Home > Products > stainless steel filter > Multi-layer sintered metal mesh filter self backwashing 50um

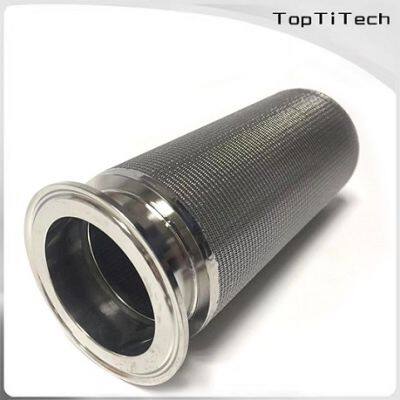

Multi-layer sintered metal mesh filter self backwashing 50um

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | SSF-22 | Application | filtration,ozone diffusion filter,water treatment | |

| Technique | Sintered | Grade | 304, 316L | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

Multi-layer sintered metal mesh filters combine the advantages of woven wire mesh, with micron-level pore sizes and a diffusion-bonded wire mesh laminated plate, to provide mechanical strength and stability. Typically, fine woven metal wire mesh filters are placed within multiple layers of sintered laminated plates to protect the fine mesh from mechanical damage caused by environmental pressure. 5-layer sintered laminated plates are commonly used for sintered wire mesh filters.

Due to their stability, mechanical strength, and durability, multi-layer sintered metal mesh filters can be made into various sintered filter elements, such as cylinders, filter cartridges, candles, and discs. TOPTITECH provides customized sintered wire mesh filters to meet your specific requirements. We are committed to providing customers with high-quality filtration solutions, ensuring stability and efficiency in various applications.

Parameters

Material: SUS334L SUS316L

layers: single layer, 2 to 3 layers, 5 layers, and 6 layers or customized

Sheet size:18" × 48" 24" × 48" customized

Features

1. Uniform pore size: has a uniform pore size distribution, which can ensure that the material can pass through the filter element evenly during the filtration process, thereby achieving more efficient filtration. In addition, the uniform pore size distribution reduces clogging and damage to the filter element, thereby extending its service life.

2. High-temperature resistance and corrosion resistance: The stainless steel wire mesh filter element is made of high-quality stainless steel, which has excellent high temperature resistance and corrosion resistance. Even in an environment of high temperature or corrosive media, the filter element can maintain its structural integrity and filtration performance, thus ensuring the stability and durability of the filtration effect.

3. Cleanable and Reusable: The stainless steel wire mesh filter element can maintain its filtering performance with simple cleaning and maintenance, making it reusable. The reusability of stainless steel wire mesh filters reduces environmental impact and is more economical than disposable filters.

4. Micron-level pore size: The micron-level pore size of the stainless steel wire mesh filter element can effectively filter out tiny particles and impurities, thereby improving the filtering effect and filtering accuracy. Micron-sized pores can also help protect downstream equipment, such as pumps and valves, from damage and failure caused by the intrusion of fine impurities.

Different layers have different performance characteristics

Single layer sintered wire mesh is formed by diffusion bonding, resulting in a permanent geometric shape, pore size, and filtration level. It is a cost-effective alternative to mesh filters and is commonly found in discs, rings, and simple cylindrical shapes.

Two to three layers of sintered wire mesh have good mechanical strength and medium-sized pores, suitable for manufacturing pleated cylindrical filters, candle filters, and sintered discs. This type of sintered wire mesh has a filtering layer with the desired pore size sandwiched between outer and inner protection layers.

Five-layer sintered wire mesh consists of one layer of fine woven wire mesh sandwiched between two layers of coarser woven wire mesh protection layers. These three layers of woven wire mesh are then sintered together with two support layers to enhance the filtration performance. This type of sintered metal wire mesh laminated plate has a wide range of applications in chemical processing, food, and beverage, pharmaceuticals, and transportation, and is used for liquid and gas filtration, fluidized beds, and other applications.

Application

Oil and gas production

Drug

Chemical industry

Food

Aerospace

Polymer filtration

Energy and Nuclear Power

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

Sintered Copper Brass Vent Plug Porous Metal

-

5Um Micron 316L Stainless Steel Sparger porous stainless steel filter element filtration air diffuser powder metallurgy

-

Micron 316L Stainless Steel filter cartridges porous stainless steel filter element filtration sintered metal filter disks filter discs

-

5um Porous Parts Sintered Copper Filter Disc porous bronze filter porous bronze sheet sintered bronze filter brass filter

-

Titanium Powder Diffuser Aerator Ozone Hydrogen Oxygen Pure Titanium Aerator Head For Sewage Treatment Ozone Aeration

-

Nickel Mesh Anode in AEM electrolyser for Hydrogen Production Nickel anode nickel cathode AEM Water Electrolyzer

-

Sintered 5 Layers Stainless Steel Wire Mesh Filter Sintered Stainless steel mesh filter cartridges oil filter filtration

-

1mm Thickness Titanium Sintered Metal Porous Filter Plate porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

20 inch metal?sintered?powder?filter?cartridge porous metal filter filtration Powder Metallurgy water treatment PEM Electrolysers

-

1um Porous Titanium Candle Filter Pipe Cartridge porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

Customized 30 microns porous titanium curved microplate for filtration porous titanium filter plates PEM Electrolyzers

-

wave stainless steel wire mesh filter cartridges cleanable

-

M20 thread interface metal filter tube 20 inch metal?sintered?powder?filter?cartridge porous metal filter filtration Powder Metallurgy water treatment

-

70% Porosity Titanium Fiber Paper Felt for GDL Customized titanium fiber felt 0.2mm 0.4mm for Fuel cell electrolyzers filtration

-

Sintered Stainless Steel Sparger For Bioreactor Systems Diffusion Stone porous stainless steel filter air diffusion stone fine bubbles

-

Titanium Powder Corrugated Plate for Heat Exchanger porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

20um 316L microporous stainless steel filter disc air Diffusion Stone porous stainless steel filter fine bubbles

-

Stainless Steel Hydrogen Dissolving Rod Diffusion Stone porous stainless steel filter fine bubbles stone hydrogen-rich water

-

50 microns Multiple Layers Mesh Cylinder Filter Element Wire Mesh Filter Element Sintered 5 Layers Stainless Steel wire mesh filters

-

Sintered porous candle filter with M30 interface porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

Porous Stainless Steel Filter Tubes Water Filter air Diffusion Stone porous stainless steel filter cup

-

30" Titanium Porous Filter Element With M36 Interface porous titanium filter Powder Metallurgy filtration PEM electrolysers

-

316L Five-layers sintered mesh filter disc Wire Mesh Filter Element Sintered 5 Layers Stainless Steel wire mesh filters

-

Titanium sponge

Popular Searches

- water treatment

- water filter

- filter cartridge

- auto parts

- air filter

- oil filter

- Filter Element

- wire mesh

- fuel filter

- cartridge filter

- filter screen

- Ceramic Foam Filter

- wire mesh filter

- filter mesh

- oil regeneration

- hydraulic filter

- Coffee Filter

- Panel Air Filter

- Grease Filter

- Filter Plate

- Metal Mesh Filter

- Metal Mesh Pre Filter

- ceramic honeycomb filter

- Pe Filter Bag

- filter cartridge

- Air Purifier

- air cleaner

- Filter Cloth

- Liquid Filter Bag

- Stainless Steel Wire Mesh

Recommended Products

- Manufacturers sell welding grade rutile sand

- 95% Rutile sand for welding electrodes

- 95% rutile sand, specifically used for welding electrodes.

- 95% rutile sand, specifically used for welding electrodes.

- 95% Rutile sand for welding electrodes

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- High purity 95% rutile sand

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- Petrochemical oil storage tank barrier explosion-proof material for gas stations, with a wide range of applications

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile