Home > Products > Welding Wire > High-Performance CO2 Wear-Resistant Welding Wires for Roller Press Machines

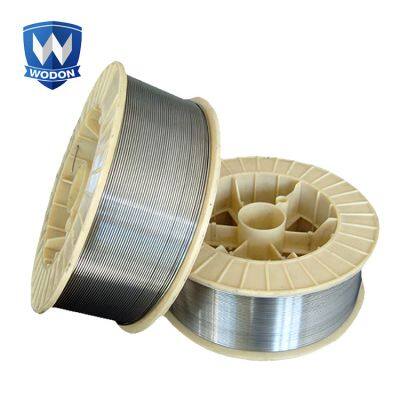

High-Performance CO2 Wear-Resistant Welding Wires for Roller Press Machines

- 100000 Kilogram / Kilograms per Month

- shanghai

- T/T L/C

- 14 days

You May Like

-

Roller surface surfacing welding wear-resistant welding wire

-

Surfacing cold-rolled backup roll wear-resistant welding wire

-

Welding wire for the wear-resistant layer of vertical mill roller sleeve

-

Wear-resistant lining plate for the inner part of the mining feeding chute

-

Chromium Carbide Overlay Wear - Resistant Plate

-

Chromium Carbide Wear Plates for Cement Industry High Abrasion Resistance Custom Sizes Available

Product Details

| Brand Name | WODON | Place of Origin | China | |

| Model Number | D161 | Material | Nickel / Nickel Alloy | |

| Diameter | 2.4 2.8 3.2mm | Weight | 15 kg/coil, Vacuum packing without the joint | |

| Application | Hot rolling roller surfacing welding | Melting Point | 1538-3000℃ | |

| Flux Content | trace |

Product Description

Welding Wires

Smooth Surface

No Clearing Slag

Low Welding Spatter

High Welding Efficiency

High Transition Coefficient--0.9

Model | Specification (mm) | Hardness (HRC) | Main Ingredient | Main Application |

WD161 | 2.4 2.8 3.2 | 58-65 | C:3.0-5.0 Cr:22-27 | Used for wear plate single layer hardfacing, hardness is up to HRC60 after welding. |

WD261 | 2.4 2.8 3.2 | 57-63 | C:3.0-5.0 Cr:22-27 | Used for wear plate double layer hardfacing, hardness is above HRC60 after welding,good impact resistance and not easy to fall off. |

WD361 | 2.4 2.8 3.2 | 57-63 | C:3.0-5.0 Cr:24-30 | Used for wear plate multi-layer hardfacing, hardness is above HRC60 after welding,good impact resistance and not easy to fall off. |

WD181 | 2.4 2.8 3.2 | 58-65 | C:3.0-5.0 Cr:22-27 | Used for thin sheet welding, hardness up to HRC60 after welding, control overlay thickness below 3mm to ensure good wear resistance. |

WD161H | 2.4 2.8 3.2 | 58-65 | C:3.0-5.0 Cr:25-32 | Overlay has high chromium content after welding, good wear resistance. Used for wear plate single layer hardfacing. |

Workshop

4 welding wires production lines9,000 tons output per year

Packaging & Delivery

1. Welding wire 15kgs vacuum packaging 2. Welding wire 50kgs packaging 3. Welding wire 150-250kgs per drum

Why us?

Wodon produces more than 100 kinds of flux cored welding wires | |

Products | Details |

Wear plate welding wire | Single-layer hardfacing welding wire, double-layer hardfacing welding wire and multi-layer hardfacing wire |

Welding wire for repairing | Coal grinding roller hardfacing welding wire; cement Vertical mill hardfacing welding wire; Squeeze roller hardfacing welding wire; Repairing welding wire for steel slag grinding roller; Repairing welding wire for star wheel and other repairing welding wire |

Gas shielding welding wire | All kinds of gas shielding repairing welding wires (repair all kinds of wear resistant parts), heat resistant welding wire, grate bar and single tooth roller repairing welding wire, impact resistant welding wire and various welding wires containing special elements (which can be customized as required) |

Instruction | 1. Smooth wire feeding, stable arc, uniform diameter 2. Less spatter and smoke during welding, above 90% hardfacing efficiency 3. Every drum (spool) packed with one whole PC of welding wires, without any joint, no broken arc phenomena during the welding to improve production efficiency 4. Developing more than 100 kinds of flux cored wear resistant welding wire suited to metal wear resistant field which can satisfy the wear resistant requirements of many wear resistant parts under all kinds of working conditions 5. The base metal and the wear resistant overlay are metallurgical bonding; After welding, the wear resistant layer doesn't fall off because of uniform stress relief. We can provide qualification certificate, product data sheet, test report including chemical composition, hardness, etc of wear resistant overlay |

We developed our own flux cored welding wire with customized ingredient for all kinds of working conditions. Our welding wires has following advantages:

1. smooth wire feeding, stable arc , uniform diameter

2. less patter and smoke during welding, above 90% hardfacing efficiency

3. every drum packed with one whole PC of welding wires, without any joint, no broken arc phenomena during the welding to improve production efficiency

4. developing more than 100 kinds of flux cored wear resistant requirements of many wear resistant field which can satify the wear resistant requirements of many wear resistant parts under all kinds of working conditions.

5. the base metal and the wear resistant overlay are metallurgical bonding; after welding, the wear resistant layer doesn't fall off because of uniform stress relief.

FAQ

Q: Are you trading company or manufacturer ?

A: We are ISO certified flux cored welding wire and CCO wear plate factory.

Q: Are you able to produce customized chemical composition and dimension?

A: Yes, we could offer special welding wire and wear plate according customers' requirement.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge.

A: Payment

Q: Do you provide after-sales service ?A: Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Contact Us

- Tianjin Wodon Wear Resistant Material Co., Ltd

- Contact nameding Chat Now

Product Categories

| wear plate | Wear Components | Welding Wire |

New Products

-

hardfacing welding CCO bimetallic wear resistant steel plates

-

Chute Plates: High-Performance Wear-Resistant Solutions for Industrial Chutes

-

High-Quality Wear-Resistant Chute Plates for Mining and Bulk Material Handling Industries

-

Chutes and Chute Liners with 400°C Temperature Endurance

-

Premium Chromium Carbide Overlay Cladding Hardfacing Wear Plate for Industrial Durability

-

bimetallic wearable lining plate bucket excavator Customizable Bimetallic Wearable Lining Plates

-

Customizable Wear-Resistant Lining Plates Tailored to Excavator Buckets

-

High-Chromium Bimetallic Wear-Resistant Steel Plates for Mining Machinery: Unrivalled Durability

-

Wodon Chromium Wear Resistant Steel Plates for Iron Ore Mill Feeder Conveyor Wear Liners

-

Ultra-Durable Excavator Wear-Resistant Edge Plates - Engineered for Exceptional Performance

-

Top-Quality Wear-Resistant Plate for Excavator Bucket Mouth - Unbeatable Durability and Performance

-

The Hardest and Most Durable Alloy Wear Plate & Blade for Excavators - Unsurpassed Resistance

-

Heavy-Duty Grab Bucket Liners for Port Handling: Enduring Massive Ore Loading Stress

-

Crusher’s Tough Shield in Mining: Top Wear Liners for Efficient Crushing

-

Ball Mill’s Power Armor in Mines: Super Wear Liners for Great Grinding

-

Cement Mill’s Key Liner in Building: Excel Wear Liners for Quality Grinding

-

Mixer’s Durable Engine in Concrete: Quality Liners for Strong Mixing

-

Pulverizer’s Guardian Wall in Power: Reliable Liners for Steady Coal Powder Outpu

-

Ash Removal System’s Anti-Wear Pioneer in Power: Durable Liners for Smooth Ash Cleaning

-

Blast Furnace’s Heat-Resistant Armor in Metallurgy: Tough Liners for Steelmaking Lifeline

-

Conveyor Transfer Point’s Smooth Guard in Port: Quality Liners for Unblocked Material Flow

-

Port Conveyor Transfer Wear Liner: Material Flow Smoothie

-

Port Grab Bucket Wear Liner: Loading Tough Protector

-

Metallurgy Rolling Mill Wear Liner: Precision Rolling Assistant

Popular Searches

- Aluminum Welding Wire

- Alloy Welding Wire

- mig welding

- welding solder

- solder

- Solder Wire

- Welding Cable

- Steel Welding Wire

- Spool Wire

- Welding Wire

- Co2 Welding Wire

- Copper Welding Wire

- Gas Welding Wire

- welding material

- welding consumables

- h08a

- mig wire

- Welding Wire Rod

- Welding Wires

- lead solder

- Mig Welding Wire

- Er 70s 6 Welding Wire

- Submerged Arc Welding Wire

- Copper Coated Welding Wire

- Solid Welding Wire

- Tig Welding Wire

- Co2 Gas Shielded Welding Wire

- gas shielded

- cobalt wire

- solid wire solder

Recommended Products

- Hardfacing Techniques & Features

- Hardfacing Applications in Various Industries

- Materials & Consumables for Hardfacing

- hard surface welding wire

- automated cladding

- wear plate manufacturers

- CO2 MIG Welding Wire Aws A5.18 Er70s-6 Argon Arc Welding Wire

- Welding wire for the wear-resistant layer of vertical mill roller sleeve

- Surfacing cold-rolled backup roll wear-resistant welding wire

- Roller surface surfacing welding wear-resistant welding wire

- Durable Flux-Cored Wear-Resistant Welding Wires for Grinding Rollers

- High-Performance Hardfacing Wear-Resistant Welding Wires for Single-Tooth Rollers

Find Similar Products By Category

- Industrial Equipment & Components > Welding & Soldering Supplies > Welding Wire

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

ding

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

ding

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile