Home > Products > Pipe Spool Prefabrication > ASME B16.9 SS304 316 2205 inconel incoloy Pipe spoon Prefabrication ASTM JIS En Standard Stainless Steel Pipe Tube Prefabrication

ASME B16.9 SS304 316 2205 inconel incoloy Pipe spoon Prefabrication ASTM JIS En Standard Stainless Steel Pipe Tube Prefabrication

- 5000 Piece / Pieces per Month

- shanghai

- T/T L/C Cash

You May Like

-

ASME B 31.3austenic hastelloy inconel incoloy SS pipe weld with flange pipe spool fabrication service

-

ASME B16.9 pipe spoon Prefabrication austenic hastelloy inconel incoloy industrial pipeline Piping Systems welding service

-

ASME B31.3 Customized spool flange-flange stainless steel pipe fabrication 10\" blind flange spool end pipe spool prefabrication service

-

ASME B16.9 Customized spool flange-flange stainless steel pipe prefabrication fittings flange spool pipe spool prefabrication service

-

Stainless steel Customized Pre-Fabrication of Piping spools stainless pipe spool prefabrication service

-

Exotic Inconel Incoloy Hastelloy Duplex Superduplex Stainless Steel Pipe or Tube

Product Details

| Brand Name | Qunrong | Place of Origin | China | |

| Model Number | QR-001 | Certification | ISO | |

| Thickness | 40mm | Type | Seamless | |

| Application | on the site installation | Standard | ASTM, AISI, JIS | |

| Outer Diameter | 1500mm | Welding Line Type | EFW | |

| Steel Grade | 300 Series |

Product Description

What Is Pipe Fabrication?

Pipe Fabrication is the manufacture of straight lengths of metallic pipe and piping components, which include wrought or forged elbows, tee and reducer fittings, forged flanges, and the pipe itself, to provide a simple or complex piping systems to safely transport or process liquids, gases, and solids.

Pipe fabrication plays a critical part of our society’s infrastructure, ensuring the commercial, institutional, and industrial facilities we rely on and work in, are safely designed, mechanically correct, and thoroughly tested or examined for the service the piping system was designed for. The fabrication of piping typically includes cutting, beveling, welding, and bending (or other pipe forming operations); and is performed by skilled tradespeople.

Pipe fabrication demands a high level of precision among hundreds of components with equally challenging assembly and installation processes. In any construction project where a network of piping is involved, pipe fabrication requires comprehensive planning, scheduling, and execution according to the design, location, timing, and budget requirements. In this blog, we’re breaking down all these moving parts, looking at the tools, equipment, planning, and other requirements that go into each step of the process.

Where Does Pipe Fabrication Take Place?

Some projects call for a field construction solution. Whether it’s more efficient, effective, or appropriate to fabricate pipe in the shop or on-site depends first and foremost on the size and scope of the project, but is influenced by numerous factors, including:

The weather

The pipe material and dimensions

Accessibility and safety concerns

Availability of on-site support personnel

Required welding facilities and resources

Scheduling and collaboration with other trades

If the project is for new or existing piping systems

Environmental and quality control needs

While piping can be fabricated in the field close to the pipe installation job site, for the purpose of this blog, we’re focusing on projects where the pipe fabrication is performed in a workshop and then transported to the job site for final installation. Pipe fabricators typically have a productive workshop facility to handle projects of various sizes. A purpose-built workshop that protects the worker and the work from the elements along with efficient machinery and equipment, and a skilled craft workforce makes Shop Fabrication the ideal response for most piping projects.

The Pipe Fabrication Process

Pipe fabrication is a detailed process from beginning to end. All engineering information, such as drawings, inspection and testing requirements, and applicable codes and standards related to the project, are all contained in a document called the Pipe Fabrication Specification. All pipes and their fittings must be manufactured and assembled according to the spool drawings in the pipe fabrication specifications. It’s also vital for pipe fabricators to consider the size of the assembly for transportation purposes. Subassemblies are often helpful in separating large projects into more manageable elements when moving between the shop and the project site.

Once the Pipe Fabrication Specification is solidified, the pipe fabrication process looks like this:

Marking: Pipe materials are marked and verified according to the Pipe Fabrication Specification.

Tagging: Pipe materials are tagged using a stamp or paint to ensure pipe heat numbers are displayed on all sections before cutting.

Cutting: Pipe cutting methods, such as a saws, gas torch, grinding, or plasma cutting, are chosen according to the type of steel or other metal in use.

End preparation: Beveling and fit-ups are completed following an approved specification and WPS.

Welding: Pipe welding planning ensures all seams will be positioned and aligned correctly in the final assembly.

Pipe and Fitting Welding: Pipes and fittings are supported and secured for a fit-up inspection. If passed, the joints are welded.

Details Marking: Various identifying details of the piping system, inspection details and signature, and welding date are marked near joints. The pipe spool number is marked with a paint marker and aluminum tag.

Heat Treatment: Preheating and PWHT may be completed depending on project requirements.

Inspection: Non-destructive testing ensures that all steps of the fabrication process have been completed and meet or exceed the project requirement and regulations. Piping that passes is released for painting or construction. Piping that does not pass must be repaired and reinspected. Piping that is to be painted will require another inspection prior to being released for construction.

Pipe Spool Fabrication

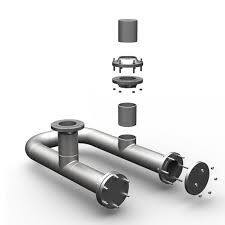

A piping system consists of prefabricated components; these components are called pipe spools. Pipe spools include pipes, flanges, fittings, elbows, tees, etc. Pipe spools connect long pipes with flanges at the ends so they can be attached to another pipe with a matching flange.

Refineries, power plants, oil & gas production facilities, and petrochemical plants require intensive piping as the pipes are used to transport fluid and gas. Pipe spools are therefore suitable for these industries.

Pipe spools are manufactured using raw pipe and pipe fittings. The raw pipes are cut to pre-defined dimensions suitable for the pipe fittings and other components. They are generally manufactured in the fabrication shop by following a series of cutting, beveling, welding, and other processes depending on the design and requirements. Pipe spool fabrication is a critical stage not only for piping but also in an overall industrial construction project. Assembly needs to be done precisely; there is no room for mistakes.

Pipe Fabrication Tools and Equipment

Pipe fabricators rely on a wide range of specialized equipment to get their jobs done safely and efficiently. Most pipe fabrication equipment designed to handle medium- to large-scale projects is intended for use only in the workshop where there’s appropriate space, protection from the weather, reliable security, and quality control complete quality control capabilities.

However, many pipe fabrication tasks for small-volume projects or those with strict freight limitations may also be completed in the field. Regardless of where the work takes place, here are some of the key tools that allow pipe fabricators to create the countless complex precision piping systems that surround us.

Saws and Thermal Cutting Equipment

Rotating Equipment

Pipe End Finishers

Welding Machines & Equipment

Pipe Benders

Pipe Fit-Up Tools

Pipe Flangers

Rigging & Transportation Equipment

Pipe Jacks

Fork Lifts

Contact Us

- Shanghai Qunrong Industrial and Trade Co.LTD

- Contact nameConrad Chat Now

- AddressBaoshan district

Product Categories

| High pressure fittings&adapters | Stainless Steel&Nickel Pipe Tube | S.S Nickel Pipe Fittings&Flange | S.S Nickel Alloy Wire&Ring Sleeve |

| Pipe Spool Prefabrication |

New Products

-

Exotic Inconel Incoloy Hastelloy Duplex Superduplex Stainless Steel Pipe or Tube bending R=5D 10D

-

ASTM high quality Exotic Inconel Incoloy Hastelloy Duplex Superduplex Stainless Steel Seamless/welded Pipe or Tube

-

High quality Exotic Inconel Incoloy Hastelloy Duplex Superduplex Stainless Steel Wire Coil

-

High quality Stainless Steel Wire Type 304 Wire Coil

-

High quality Stainless Steel Wire Type 316 Wire Coil

-

High quality Stainless Steel Wire Type 321 Wire Coil

-

High quality Nickel Alloys/ Monel Wire Inconel 600 Wire Coil

-

High quality Nickel Alloys/ Monel Wire Inconel X-750 UNS N07750Wire Coil

-

High quality Nickel Alloys/ Monel Wire Monel 400 UNS N04400 Wire Coil

-

sockolet price/weldolet/threadolet/swaged nipple/hex plug pipe socket welding pipe fittings socket weldolet

-

ANSI/ASME/GOST/DIN/JIS/BS Butt Weld Pipe Fitting Stainless/Alloy Seamless Steel elbow45/90/180 Degree Long/Short Radius Socket/Threaded/Reducing/Equal Elbow

-

ANSI/ASME/GOST/DIN/JIS/BS Butt Weld Pipe Fitting Stainless/Alloy Seamless Steel Factory Hot Sale Thread Stainless Steel Pipe Fittings Manufacturer OEM Elbow Tee Nipple Union

-

Stainless Steel Sanitary SS304 SS316L 90 Degree Bw Seamless Elbow Pipe Fittings

-

Sanitary Stainless Steel Pipe Fittings Tube Fittings/Elbow/Ferrule with 3A SS304 SS316L 90 Degree Bw Seamless Elbow Pipe Fittings

-

Stainless Steel Industrial OEM Corrosion Resistant Weld Stub End/Tee/Reducer/Cross/End Cap/Elbow Pipe-Fittings

-

B16.9 En10253 304 Butt Weld Ss SUS304 SUS316 Super Duplex 2205 Uns31803 Seamless Welding Cap Reducer Bend Pipe Fitting Tee Elbow Stainless Steel Pipe Fittings

-

Large Forged Pipe forged ring , Cylinder Forging, Sleeve and Spool

-

Professional Forging Hot Forging Parts Non-Standard Processing Mold Forged Sleeve Ring

-

Professional Forging Hot Forged Stainless Steel Ring Sleeve Stainless Steel Ring Forging Oem Customized Forging Ring

-

Professional Forging Hot Forged SS Ring Sleeve Super duplex Stainless Steel Ring Forging Oem Customized Forging Ring sleeve

-

Professional Forging Hot Forged SS Ring Sleeve Nickel alloy Titanium alloy Ring Forging Oem Customized Forging Ring sleeve

-

Professional Gear Ring Forged Ring Forging Forged Seamless Rolled Rings sleeve 42CrMo4 Forging Parts Forged Large Ring sleeve

-

ASTM nickel alloy supper alloy hastelloy C276/X/C-2000/G-35 Forged/Forging ring sleeve

-

ASME B31.3 B 16.5 Customized spool flange-flange SS/Nickel Alloy pipe fabrication elbow flange spool end pipe spool prefabrication

Popular Searches

- copper tube

- Copper Ingot

- copper clad aluminum

- non-ferrous metal

- Copper Alloy

- hpmc

- micro fiber

- heater tube

- portland cement

- rapid hardening cement

- Hydroxypropyl Methyl Cellulose

- Copper Bars

- copper coil

- copper sheet

- copper rod

- brass rod

- brass copper

- copper pipe

- copper cathode

- Copper Round Bar

- Brass Bar

- Copper Flat Bar

- Copper Rod Bar

- Brass Round Bar

- Copper Ingots

- copper plate

- Brass Ingot

- Copper Pipes

- copper tubing

- copper bar

Recommended Products

- Stainless Steel Pipe Micro Fine Tube for Industry

- Round Stainless Steel Pipe ASTM A270 A554 SS304 316L 316 310S 440 1.4301 321 904L 201 Square Pipe Inox Ss Seamless Tube

- ASTM A269 Tp316L 12.7X0.89 12.7X1.24 12.7X1.65 Bright Annealing Stainless Steel Seamless Tube

- The Best Price for Duplex Stainless Steel Seamless Heat Exchanger Annealed Tubes

- SUS304 Stainless Steel Pipe Stainless Steel Tube

- Good Quality SA-240/SB-688 Stainless Steel Sanitary Tube

- Industrial SA-240/SB-625 1.4539 Finish Stainless Steel Pipe Seamless

- Seamless steel pipe, special-shaped pipe, various plates

- steel pipe

- X60 line pipe

- Hot Dipped Galvanized Steel Pipe AISI ASTM Tp 201/304 /310/316/309S Thickness Seamless Steel Pipe and Tube

- 304/304L/316/316L Stainless Steel Pipe Welded Pipe Seamless Tube

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Pipe & Tube

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Conrad

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Conrad

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile