- Guangdong Derui testing equipment Co., Ltd

-

Dongguan, Guangdong, China

- Main products: Aging Test Chamber, Temperature and Humidity Test Chamber, High and Low Temperature Circulatory Test Chamber, Rapid Temperature Change Test Chamber, Saline Water Spray Tester, Packaging and transportation Tester, Vibration Tester, Tensile Tester, Furniture tester

Home > Products > Test equipment for cartons and packages > Dual-Specimen Friction Tester - Simultaneous Static & Dynamic Testing

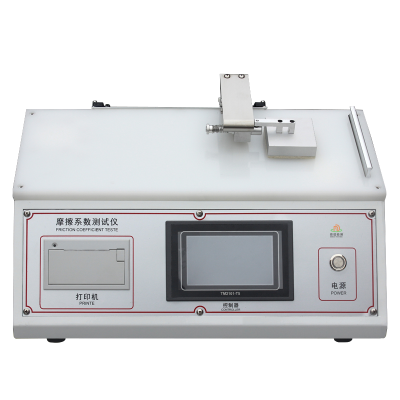

Dual-Specimen Friction Tester - Simultaneous Static & Dynamic Testing

- shenzhen

- T/T

- 7 days

You May Like

-

Automotive Humidity Environmental Chamber - ISO 16750-4 & LV 124 Compliance

-

Electronic Component Humidity Chamber - IPC/JEDEC J-STD-020 Moisture Sensitivity

-

Battery Humidity Chamber - ISO 23274 Cycle Life Simulation

-

IEC 60068-2-78 Humidity Chamber - Combined Temperature/Humidity Testing

-

Humidity Environmental Tester hamber - Material Endurance

-

High-Humidity Environmental Chamber - 98%RH Dew Point Control

Product Details

| Brand Name | Derui | Place of Origin | China | |

| Model Number | DR-B235 | Power | Other, 220V | |

| Usage | Other |

Product Description

Dynamic coefficient of friction tester Technical parameters

Test range | 0.01~10N, accuracy: 0.01N |

Thickness of the specimen | ≤0.2mm |

Slider size | 63*63mm |

Slider mass | 200±2g |

Test stable size | 170*225mm |

Slider velocity | 100±10mm/mim |

Slider stroke | 0~150mm(adjustable) |

Force range | 0~5N |

Size | 500*335*220mm |

Power supply | AC 220 50Hz |

Weight | 22kg |

Application Scenarios and Test Methods of Coefficient of Friction Tester

Application Scenarios

Coefficient of Friction testers are widely used in many industries to evaluate the friction properties of various materials. Below are some common application scenarios:

Plastic Film and Sheet

Application Scenarios: Packaging materials, food films, protective films for electronic products, etc.

Test standard: GB/T 10006, ASTM D1894, ISO 8295, etc.

Test Methods: Plastic film is fixed on the test bench, another part is fixed on the slider, and the friction force during sliding is measured by the sensor to calculate the static friction coefficient and dynamic friction coefficient.

Paper and Cardboard

Application Scenario: Printing paper, packaging cardboard, label paper, etc.

Test standard: GB/T 10006, TAPPI T816, etc.

Test Methods: Fix the paper on the test bench and the other part on the slider, measure the friction force during sliding through the sensor and calculate the static and dynamic friction coefficients.

Rubber and Elastomer

Application Scenario: Tires, rubber products, seals, etc.

Test standard: GB/T 10006, ASTM D1894, etc.

Test Methods: The rubber products are fixed on the test bench and the other part is fixed on the slider, the friction force in the sliding process is measured by the sensor, and the static friction coefficient and dynamic friction coefficient are calculated.

Metallic Materials

Application Scenario: Mechanical parts, metal plates, metal wires, etc.

Test standard: GB/T 10006, ASTM D1894, etc.

Test Methods: The metal material is fixed on the test bench, and the other part is fixed on the slider, and the friction force during sliding is measured by the sensor to calculate the static friction coefficient and dynamic friction coefficient.

Textiles and Fibers

Application Scenario: Clothing fabrics, industrial fabrics, ropes, etc.

Test standard: GB/T 10006, ASTM D1894, etc.

Test Methods: Fix the textile on the test bench and the other part on the slider, measure the friction force during sliding through the sensor and calculate the static friction coefficient and dynamic friction coefficient.

Coating and surface treatment materials

Application scenarios: automotive coatings, metal surface coatings, plastic surface treatment, etc.

Test standard: GB/T 10006, ASTM D1894, etc.

Testing method: Fix the coating material on the test bench and the other part on the slider, measure the friction force during sliding through the sensor and calculate the static friction coefficient and dynamic friction coefficient.

Medical Instruments

Application Scenario: Surgical instruments, implants, medical consumables, etc.

Test standard: GB/T 10006, ASTM D1894, etc.

Test Methods: The medical device material is fixed on the test bench and the other part is fixed on the slider, the friction force in the sliding process is measured by the sensor, and the static friction coefficient and dynamic friction coefficient are calculated.

Test Method

Preparation

Check the instrument: Make sure the power connection of the friction coefficient tester is stable, check the integrity of all components, especially the measurement sensor and the drive system. Make sure that there is no damage or abnormality in the equipment.

Clean the instrument: Clean the working surface of the friction tester to ensure that there is no oil, dust and other impurities.

Prepare the specimen: Select the appropriate specimen material according to the test requirements. The specimen should be flat and clean to avoid dust or oil to affect the measurement of friction.

Prepare calibration tools: Prepare standard weights, standard friction plates, calibration certificates and other necessary calibration tools and documents.

Specimen Installation

Fixing the specimen: Fix a specimen with the test surface upward and flat on the horizontal test bench. The specimen should be parallel to the length of the test bench.

Mounting the slider: Place the other specimen with the test surface down, wrap it around the slider, and secure the specimen with adhesive tape on the front and upper surfaces of the slider.

Placement of the slider: Place the fixed specimen slider in the center of the first specimen without impact, and make the test direction of the two specimens parallel to the direction of the slider and the force measurement system is not subject to force.

Setting test parameters

Setting parameters: In the control panel of the tester, set the relevant parameters, such as load, speed, test time, etc. These parameters need to be set according to the actual test requirements. These parameters need to be adjusted according to the actual test requirements to ensure compliance with the experimental design specifications.

Calibrate the instrument: Before testing, the equipment needs to be calibrated to ensure the accuracy of the measurement results. The calibration process includes adjusting the level of the frame, setting the test speed, calibrating the mass of the slider and other steps.

Execute the test

Start the test: After confirming that all settings are correct, start the friction tester and begin the testing process. During the test, the instrument will automatically record the friction force, displacement and time data, and calculate the friction coefficient through the algorithm.

Record data: During the test, the instrument will automatically generate a data report, the operator needs to check the accuracy of the data, and analyze and summarize as needed. When recording the results, be sure to save all the original data for subsequent verification and review.

Data Analysis and Report Generation

Calculate Friction Coefficient: The formula for calculating the friction coefficient is usually the ratio of friction force to positive pressure. [...] [...]

Solution: This may be due to improper sample installation or changes in the testing environment. Recalibrate the instrument, make sure all parameters are set accurately, and adjust the temperature and humidity of the experimental environment if necessary to reduce the interference of external factors.

Contact Us

- Guangdong Derui testing equipment Co., Ltd

- Contact nameLI Chat Now

- AddressRoom 113, 1st Floor, No. 3, Shugang Avenue, Hongmei Town, Dongguan, Guangdong

Product Categories

| ENVIRONMENTAL TEST CHAMBER | UNIVERSAL TEST EQUIPMENT | FURNITURE TEST EQUIPMENT | PAPER PACKAGING TEST EQUIPMENT |

| Test equipment for cartons and packages |

New Products

-

Low-Temperature Humidity Chamber - -40℃ to +150℃ Temperature Range

-

Three-Zone Humidity Chamber - Independent Temperature/Humidity Control

-

Fast-Response Humidity Tester - 5%RH/min Humidity Change Rate

-

Automotive Electronics Humidity Chamber - GM 9537P Humidity Testing

-

Automotive Electronics Humidity Chamber - GM 9537P Humidity Testing

-

CE UL Listed Vertical Combustion Tester for Plastics & Electronics

-

ASTM D635 Vertical Combustion Tester with Data Logging Function

-

IEC 60695 Vertical Combustion Tester for Electrical Components

-

UL 94 V-0 Vertical Combustion Tester for Flame Retardant Materials

-

ISO 1210 Vertical Combustion Tester for Textile Flame Resistance

-

EN 60335 Vertical Combustion Tester for Household Appliance Safety

-

UL 1581 Vertical Combustion Tester for Wire & Cable Insulation

-

Vertical Combustion Tester for Automotive Interior Materials Testing

-

Vertical Combustion Tester for Furniture Upholstery Flame Resistance

-

Vertical Combustion Tester for Children's Toy Safety Compliance

-

Vertical Combustion Tester 100mm×100mm Sample Size for IEC 60695

-

Vertical Combustion Tester CE Marked for EU Market Compliance

-

Vertical Combustion Tester for Silicone Rubber Flammability

-

Vertical Combustion Tester with PLC Control System

-

CE ISO 17025 Certified Image Measuring Instrument for Precision Metrology

-

Image Measuring Instrument for PCB Circuit Board Inspection

-

Image Measuring Instrument for Automotive Component Dimensional Control

-

Image Measuring Instrument for Aerospace Composite Material Analysis

-

Image Measuring Instrument for Aerospace Composite Material Analysis

Popular Searches

- digital tester

- resistance tester

- electrical instrument

- test instrument

- lab equipment

- analysis instrument

- laboratory instrument

- asphalt mixture mixer

- launch x431 master

- x431

- gloss meter

- resistance meter

- digital instrument

- dc load bank

- testing equipment

- testing machine

- battery load bank

- circuit tester

- impact tester

- lab instrument

- weather station

- gps receiver

- test equipment

- laboratory equipment

- electronic timer

- electronic meter

- electronic instrument

- electricity meter

- data collector

- experiment apparatu

Recommended Products

- Automatic sampler Introduction of Bamtone/S275 products

- UL94 Horizontal Vertical Combustion Chamber | Flammability Test Equipment for Cable and Plastic

- Horizontal Vertical Burning Tester | UL94 Fire Resistance Test Equipment for Polymers

- UL94 HB V-0 Horizontal Vertical Flame Tester | Flammability Resistance Testing Equipment

- Horizontal Vertical Flammability Testing Machine | UL 94 Standard Combustion Test Chamber

- UL94 Horizontal Vertical Burning Test Apparatus | Plastic Material Flame Spread Tester

- Horizontal Vertical Combustion Tester | UL94 Flammability Testing Apparatus for Insulating Materials

- UL94 Horizontal Vertical Flame Chamber | Fire Resistance Tester for Plastic and Rubber Materials

- Horizontal Vertical Burning Test Machine | Polymer Flame Resistance Testing Equipment

- Horizontal Vertical Flammability Tester | UL 94 HB V-0 V-1 V-2 Combustion Test Chamber

- UL94 Horizontal Vertical Burning Tester | Flammability Test Equipment for Plastics

- Electromechanical Computerized Universal Tensile Strength Testing Machine with Large Deformation Extensometer

Find Similar Products By Category

- Instruments & Meters > Test Instrument > Test Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

LI

Hi there! Welcome to my shop. Let me know if you have any questions.

LI

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile