Home > Products > Surface Treatment > Papermaking drying cylinder

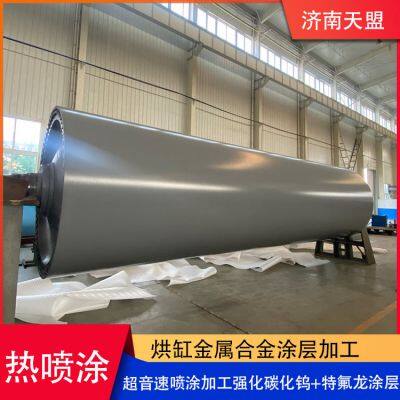

Papermaking drying cylinder

≥1 Square Meter

- 10000 Square Meter / Square Meters per Month

- T/T L/C PayPal D/P Western Union Other

You May Like

-

Machine industry Fluidized bed Thermal spraying processing Teflon preparation anti-corrosion wear-resistant can support customized

-

Surface treatment of filter core plate using plasma technology for corrosion prevention, wear resistance, and high temperature resistance

-

Surface treatment of machinery industry Thermal spraying plasma process anti-corrosion, wear-resistant and thermal insulation

-

Surface treatment in the mechanical industry, spraying tungsten carbide for corrosion prevention and wear resistance

-

Directly supplied by the manufacturer for laser cladding surface treatment, piston rod surface repair, anti-corrosion and wear-resistant

-

Repair of the surface of the drying cylinder by spraying tungsten carbide+Teflon anti-corrosion and wear-resistant non stick coating

Product Details

| Application | Metal Coating Machinery |

Product Description

In modern industry, drying cylinders are indispensable equipment in many production processes, especially in the papermaking industry. Over time, the surface of the drying cylinder may be damaged due to wear, corrosion or other factors, and at this point, effective repair is required. Spray repair of drying cylinders, as a common maintenance method, has received increasing attention in recent years. So, is the spray repair of the drying cylinder reliable?

First of all, we need to understand the different methods of spray repair for drying cylinders. Different repair methods can be selected based on the specific conditions of the drying cylinder. For example, supersonic spraying and arc spraying are both commonly used spraying techniques. Supersonic spraying uses high-temperature gas to accelerate the coating material to supersonic speed, thereby forming a dense coating. It is suitable for the surfaces of drying cylinders with high requirements for wear resistance and corrosion resistance. Arc spraying, on the other hand, heats the metal wire through an electric arc to form the spraying material, which is suitable for large-scale repairs.

When choosing a repair method, enterprises need to conduct an assessment based on the specific conditions of the drying cylinder. For instance, Jinan Tianmeng's thermal spray repair technology enjoys a good reputation in the industry. Its technical team can provide customized repair solutions based on different types of drying cylinders and the degree of damage. This flexibility enables the spray repair of drying cylinders to better meet the needs of customers.

To sum up, the spray repair of the drying cylinder is a reliable repair method, but its effect depends on multiple factors, including the selected repair technology, the materials used, the professional level of the construction team, and the later maintenance management. When enterprises carry out drying cylinder spraying repair, they should comprehensively consider these factors. As a leader in thermal spraying, we create a leading position in surface spraying with outstanding quality. By choosing Jinan Tianmeng Technology Co., LTD., you will enjoy high-quality repair services and a good user experience. We look forward to cooperating with you to jointly safeguard your equipment!

Contact Us

- Jinan Tianmen New Material Technology Co., Ltd

- Contact nameXue Yunling Chat Now

Product Categories

| Surface Treatment |

New Products

-

Surface repair of the mechanical industry, multi section roller, supersonic spraying processing, tungsten carbide coating, wear-resistant and anti-corrosion

-

Boiler surface repair and spraying of nano ceramic coating for anti-corrosion and wear prevention

-

Support customized mechanical sliding rails for laser melting surface repair, anti-corrosion and wear-resistant

-

Ceramic coating scraper, coating scraper, paper coating roller and other mechanical scraper products

-

Surface repair and aluminum spraying treatment process for mechanical valves in the source factory

-

Roller surface repair using spray welding process NI60 coating wear-resistant and anti-corrosion preparation

-

Mechanical industry supersonic spray machining spiral shaft surface repair, spraying anti-corrosion and wear-resistant coating

-

The surface repair of stainless steel plates by the manufacturer adopts arc spraying process LX88A coating, which is super hard and wear-resistant

-

Surface repair of stainless steel plates in the mechanical industry, arc spraying, wear resistance and corrosion resistance

-

Thermal spraying processing hopper surface repair Spraying tungsten carbide coating for anti-corrosion and wear resistance, with a wide range of applications

-

Thermal spraying processing hopper surface repair Arc spraying anti-corrosion and wear-resistant with a wide range of applications

-

Teflon coated coated steel products coating hardness can be adjusted packaging anti-collision

-

Arc spraying repair of GP-99 coating on the surface of Tianmeng roller with anti-corrosion and wear-resistant adjustable coating hardness

-

Metal surface treatment, thermal spraying, tungsten carbide processing, anti-corrosion and wear-resistant for Tianmeng wind cap disk

-

Tianmeng plasma spraying ceramic anti-corrosion, wear-resistant and anti-collision packaging with adjustablehardness

-

Anti corrosion construction of oil pipeline in the oil torch tower of Petro Pak Oil Company

-

Tianmeng Thermal Spray Processing Supersonic Spray Anti corrosion and Wear Resistant Coating

-

Tianmeng Hot Spray Processing Hot Spray Aluminum Process Wear resistant and Anti corrosion Surface Treatment Adjustable Hardness

-

Tianmeng Thermal Spray Processing Surface Repair Teflon Coating Processing Anti corrosion and Wear Resistance

-

Tianmeng wear-resistant sleeve thermal spraying processing supersonic spraying anti-corrosion and wear-resistant preparation

-

Preparation of anti-corrosion and wear-resistant ceramic coating by plasma spraying on the surface of Tianmeng shell

-

Heavenly Alliance Reactor Supersonic Spray Processing Anti corrosion and Wear Resistant Hard Coating Optional

-

Mirror drying cylinder spray enhanced supersonic thermal spraying tungsten carbide anti-corrosion and wear-resistant coating

-

Tianmeng tungsten carbide coating, supersonic spraying processing coating, anti-corrosion, wear-resistant, hardness adjustable, anti-collision

Popular Searches

Recommended Products

- Best Seller High Speed Laser Cleaning Machine 800W 1200w 1500W 2000W Laser Head Air Cooling Stainless Material Used

- Hand Held Laser Cleaner 1500W Continuous Laser Cleaning Machine Metal Rust Cleaning 2000W 3000W

- Pulse Fiber Laser Cleaning for Metal Surface Laser Cleaner 50W 100W Mini Pulsed Portable Laser Rust Remover Machine Price

- 100W Portable Laser Cleaner for Rust and Paint Removal, Trade Laser Rust Remover Device

- Industrial 200w 300w 500w 1000w Pulse Laser Cleaning Machine with Water Cooling for Coin Restoration

- Laser Cleaning Machine Rust Removal 200W Suitcase Pulse Handheld Fiber Laser Cleaner

- Best Seller High Speed Laser Cleaning Machine 800W 1200w 1500W 2000W Laser Head Air Cooling Stainless Material Used

- Portable Fiber Laser Cleaning Machine Backpack Design for Rust Paint Oil Removal Air Cooling-Good Price Stainless Steel

- Portable 100w 200W 300w Pulsed Small Size Air Cooling Fiber Laser Cleaner for Wood Brick Stone Removal

- Waste Car Radiator Crushing Separating Machine Scrap AC Radiator Recycle Machine

- Commercial Aluminum Cans Crusher Steel Crushing Recycling Machine

- Metal Scrap Crusher Iron Scrap Crushing Machine Metal Hammer Mill

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Xue Yunling

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Xue Yunling

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile