-in feed wheel→ rotary tray→ Vial-pressing device → rotary apparatus → cam lift → quick change size parts device → out feed wheel → qualified products/rejects collection plate.

2. Driving system, servo system → computer software processing system → control system

3. inspection camera → lighting device → light harrier → Light source servo tracking device → image processing system

Working Principle

First, use mechanical visual principle to inspect visible impurities (such as glass, metal scraps, fiber, hair, white powder, flakes etc.) in ampoule liquid, and check ashy top, Carbide point, cusp, bubble head, micro pore and liquid level of ampoule and vial , The inspected products are transferred to impurity inspect station by wheel, and it finished ashy top, Carbide point, cusp and bubble head inspection in the transfer process. On the impurity inspection stations, the product is braked static while it rotates in high speed, industrial cameras take a series of photos continuously on it and computer system analyze and compare those photos to judge whether impurities exist in the inspect product and finish liquid level inspection at the same time. Then, those products are transferred to micro pore and crack inspection stations by wheel.

Apply high frequency high voltage to both ends of inspected products, and judge whether micro pore and cracks exist on Glass Ampoule and Vial s or not by comparing the micro electric current. After inspection, the qualified products and rejects will be separated automatically.

Technical parameters:

· Inspecting items: visible impurities (such as glass, metal scraps, fiber, hair, white powder, flakes etc.), ashy top, Carbide point, cusp, bubble head, micro pore and liquid level

Contact Us

- shandong hawkeye mechanical technology Co.,ltd

- Contact nameLee Chat Now

Product Categories

| visual inspection machine |

New Products

-

Injections and Implanted Drug Products (Parenterals)—Product Quality Tests

-

tablet capsule automatic visual inspection machine

-

AVI ampoule visual inspection machine

-

AVI tablet capsule visual inspection machine

-

lyophilized powders ,vial , glass ampoule leak detection machine

-

lyophilized powders ,vial , glass ampoule cleaning machine

Popular Searches

- packing machine

- inspection camera

- third party inspection

- mask making machine

- screen machine

- inspection equipment

- video borescope

- cctv inspection camera

- inspection machine

- inspection system

- lab test

- optical inspection machine

- tensile test

- mask machine

- screen equipment

- drain inspection camera

- pipeline inspection

- inspection camera system

- inspection agency

- wear corrosion

- design temperature

- inspection report

- pharmaceutical chemical

- plant extract

- raw material

- pharmaceutical machine

- chemical product

- raw powder

- food additif

- pharmaceutical raw material

Recommended Products

- NAD β-Nicotinamide Adenine Dinucleotide//β-NAD

- NMN β-Nicotinamide Mononucleotide

- High purity top quality- peptide weightloss tirzepatide door to door factory

- HVLD machine, high voltage leak detection

- BFS leak detection automatic visual inspection machine

- Kyotorphin/ 70904-56-2?

- Carnosine / 305-84-0

- Pentapeptide-21

- Recombinant Human Keratinocyte Growth Factor-2 (rhKGF-2)

- SH-Oligopeptide-1/ 62253-63-8

- Oligopeptide-68 / 1206525-47-4

- Oligopeptide-20

Find Similar Products By Category

- Health & Medicine > Pharmaceutical Intermediate

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile