Home > Products > Nickel products > 40 Micron Stainless Steel Sintered Wire Mesh Filter Element

40 Micron Stainless Steel Sintered Wire Mesh Filter Element

- 30000000 Piece / Pieces per Month

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

-

30um titanium sintered porous metal filter tube

-

Pleated Stainless Steel Filter Oil Filter Filtration

-

Sintered Copper Brass Vent Plug Porous Metal

-

5Um Micron 316L Stainless Steel Sparger porous stainless steel filter element filtration air diffuser powder metallurgy

-

Micron 316L Stainless Steel filter cartridges porous stainless steel filter element filtration sintered metal filter disks filter discs

-

5um Porous Parts Sintered Copper Filter Disc porous bronze filter porous bronze sheet sintered bronze filter brass filter

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | SSM-07 | Application | filtration,ozone diffusion filter,water treatment | |

| Technique | Sintered | Grade | Nickel wire mesh | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

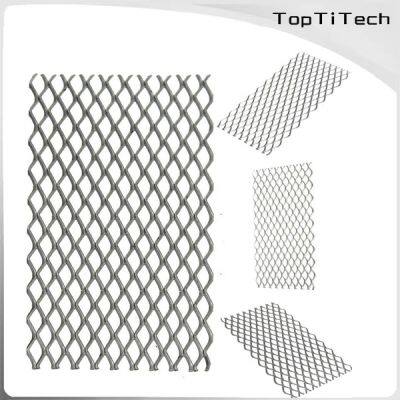

40 Micron Stainless Steel Sintered Wire Mesh Filter Element is a type of filter that is made by sintering multiple layers of stainless steel wire mesh together. Sintering is a process that involves compacting and heating a material without melting it, which causes the particles to fuse together and form a solid mass.

40 Micron Stainless Steel Sintered Wire Mesh Filter Element consists of multiple layers of wire mesh that are stacked and then sintered together. The sintering process creates a solid bond between the wires, resulting in a robust and durable filter element that can withstand high temperatures, pressures, and corrosive environments.

Parameter

Material: stainless steel

Grade:SS 316L, SS 304L, SS 316, SS 304

OD: Max. 200mm

Length: Max. 1500mm

Accuracy / Pore Size: 0.2um-200um

Porosity: 30%-60%

Temperature resistance: ≤300℃

Technique: Sintering Process

Surface: Smooth, clean and metallic

The function of each layer in the five-layer stainless steel wire mesh sintered filter element:

A five-layer stainless steel wire mesh sintered filter element is composed of multiple layers of wire mesh that are stacked and bonded together using a sintering process. Each layer of the filter element serves a specific function in the filtration process. The following is a breakdown of the function of each layer:

Outer Protective Layer: The outermost layer of the filter element is usually a coarse mesh that serves as a pre-filter to capture larger particles and prevent them from clogging the finer inner layers. This layer also protects the finer inner layers from damage.

Intermediate Protective Layer: The second layer is also a coarse mesh that provides additional protection to the finer inner layers. This layer helps to prevent the filter element from being damaged by high-pressure or high-velocity fluid flows.

Inner Filter Layer: The third layer is composed of a finer mesh size and serves as the primary filter layer. This layer is responsible for capturing smaller particles that were not captured by the outer protective layers.

Reinforcing Layer: The fourth layer is a coarser mesh size than the inner filter layer and serves as a reinforcing layer. It provides mechanical support to the inner filter layer and helps to prevent it from collapsing under high-pressure or high-velocity fluid flows.

Inner Protective Layer: The fifth and final layer is the finest mesh size layer that provides additional protection to the inner filter layer. This layer captures the smallest particles and prevents them from passing through the filter element.

Overall, the five-layer stainless steel wire mesh sintered filter element provides efficient and effective filtration by using layers of different mesh sizes to capture particles of various sizes. The protective layers also help to prevent damage to the finer inner layers and ensure the longevity of the filter element.

Feature

40 Micron Stainless Steel Sintered Wire Mesh Filter Element has several advantages over other types of filters.

First, it has a uniform and controlled pore size, which ensures consistent filtration performance. Second, it has a high dirt-holding capacity, which means that it can capture a large amount of contaminants before needing to be cleaned or replaced.

Third, it has excellent mechanical strength, allowing it to withstand high pressures and mechanical stresses.

Fourthly, it can be cleaned and reused, making them a cost-effective and environmentally friendly filtration solution.

Application

1. Chemical Processing: Stainless steel wire mesh sintered filter elements are commonly used in the chemical processing industry to filter aggressive chemicals, acids, and alkalis. They can withstand harsh chemical environments and high temperatures, making them ideal for chemical filtration.

2. Oil and Gas Industry: The oil and gas industry uses stainless steel wire mesh sintered filter elements to remove impurities and contaminants from oil, gas, and other fluids. They are used in drilling, production, and refining processes, where high temperatures, pressures, and corrosive environments are common.

3. Food and Beverage Processing: Stainless steel wire mesh sintered filter elements are widely used in food and beverage processing to remove impurities and contaminants from liquids, such as beer, wine, and juice. They are also used to purify water and other ingredients in the production process.

4. Pharmaceuticals: Stainless steel wire mesh sintered filter elements are used in the pharmaceutical industry to filter and purify medications, vaccines, and other pharmaceutical products. They are also used in cleanrooms and other critical environments that require high levels of filtration.

5. Water Treatment: Stainless steel wire mesh sintered filter elements are used in water treatment to remove impurities and contaminants from water, such as sediment, bacteria, and viruses. They are used in municipal water treatment plants, industrial wastewater treatment, and residential water filtration systems.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

Titanium Powder Diffuser Aerator Ozone Hydrogen Oxygen Pure Titanium Aerator Head For Sewage Treatment Ozone Aeration

-

Nickel Mesh Anode in AEM electrolyser for Hydrogen Production Nickel anode nickel cathode AEM Water Electrolyzer

-

Sintered 5 Layers Stainless Steel Wire Mesh Filter Sintered Stainless steel mesh filter cartridges oil filter filtration

-

1mm Thickness Titanium Sintered Metal Porous Filter Plate porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

20 inch metal?sintered?powder?filter?cartridge porous metal filter filtration Powder Metallurgy water treatment PEM Electrolysers

-

1um Porous Titanium Candle Filter Pipe Cartridge porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

Customized 30 microns porous titanium curved microplate for filtration porous titanium filter plates PEM Electrolyzers

-

wave stainless steel wire mesh filter cartridges cleanable

-

M20 thread interface metal filter tube 20 inch metal?sintered?powder?filter?cartridge porous metal filter filtration Powder Metallurgy water treatment

-

70% Porosity Titanium Fiber Paper Felt for GDL Customized titanium fiber felt 0.2mm 0.4mm for Fuel cell electrolyzers filtration

-

Sintered Stainless Steel Sparger For Bioreactor Systems Diffusion Stone porous stainless steel filter air diffusion stone fine bubbles

-

Titanium Powder Corrugated Plate for Heat Exchanger porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

20um 316L microporous stainless steel filter disc air Diffusion Stone porous stainless steel filter fine bubbles

-

Stainless Steel Hydrogen Dissolving Rod Diffusion Stone porous stainless steel filter fine bubbles stone hydrogen-rich water

-

50 microns Multiple Layers Mesh Cylinder Filter Element Wire Mesh Filter Element Sintered 5 Layers Stainless Steel wire mesh filters

-

Sintered porous candle filter with M30 interface porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

Porous Stainless Steel Filter Tubes Water Filter air Diffusion Stone porous stainless steel filter cup

-

30" Titanium Porous Filter Element With M36 Interface porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

316L Five-layers sintered mesh filter disc Wire Mesh Filter Element Sintered 5 Layers Stainless Steel wire mesh filters

-

Titanium sponge

-

Titanium foil

-

1um 1 micron porous metal instrument filters with flange interface porous titanium filter Powder Metallurgy filtration porous filter

-

Titanium scrap Gr5 Titanium scrap turnings for Ferro Titanium

-

OD 30mm Titanium Porous Filter Element With M20 sintered titanium filter

Popular Searches

- Filter Element

- fuel filter

- Woven Wire Mesh

- Oil Filter Element

- Hydraulic Oil Filter

- galvanized wire mesh

- hydraulic filter

- air filter element

- Hydraulic Filter Element

- Screen Pipe

- Cartridge Filter Element

- Filter Disc

- Glass Fiber Filter

- stainless steel filter disc

- wedge wire filter element

- Epoxy Coated Wire Mesh

- Cylinder Filter Element

- hydraulic filter replacement

- vickers filter

- lube oil filter element

- hydraulic filter cross reference

- hydraulic suction filter

- internormen filter element

- wire mesh filter cartridge

- wire mesh hydraulic filter

- wire mesh oil filter

- stainless steel

- wire netting

- chain link fence

- wire mesh fence

Recommended Products

- Shengrui Barrier Explosion proof Material Pry Loading Tank Oil Depot Barrier Explosion proof Material Filling Material Maintenance Easy

- Explosion proof oil tank barrier, explosion-proof filling, explosion-proof flame retardant, pry mounted tank, gas station customization, Shengrui

- Production and supply of horizontal carbon steel oil tanks, insulated iron sheet tanks, second-hand carbon steel storage tanks

- Methanol tank multifunctional metal tank, iron tank, fire tank, oil storage tank

- Double layer tank SF tank FF gas station construction one-stop composite pipeline submersible pump

- SF double-layer oil storage tank, large capacity horizontal storage tank, suitable for a wide range of applications, good sealing performance,

- Undertaking the construction of gas station canopy and grid structure, interior and exterior decoration, buried oil tank composite pipeline, Shengrui

- SF double-layer tank buried gas station with a thickness of 2.5mm for a 20 cubic meter double-layer oil tank

- Explosion proof oil tank barrier, explosion-proof filling, explosion-proof flame retardant, pry mounted tank, gas station customization, Shengrui

- 10 microns Nickel Powder Wire Mesh Composite Porous Plate

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- High Quality Large central state-owned enterprises Storage Tank tower reactor

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Karry

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Karry

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile