Home > Products > Stainless Steel Sintered Production > 0.22 Microns Sintered Stainless Steel Filter Ring

0.22 Microns Sintered Stainless Steel Filter Ring

- Shanghai or Tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow

You May Like

-

Versatile Monel Alloy Filter Plates Precision Filtration Needs

-

0.5Microns Sintered Porous Ti Plate for PEM Electrode

-

Platinum Coated Porous Titanium Sheets Electrodes For PEM Water Electrolyzer

-

5um Porous Inconel 600 Metal Filter Element

-

Titanium Micro Porous Flow Channel Plates

-

Nickel Fiber Felt for Electrolyzer GDL

Product Details

| Brand Name | TOPTITECH | Place of Origin | China |

Product Description

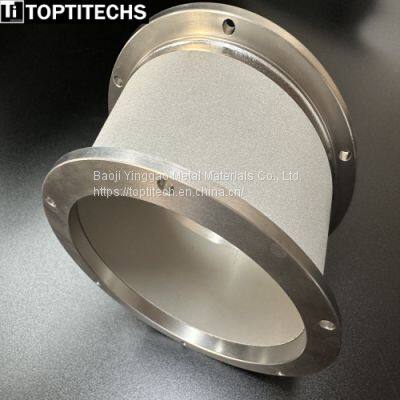

0.22 Microns Sintered Stainless Steel Filter Ring

Porous sintered metal filters are constructed from interconnected networks of uniformly distributed pores, creating intricate pathways that effectively capture solid particles present in gas or liquid flow streams. These filters are renowned for their exceptional mechanical strength and serve as outstanding depth filters. Type 316L stainless steel, known for its robustness, can endure temperatures up to 750°F (399°C) in oxidizing environments and 900°F (482°C) in reducing environments.

The production of sintered metal filters involves employing 316L stainless steel powder. The manufacturing process entails the uniaxial compaction of powder within a rigid tool possessing the inverse shape of the desired part, followed by sintering. By adjusting the compaction pressure and/or particle size of the powder, the pore size of the filter can be precisely controlled.

Specification:

Material: Pure stainless steel Powder

Porosity: 30% to 40%

Pore Size: 0.22 microns

Size: 150*80mm

Features

Durability: Stainless steel is known for its exceptional durability and resistance to corrosion, making filter rings made from this material highly robust and long-lasting. They can withstand harsh operating conditions, including high temperatures, pressure differentials, and exposure to corrosive chemicals, without compromising their structural integrity.

Chemical Compatibility: Stainless steel filter rings exhibit excellent chemical compatibility with a wide range of substances, including acids, alkalis, solvents, and organic compounds. This makes them suitable for filtration processes in diverse industries, such as chemicals, petrochemicals, pharmaceuticals, and food processing, where compatibility with various fluids is crucial.

High Filtration Efficiency: Stainless steel filter rings can achieve high filtration efficiency due to their uniform and controlled pore structures. They effectively trap and remove fine particles, contaminants, and impurities from liquids and gases, ensuring the desired level of cleanliness and purity in the filtered media.

Reusability: One significant advantage of stainless steel filter rings is their reusability. They can be easily cleaned through various methods such as backwashing, ultrasonic cleaning, or chemical cleaning, allowing for multiple uses and reducing replacement costs.

Temperature Resistance: Stainless steel filter rings can withstand high operating temperatures, typically up to 600 degrees Celsius. This attribute makes them suitable for applications involving hot liquids or gases, such as in the petrochemical and food processing industries.

Hygienic Properties: Stainless steel is a hygienic material commonly used in industries where cleanliness and sterility are paramount, such as the food and beverage and pharmaceutical industries. Stainless steel filter rings are easy to clean and maintain, ensuring adherence to strict hygiene standards and minimizing the risk of contamination.

Application:

Chemical Industry: The filter ring finds extensive use in the chemical industry for processes such as catalyst recovery, polymer filtration, and solvent purification.

Food and Beverage Industry: It is employed in the food and beverage industry for filtering liquids, including juices, syrups, and edible oils, ensuring product purity and quality.

Pharmaceutical Industry: The filter ring plays a critical role in pharmaceutical manufacturing, providing sterile filtration for drugs, vaccines, and other pharmaceutical products.

Petrochemical Industry: It is utilized in the petrochemical industry for the filtration of various fluids, including crude oil, refined petroleum products, and specialty chemicals.

Water Treatment: The filter ring is applied in water treatment systems, removing impurities, sediments, and particulate matter from water for both industrial and residential purposes.

Contact Us

- Baoji Yinggao Metal Materials Co., Ltd.

- Contact nameAna Chat Now

- Phone86-0917-3873009

- AddressWeibin, Baoji, Shaanxi

Product Categories

| porous titanium | Titanium Material | Titanium Process parts | Stainless Steel Sintered Production |

| Copper Sintering Material | sintered titanium product | other products |

New Products

-

4-layers Sintered Titanium Wire Mesh Filter Plate

-

Titanium Electrodes With Flow Channels

-

Titanium Pipe for Exhaust and Downpipe

-

30nm Gold-Plated Porous Titanium Plate for PEM Electrolyzer

-

A 10 Micron Ultra-long Microporous Metal Titanium Plate

-

Titanium Plate With Flow Field For Electrolyzers

-

75um SS 304 Porous Wire Mesh Filter Cartridge

-

Porous Ti Elements for Temperature And Humidity Sensor Protection Cover

-

Porous Sintered Powder SS 316L Metal Plate Filter Semicircle

-

Custom Interface Stainless Steel Wire Mesh Filter Cartridge

-

Porous Titanium Sheet for Gas Diffusion Layer

-

30um Porous Metallic Filter Cartridge With DOE

-

Ultra-fine SUS316L Powder Sintered Filter Tube

-

Sintered Titanium Powder Filter Cartridges Rod Filter

-

Titanium Bipolar Plate for Battery Fuel Cells

-

Sintered Titanium Powder Porous Tube Filters for Liquid Filtration

-

65um M30 Connection Flat Bottom Porous Metallic Filter Element

-

M20 Connector Titanium Powder Sintered Filter Cartridge

-

Stainless steel Sintered Vents

-

D-1/8G Sintered Brass Air Exhaust Pneumatic Muffler Silencer

-

SUS 316L Micro Air Sparger And Brewing Diffuser Elements

-

0.2 Micron Porous Titanium Sheet for Filtration

-

10um Porous Titanium Plate With Chamfers for PEMFC

-

1.5mm Sintered Porous Titanium Plate Filtration Industry

Popular Searches

- water treatment

- water purifier

- water filter

- filter cartridge

- air filter

- oil filter

- Filter Element

- wire mesh

- water filtration

- cartridge filter

- bag filter

- filter housing

- wire mesh filter

- Screen Filter

- filter mesh

- Sand Filter

- stainless steel strainer

- Coffee Filter

- Strainer Filter

- Y Strainer

- Candle Filter

- Mesh Filter

- filter valve

- sanitary filter

- sanitary strainer

- filter cylinder

- seal ring

- rubber ring

- O Ring Ring

- photographic

Recommended Products

- FX-850X40H small machine lubricating oil filter element

- LH1300R025BN3HC power plant fire-resistant oil outer protective net folding filter element, support customization

- MSF-04S-01 Fire-resistant oil fine filter element

- Replacement PALL filter element HC8900FKS26H \ Customized hydraulic oil filtration

- Replacement for PARKER filter element TXWL13-10 937863Q glass fiber, support customization

- Replace hydac filter element 0950R010BN3HC hydraulic oil and lubricating oil filter, support customization

- Replace Internormen filter element 01E.1201.25VG.10.S.P, support customization, processing according to drawings

- Replacement for PARKER horseshoe cover filter 937399Q 937394Q CST45003-03

- PH718-03-NB PH312-11-CG Customized filter element, replacing imported

- Replacement for HYDAC filter element 0110D010 BH4HC/V high pressure glass fiber filter material

- MKFA08 Dust collector filter square cylindrical vacuum cleaner dust collector air filter cartridge wooden frame filter element MKFSF10

- 931271 oil filter element CST45003 hydraulic oil filter FDBE1A10Q shield machine filter element

Find Similar Products By Category

- Industrial Equipment & Components > Filtration Equipment & Parts > Filter Element

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Ana

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile