Home > Products > sintered titanium product > 0.5Microns Sintered Porous Ti Plate for PEM Electrode

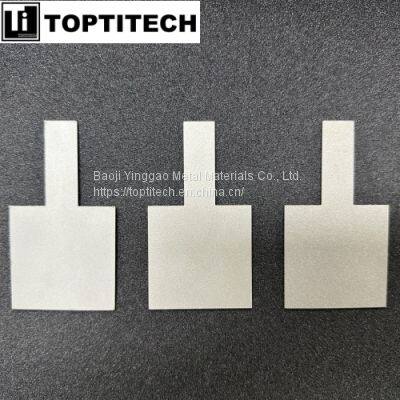

0.5Microns Sintered Porous Ti Plate for PEM Electrode

- Shanghai or Tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow

You May Like

Product Details

| Brand Name | TOPTITECH | Place of Origin | China |

Product Description

0.5Microns Sintered Porous Ti Plate for PEM Electrode

In PEM fuel cells, 0.5microns sintered porous Ti plate for PEM is commonly used as electrode materials for anodes and cathodes. It has high electrical conductivity and good chemical stability, and is suitable for the occurrence of electrode reactions.

0.5microns sintered porous Ti plate acts as both anode and cathode electrodes in PEM fuel cells. It provides the supporting structure of the catalyst layer and provides a conductive path for the oxidation reaction of hydrogen and the reduction reaction of oxygen, thereby realizing the electrochemical reaction of fuel and oxygen and generating electricity.

Parameters

Material: pure titanium powder

Technical: sintering and coating

Size:as drawing

Porosity:30-40%

Pore size:0.5microns

Advantages

High electrical conductivity: The sintered porous titanium plate has good electrical conductivity and can effectively conduct electrons. This is crucial for the electrode reaction to proceed, ensuring smooth transport of electrons between the anode and cathode.

High surface area: The porous structure of the sintered porous titanium plate provides a large amount of surface area, increasing the contact area with the catalyst reaction. This increases the reaction rate and enhances the efficiency of the electrochemical reaction between fuel and oxygen.

Good chemical stability: Sintered porous titanium plate has good chemical stability and can resist corrosion under acidic environment and high temperature conditions. This makes it work stably for a long time in PEM fuel cells.

Suitable for catalyst immobilization: The surface of sintered porous titanium plate can accommodate and immobilize catalysts, such as platinum or its alloys. This provides good catalytic activity and maintains catalyst stability and dispersibility.

Strong adaptability: The sintered porous titanium plate can be customized in shape and size according to needs, so as to adapt to fuel cell stack designs of different sizes and forms. It can also be used in combination with other materials to achieve better electrode performance.

Application

There are several commonly used materials that can be used in combination with sintered porous titanium plates to enhance electrode performance, the following are some of these common combinations:

Platinum Catalyst

Carbon materials

Oxide

Conductive polymers

Transition metal nitrides

Contact Us

- Baoji Yinggao Metal Materials Co., Ltd.

- Contact nameAna Chat Now

- Phone86-0917-3873009

- AddressWeibin, Baoji, Shaanxi

Product Categories

| porous titanium | Titanium Material | Titanium Process parts | Stainless Steel Sintered Production |

| Copper Sintering Material | sintered titanium product | other products |

New Products

-

Titanium Pipe for Exhaust and Downpipe

-

30nm Gold-Plated Porous Titanium Plate for PEM Electrolyzer

-

A 10 Micron Ultra-long Microporous Metal Titanium Plate

-

Titanium Plate With Flow Field For Electrolyzers

-

75um SS 304 Porous Wire Mesh Filter Cartridge

-

Porous Ti Elements for Temperature And Humidity Sensor Protection Cover

-

Porous Sintered Powder SS 316L Metal Plate Filter Semicircle

-

Custom Interface Stainless Steel Wire Mesh Filter Cartridge

-

Porous Titanium Sheet for Gas Diffusion Layer

-

30um Porous Metallic Filter Cartridge With DOE

-

Ultra-fine SUS316L Powder Sintered Filter Tube

-

Sintered Titanium Powder Filter Cartridges Rod Filter

-

Titanium Bipolar Plate for Battery Fuel Cells

-

Sintered Titanium Powder Porous Tube Filters for Liquid Filtration

-

65um M30 Connection Flat Bottom Porous Metallic Filter Element

-

M20 Connector Titanium Powder Sintered Filter Cartridge

-

Stainless steel Sintered Vents

-

D-1/8G Sintered Brass Air Exhaust Pneumatic Muffler Silencer

-

SUS 316L Micro Air Sparger And Brewing Diffuser Elements

-

0.2 Micron Porous Titanium Sheet for Filtration

-

10um Porous Titanium Plate With Chamfers for PEMFC

-

1.5mm Sintered Porous Titanium Plate Filtration Industry

-

10 Micron Porous Titanium Disc Filter Element

-

OD 150mm 20um Titanium Aeration Head for Ozone Sparger

Popular Searches

- Titanium Alloy

- titanium material

- medical instruments

- Stainless Steel Plate

- titanium tube

- titanium bar

- Locking Plate

- titanium sheet

- titanium foil

- titanium ring

- Heat Exchanger Plate

- titanium pipe

- titanium strip

- titanium alloy pipe

- Titanium Alloy Sheet

- Titanium Alloy Plate

- Bone Plate

- Steel Sheet Plate

- orthopedic plate

- Heat Transfer Plate

- orthopedic implants

- Titanium Locking Plate

- Titanium Anode Plate

- Orthopedic Locking Plate

- Titanium Sheet Plate

- Titanium Alloy

- titanium material

- medical instruments

- titanium tube

- titanium bar

Recommended Products

- Titanium Bipolar Plate for Battery Fuel Cells

- Sintered Nickel Fiber Paper Nickel Felt For GDL

- Ultra-thin 0.6mm Titanium Porous Transfer Layer for Hydrogen

- Nickel Mesh Anode in AEM Electrolyzer

- Pure Titanium Electrode Porous Fiber Felts For PEM Fuel Cell

- Hydrogen energy stack 3000W

- Hydrogen Bottles 5L,9L,12L

- Hydrogen Universal Controller

- Hydrogen energy stack 200W

- Hydrogen energy stack 500W

- Hydrogen energy stack 1000W

- Hydrogen energy stack 1500W

Find Similar Products By Category

- Electrical & Electronics > Battery, Storage Battery & Charger > Fuel Cell

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile