Home > Products > titanium filter > Titanium Sintered corrugated plate

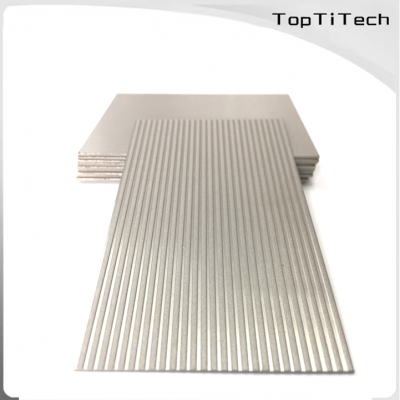

Titanium Sintered corrugated plate

- 30000000 Piece / Pieces per Month

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

-

Powder Sintered Filter Elements For Filtration

-

Sus316L Powder Sintered Filter Cartridge

-

Sintered metal filter screen

-

Porous metal explosion-proof filter element

-

Deep pleated filter cartridges for air oil filtration

-

Titanium Powder Diffuser Aerator for Ozone Hydrogen Oxygen Diffusion Oxygenating Water 100MM,150MM

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | TF-01 | Application | filtration,ozone diffusion filter,water treatment | |

| Technique | Sintered | Grade | pure Titanium | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

The sintered corrugated plate is a corrugated plate made by the powder metallurgy process. It is usually made of metal or alloy powder through mixing, pressing, sintering, and other processes, and has excellent properties such as high strength, corrosion resistance, and high-temperature resistance.

The manufacturing process of powder-sintered corrugated board is relatively simple, and can be customized according to specific needs, with high material utilization and production efficiency. At the same time, its corrugated shape can increase its surface area and channel length, improving its filtration and separation efficiency. In the fields of chemical industry and petroleum, the powder-sintered corrugated plate has become a kind of necessary filtration and separation equipment.

In applying titanium sintered corrugated plate and ordinary titanium sintered plate in the electrolytic cell, titanium sintered corrugated plate has some advantages over ordinary titanium sintered plate.

First, the corrugated shape of the titanium sintered corrugated plate can increase its surface area and channel length, which helps to improve the efficiency and yield of the electrolysis reaction.

Secondly, the titanium sintered corrugated plate can improve the fluidity and mixing of the electrolytic cell, which is beneficial to the electrolyte′s uniform distribution and the reaction product′s rapid discharge.

The corrugated structure on the surface of the titanium sintered corrugated plate can indeed increase the electrode surface area, increase the current transfer efficiency, and thus improve the electrolysis efficiency. In addition, it can also increase the mechanical strength and stability of the electrode, reduce the electrode′s deformation and damage, prolong the electrode′s service life, and reduce the maintenance cost. Therefore, the corrugated structure on the surface of titanium sintered corrugated plate has important application value in electrochemistry, but it does not directly affect the conductivity in the electrolyte solution.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

Sintered Stainless Steel Porous Metal Filter Tube Filter cup

-

Sintered Porous Titanium Rod Filter Element For Filtration

-

Sintered Porous Titanium Powder Filter Cartridges for Filtration

-

Muti-layer Stainless Steel Sintered Mesh Filter Element

-

10um sintered porous Ti Titanium plate for gas diffusion

-

Sintered Titanium Frit for PEM Electrolyzers

-

Pure Titanium Electrode Porous Fiber Felts For PEM Fuel Cell

-

Stainless steel sintered mufflers

-

Polished stainless steel powder filter elements

-

Nickel Foam Plate For Sound Absorbing Instrument

-

Parallel Filter Element for oil purification

-

Sintered Nickel Fiber Felt For PEM Electrolyzer GDL

-

Sintered Porous Powder Metal SS 316L Cap Filter

-

Porous titanium round plate Diffusion Layer Hydrogen Electrode

-

Sintered 5 Microns Porous Stainless Steel Filter tube

-

0.8um Microns Titanium Sintered Porous Metal Filter Cartridge

-

Porous?0.5 micron SS316L?stainless?steel?filter?discs filter disks

-

Porous Stainless Steel Flame Arrestors

-

20um Micron Parallel Oil Filter Element Stainless Steel

-

40 Microns Stainless Steel Wire Mesh Filter Pipe

-

20'' porous titanium rod filter water treatment filter

-

Ti-Based Gas Diffusion Layer anode titanium GDL

-

20 Microns Anode PTL/GDL Porous Titanium Frit

-

Platinized Titanium Fiber Felt For PEM Electrolyzer GDL

Popular Searches

- water treatment

- water filter

- filter cartridge

- auto parts

- air filter

- oil filter

- Filter Element

- wire mesh

- fuel filter

- cartridge filter

- filter screen

- Ceramic Foam Filter

- wire mesh filter

- filter mesh

- oil regeneration

- hydraulic filter

- Coffee Filter

- Panel Air Filter

- Grease Filter

- Filter Plate

- Metal Mesh Filter

- Metal Mesh Pre Filter

- ceramic honeycomb filter

- Pe Filter Bag

- filter cartridge

- ceramic ball

- Filter Element

- slurry

- shock absorber

- titanium plate

Recommended Products

- 95% Rutile sand for welding electrodes

- High purity 95% rutile sand

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- 95% rutile sand, specifically used for welding electrodes.

- 95% Rutile sand for welding electrodes

- Petrochemical oil storage tank barrier explosion-proof material for gas stations, with a wide range of applications

- Easy to maintain, fire-resistant honeycomb oil tank material has good anti-aging performance,

- Special explosion-proof barrier materials for gas stations are easy to maintain and widely used in various fields

- Gas station double-layer composite pipeline, buried oil pipeline, thermoplastic wear-resistant composite pipe, Shengrui

- Shengrui Barrier Explosion proof Material Pry Loading Tank Oil Depot Barrier Explosion proof Material Filling Material Maintenance Easy

- Explosion proof oil tank barrier, explosion-proof filling, explosion-proof flame retardant, pry mounted tank, gas station customization, Shengrui

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel