Home > Products > metal product > Sintered Nickel Fiber Paper Nickel Felt For GDL

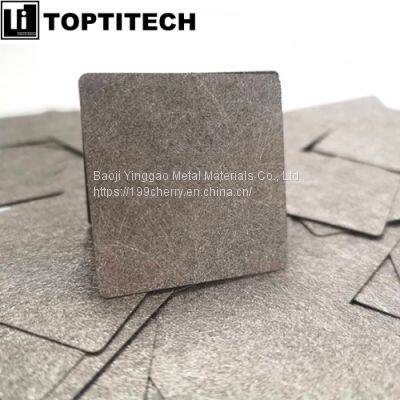

Sintered Nickel Fiber Paper Nickel Felt For GDL

- 1000000 Piece / Pieces per Month

- shanghai, shenzhen

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 10 days

You May Like

-

Sintered stainless steel filter cartridge cups

-

SS 316L Diffuser Stone For Ozone Generator Food Grade

-

Customized 0.5um Titanium Rod Filter Cartridge Special Interface

-

0.5mm Sintered porous titanium sheet Porous Transport Layers for PEM electrolyzers

-

Sintered conical wire mesh filter strainer

-

0.22 Microns Sintered Stainless Steel Filter Ring

Product Details

| Brand Name | TOPTITECH | Place of Origin | China | |

| Model Number | / | Type | Nickel Plate | |

| Application | PTL in pem | Ultimate Strength (≥ MPa) | / | |

| Grade | GR1 | Elongation (≥ %) | / | |

| Powder Or Not | Not Powder | Resistance (μΩ.m) | / | |

| Ni (Min) | 99.6 |

Product Description

Nickel fiber felt is a versatile material made from high-quality nickel fibers, featuring wide-ranging applications and excellent performance characteristics. This felt-like material is composed of uniformly distributed and interconnected nickel fibers, forming an open porous structure. Nickel fiber felt exhibits high porosity, typically ranging from 60% to 90%, allowing for efficient gas and liquid transport. Its thickness can vary based on application requirements, typically ranging from 0.25 millimeters to 1 millimeters. Additionally, nickel fiber felt has a low density, typically between 0.1 grams per cubic centimeter to 0.3 grams per cubic centimeter, making it lightweight and flexible. Furthermore, nickel fiber felt demonstrates excellent temperature resistance, withstanding high operating temperatures of up to 600 degrees Celsius, and exhibits good chemical stability, making it resistant to corrosion in harsh environments.

Nickel fiber felt finds widespread applications across multiple industries. In the field of fuel cells, nickel fiber felt is used as a Gas Diffusion Layer (GDL) to enhance the performance and durability of Proton Exchange Membrane Fuel Cells (PEMFCs) and Solid Oxide Fuel Cells (SOFCs). It promotes efficient reactant distribution, enhances water management, and improves overall cell performance. Additionally, nickel fiber felt is extensively applied in redox flow batteries, electrolyzers, supercapacitors, and water treatment systems. In these applications, it serves as a GDL, optimizing electrochemical reactions, improving battery cycling performance, and providing excellent chemical stability and high surface area.

Parameters

Material: Pure nickel fiber

Color: Light grey

Size: Customized upon request

Thickness: 0.2mm-2mm (Usually 0.25, 0.4, 0.6, 0.8, 1.0mm)

Porosity: 60-90% (It can be customized upon request)

Shape: customized (polygon, round, ring, disc, etc.)

Features

High Porosity: Nickel fiber felt has a high porosity, typically ranging from 60% to 90%. This allows for efficient transport of gases and liquids, facilitating effective mass transfer and reactions.

Uniform Wire Diameter: By utilizing the cluster drawing technique, nickel fiber felt achieves a uniform wire diameter. This uniformity ensures consistency and stability, contributing to improved performance of the material.

Lightweight and Flexibility: Due to its low density and fibrous structure, nickel fiber felt is lightweight and flexible. This characteristic enables easy handling, shaping, and installation, enhancing its versatility in various applications.

Excellent Temperature Resistance: Nickel fiber felt exhibits outstanding temperature resistance, capable of withstanding high operating conditions. It maintains stability even at temperatures up to 600 degrees Celsius, making it suitable for high-temperature processes and demanding applications.

Applications:

Fuel Cells: Nickel fiber felt is extensively used as a GDL in proton exchange membrane fuel cells (PEMFCs) and solid oxide fuel cells (SOFCs). It facilitates efficient reactant distribution, enhances water management, and improves overall cell performance.

Redox Flow Batteries: Nickel fiber felt is employed as a GDL in redox flow batteries, enabling efficient electrolyte flow and maintaining consistent electrode performance.

Electrolyzers: It is utilized as a GDL in electrolyzers to enhance the electrochemical reactions during hydrogen production.

Supercapacitors: Nickel fiber felt finds applications as a current collector and GDL in supercapacitors, enabling high power density and rapid charge/discharge cycles.

Water Treatment: It is used in electrochemical water treatment systems, such as electrocoagulation and electrochemical oxidation, due to its excellent chemical stability and high surface area.

Manufacturing flow

Nickel wire→Cluster drawing→Nickel fiber→Fiber shear→Air-laid→Sintering→Nickel fiber felt

In the overall process, cluster drawing is a crucial step in the preparation of nickel fiber. Compared to other methods like melt spinning, mechanical cutting, and monofilament drawing, the cluster drawing technique offers several advantages, including uniform wire diameter, ease of continuous production, and cost-effectiveness. This method has successfully addressed various technical challenges associated with the cluster drawing process, enabling the production of nickel fibers with different wire diameters ranging from 6 μm to 40 μm. This flexibility allows for the production of nickel fiber felts with diverse properties, catering to specific requirements.

To achieve uniform fiber lengths, a specialized cutting machine is employed to shear the fibers into desired specifications, such as 33 mm in length. This cutting process ensures consistent shearing lengths and high production efficiency. The nickel fibers are then arranged into a net using the air flow method, utilizing an imported felt laying unit. By carefully adjusting numerous complex process parameters, the resulting nickel fiber net exhibits excellent uniformity without any flaws such as bundled fibers or fiber agglomeration. Moreover, the weight of each individual fiber net can be precisely controlled as per the specific needs.

What advantages does nickel fiber felt offer over other GDL materials?

Nickel fiber felt provides high porosity, good gas diffusion properties, and excellent temperature resistance. It also exhibits chemical stability and high mechanical flexibility, making it suitable for various demanding applications.

How can nickel fiber felt improve the performance of fuel cells?

Nickel fiber felt promotes uniform gas distribution, reduces reactant crossover, and enhances water management within the fuel cell. This leads to improved performance, higher efficiency, and prolonged cell lifespan.

Is nickel fiber felt compatible with corrosive electrolytes?

Yes, nickel fiber felt demonstrates good chemical stability and is resistant to corrosion from acidic or alkaline electrolytes, making it suitable for use in various electrochemical systems.

Contact Us

- Baoji Yinggao Metal Materials Co., Ltd.

Product Categories

| sintered porous titanium filter elements | stainless steel filter | filter elements | raw material |

| other titanium | metal product | nickel | sinter titanium |

| sinter stainless steel |

New Products

-

Versatile Monel Alloy Filter Plates Precision Filtration Needs

-

0.5microns sintered porous Ti plate for PEM electrode

-

Platinum Coated Porous Titanium Sheets Electrodes For PEM Water Electrolyzer

-

5um Porous Inconel 600 Metal Filter Element

-

Titanium micro porous flow channel plates

-

4-layers Sintered Titanium Wire Mesh Filter Plate

-

Titanium electrodes with flow channels

-

Titanium Pipe for Exhaust and Downpipe

-

316L Tri Clamp Sanitary Filter for Milk Filtration

-

A 10 micron ultra-long microporous metal titanium plate

-

Titanium Plate With Flow Field For Electrolyzers

-

75um SS 304 Porous Wire Mesh Filter Cartridge

-

Porous Ti elements for temperature and humidity sensor protection cover

-

Porous Sintered Powder SS 316L Metal Plate Filter Semicircle

-

Custom interface stainless steel wire mesh filter cartridge

-

Porous Titanium Sheet for Gas Diffusion Layer

-

30um Porous Metallic Filter Cartridge With DOE

-

Ultra-fine SUS316L powder sintered filter tube

-

Sintered titanium powder filter cartridges rod filter

-

Titanium Bipolar Plate for Battery Fuel Cells

-

The 20'' standard titanium porous filter tube for filtration

-

Sintered Titanium Powder Porous Tube Filters for Liquid Filtration

-

65um M30 Connection Flat Bottom Porous Metallic Filter Element

-

M20 Connector Titanium Powder Sintered Filter Cartridge

Popular Searches

- plaster

- Filter Element

- Sintered Stone

- Diamond Saw Blade

- rare earth

- neodymium

- placing boom

- permanent magnet

- ndfeb

- neodymium magnet

- ndfeb magnet

- magnetic material

- n35

- magnetic component

- Stone Dining Table

- sintered ndfeb magnet

- sintered magnet

- sintered neodymium magnet

- wbp

- bonded ndfeb

- pcd drill bits

- pcd bits

- Metal Titanium Fiber Sintered

- stainless steel

- Nickel Alloy

- Nickel Strip

- Nickel Plate

- neodymium magnet

- nickel wire

- nickel sheet

Recommended Products

- Hastelloy G30 steel bar N06030 plate Hastelloy C-4 Bar round steel Price Nickel Alloy

- Hastelloy C-4 Steel Plate/Sheet Hastelloy steel plate ring Hastelloy Supplier with Good Price

- High Temperature Incoloy 800/800h/800ht Alloy 625 600 718 Plate Sheet Nickel Alloy Inconel Prices

- High-Temperature Resistant Alloy Stainless Nickel Steel Plate

- Nickel Base Alloy/Inconel 316 Price Inconel Price Per kg

- Alloy K500 Nickel Alloys Corrosion Resistant Alloy Stainless Steel Plate

- High Porosity 80% 70% 75% 60% 0.5mm thickness Ni sintered fiber Nickel Felts

- 250 300 400 500 600 800 Micron AEM ALK Electrolysis Ni200 Ni201 Sintered Nickel fiber felts

- nickel flange

- nickel wire

- nickel tube

- nickel rod

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Non-ferrous Metal & Products > Nickel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile