- Baoji Along filter equipment technology co., ltd

-

Baoji, Shaanxi, China

- Main products: stainless steel powder sintered filter cartridge, sintered titanium filter cartridge, stainless steel sintered filter disc, titanium sintered filter disc, metal sintered porous materials, titanium sintered filter, SS 316L sintered filter, micro porous bubble diffuser, sintered filter tube, stainless steel powder sintered filter plate, microporous metal aerator, sintered porous titanium plate

Home > Products > stainless steel sintered porous filter disc > 1-70um Stainless Steel Powder Sintered Sparger

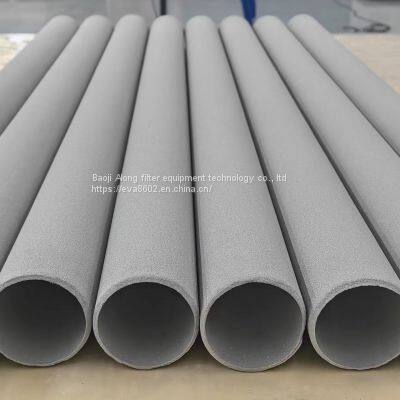

1-70um Stainless Steel Powder Sintered Sparger

- T/T L/C PayPal Other

You May Like

-

SS316L powder sintered filter sparger 1um 5um10um20um30um50um

-

Microporous Sintered Porous Titanium Plate As PTL For PEM Electrolyzer

-

70um Sintered Porous Transport Layer For PEM Electrolysis

-

PEMWE Sintered Porous Transport Layer

-

Sintered Porous Transport Layer (PTL) For PEM Electrolysis For Green Hydrogen

-

SS316L sintered porous sparger for bubble diffusion

Product Details

| Brand Name | Aong | Place of Origin | China | |

| After-sales Service Provided | Overseas service center available |

Product Description

1. Manufacturing Technique

Stainless steel 316L sintered porous material is stainless steel 304, 304L, 316, 316L powder as the raw material, after screening, molding, sintering microporous material.

Feature: Stainless steel sintered porous material has excellent corrosion resistance, oxidation resistance, wear-resistance and mechanical properties.

2. Specification of stainless steel sintered porous materials

| Material | Filter Rating | Porosity | Penetrability | Working pressure | Operating temperature | Shape | specific surface area |

| 304,304L,316, 316L Stainless steel powder | 0.5um-70um | 30-45% | 3-1300M3/M2hKPa | 3.0MPa | 600℃ | Round Disc, Sheet, Tube, Round Bar, cap. | 10-40cm2/cm3 |

| Production | (Diameter)Length | (Diameter)Width | Thickness | Customized |

| Sintered porous round discs | φ5-φ300mm | φ5-φ300mm | 0.5-10mm | Yes |

| Sintered porous sheets | 5-300mm | 5-300mm | 0.5-10mm | Yes |

| Sintered porous tubes | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

| Sintered porous cartridge | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

3. Properties of stainless steel sintered porous materials:

High-temperature resistance, in normal use under 500 ℃.

High mechanical strength, good plasticity, can be machined.

Corrosion resistance, oxidation resistance, can be used in nitric acid, sulfuric acid, dilute hydrochloric acid (5%), acetic acid, liquid hydrogen, liquid nitrogen environment.

Good molding process, according to customer drawings for processing a molding.

High filtration precision and good purification effect.

The pores are uniform, the internal structure is stable, and no particles fall off.

Good air permeability, easy to back blow cleaning, can be used repeatedly online regeneration.

Wear resistance and impact resistance, good mechanical properties.

4. Application of stainless steel sintered porous materials

According to its physical and structural characteristics, stainless steel sintered porous materials are mostly used in the fields of noise elimination, filtration and separation, fluid distribution, flow-limiting, capillary core and so on.

The chemical raw material production process in addition to impurity filtration, material decarburization filtration, and fine filtration.

Ultrafiltration, RO, EDI system security filtration in water treatment.

The food and beverage industry finished product clarification filtration.

Filtration and recovery of the precious metal catalyst in the petrochemical industry.

Precision filtration of liquid raw materials, products and pharmaceutical intermediates in the chemical industry.

Reverse osmosis security filtration in the field of water injection filtration.

Gas purification of steam, compressed air deoiling purification.

Medium purification and flow limitation for pneumatic components, lubricants, fuels, and hydraulic pressure systems.

Chemical dye industry of high - temperature decarburization.

5. Stainless steel sintered porous materials are allowed to use in the environment

Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, liquid hydrogen, liquid nitrogen, hydrogen sulfide, acetylene, hydrogen, carbon dioxide gas, water vapor, etc.

6. Precautions for the use of stainless steel sintered porous materials:

During installation, disassembly and clean avoid scratches, collisions and falls on hard objects.

When using, the filtrate is filtered from the outside in to avoid the reverse direction.

Avoid instant pressurization when the filter element works.

When the filtration efficiency is less than 50%, the filter element should be cleaned in time.

When cleaning the filter element, the first backflow with pure gas, backflow pressure is 1.5 times the working pressure, each time for 3-5 seconds, and 4-6 times, then backwash with clean liquid for 3-5 minutes, repeat 2-3 times.

If the filter element is not good after online back blowing and backwashing, it should be removed and cleaned in time.

7. Method for cleaning stainless steel sintered porous materials

The decarbonization filter elements in the pharmaceutical and chemical industries are mainly back blown and back washed, and the ultrasonic cleaning is the best.

The filter elements of the water industry are mainly rinsed with a 5% concentration of nitric acid.

According to the chemical properties of the filtered impurities, the filter elements of the original liquid shall be respectively soaked in pickling (5% nitric acid) or alkaline washing (3-5% sodium hydroxide) and then washed with ultrasonic cleaning.

Production Steps:

8. Main products list

Contact Us

- Baoji Along filter equipment technology co., ltd

- Contact nameEva Li Chat Now

- Phone86-187-00709012

- AddressQinganbao Industrial Park, Baoji, Shaanxi

Product Categories

New Products

-

Sintered Porous Titanium Plate As PTL For PEMWE

-

Chemical Filtration Stainless Steel Filter Microporous Sparger

-

Sintered Titaniun Plate As PTL For PEMWE Of H2 Production

-

5-70um metal powder sintered porous titanium plate for PEMWE

-

Pharmaceutical Filtration Sintered Porous Titanium Filter Plate(Tube)

-

Stainless steel sintered porous filter cartriges for filtration and purification

-

10um Sintered Porous Ti Plate For PEM Electrolytic cell

-

316L Powder Sintered porous sparger Microporous Bubble Diffuser

-

30um Sintered Porous Transport Layer For PEM Electrolysis

-

MEA Sintered Porous Titanium Plate Gas Diffusion Layer For PEMWE

-

10um Porous Titanium Transport Layer For PEM Electrolysis Cell

-

Titanium Powder Sintered porous sparger Steam Filtration

-

10um titanium porous transport layer plate for PEMWE

-

316L Sintered Porous Stainless Steel Filter Tubes For Filtration

-

Sintered Porous Titanium Plate for PEM Electrolyser

-

Sintered Porous Stainless Steel 316L Filter cartriges For Sparger

-

5-70um Ti Sintered Porous Transport Layer Plate For PEMWE

-

Sintered Porous Titanium Plate PEM Electrolysis For Hydrogen Production

-

10um Sintered Porous Ti Plate As PTL For PEMWE

-

5um 10um Sintered Ti PTL For PEM Electrolyzer

-

Sintered Titanium Porous transport Layer For PEM Electrolysis

-

10um Microporous Sintered Ti Transport Layer For PEM Electrolysis

-

10um Sintered Porous Titanium Plater For PEM Electrolyser

-

Sintered Porous Titanium Filter tubes

Popular Searches

- filter cartridge

- filter element

- wire cloth

- stainless steel wire mesh

- pipette tip

- wire mesh filter disc

- filter mesh

- plastic filter

- filter tube

- metal net

- wire mesh disc

- sintered wire mesh

- wire gauge

- stainless steel filter disc

- screen disc

- wire screen

- porous stainless steel

- sintered mesh disc

- filter disc mesh

- wire mesh disk

- stainless steel micron filter

- stainless steel porous filter

- filter element

- spur gear

- powder metallurgy part

- gear part

- sintered metal part

- powder metallurgy

- sintered part

- metal gear

Recommended Products

- Industrial water ionizer with 1000LPH/2000LPH/3000LPH/4000LPH

- Industrial water ionizer 1000LPH/2000LPH/3000LPH/4000LPH

- 9 /11 plates Water ionizer

- Alkaline Water Machine XQ-AKSO

- Water ionizer Machine XQ-AKSO

- Industrial /Commercial hydrogen alkaline water ionizing System 1000LPH/2000LPH/3000LPH/4000LPH

- Industrial hydrogen alkaline water ionizing System 1000LPH/2000LPH/3000LPH/4000LPH

- Industrial Alkaline water ionizer with 1000LPH/2000LPH/3000LPH/4000LPH

- AKSO water ionizer

- Alkaline water machine with 9 or 11 Plates plus UV Ray function + 3 filters built-in !

- Newest Alkaline water ionizer

- XQ Water Ionizer with 9 or 11 plates plus UV Ray function + 3 filters inside

Find Similar Products By Category

- Industrial Equipment & Components > Filtration Equipment & Parts > Industrial Water Filter

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Eva Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Eva Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile