Home > Products > testing equipment > TD521S-30/60/100 Double horizontal shaft concrete Mixer

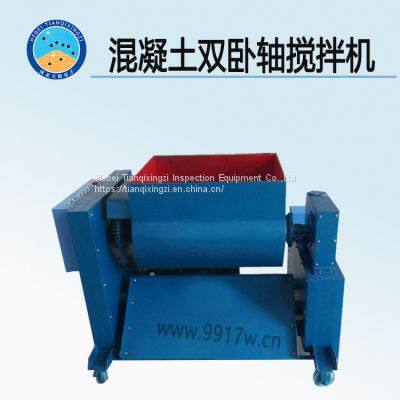

TD521S-30/60/100 Double horizontal shaft concrete Mixer

- tianjin

- 7 days

You May Like

-

TDBJC electric steel bar gauge bar marking meter

-

TDBJ manual steel bar gauge

-

TD558 - J Cement concrete bending tensile resistance Set of test

-

TD558 - J Cement concrete bending tensile resistance Set of test

-

TD560 - J The concrete cube splits Test fixture

-

TDNA - type 1 Mud sand content Measuring instrument

Product Details

| Brand Name | tianqi | Place of Origin | China | |

| Model Number | TD521S-30/60/100 |

Product Description

Lightweight concrete and dry hard concrete can also be used in other industry laboratories for mixing different materials. The double horizontal shaft concrete mixer implements the standard JG24420092.

The product structure modeling of double horizontal shaft concrete mixer has been included in the mandatory national industry standard "Concrete Test Mixer" (JG244-2009), and the product performance meets the standard

Exceeding standard requirements. Due to the scientific and reasonable design, strict quality control and its unique structure, the double horizontal shaft concrete mixer has high mixing efficiency,

The mixture is more uniform, discharge cleaner and so on. Concrete double horizontal shaft mixer is ideal because of its convenient operation, high mixing efficiency, small residual amount and convenient cleaning

Laboratory concrete mixing equipment.

Ii. TD521S-60 Concrete Double horizontal Shaft Mixer Technical parameters:

1. Maximum discharge capacity: 60 liters;

2, mixing time: ≤30 seconds;

3, mixer speed: 47 RPM;

4, motor power: 4 kW;

5, power supply voltage: 380 volts;

6, product net weight: 700 kg;

7. Overall size: 1100×900×1050;

8. Mixing cylinder material: 16Mn steel;

9. Mixing leaf material: 16Mn steel;

10. Clearance between blade and cylinder wall: 1mm;

11, cylinder wall thickness: 100mm blade thickness: 12mm.

Three, the working principle of the structure

Concrete double horizontal shaft mixer is composed of frame, mixing device, transmission system, limit device and electrical control system. The frame is the supporting part of the whole equipment, which is welded by channel steel. The stirring device is composed of a stirring cylinder, a stirring shaft and a stirring spatula. The stirring spatula is fixed on the stirring arm and is integrated with the stirring shaft to form two groups of spiral belt stirring spatula with opposite directions but the same lead and spiral Angle. The transmission mechanism is composed of decelerating civil aircraft and coupling, the cylinder limit device is composed of locking pin and positioning hole, and the electrical control system has the functions of starting, starting, stopping and timing. Working principle: The reducer motor makes the stirring shaft rotate in one direction through the connecting shaft, and the positive and negative sets of spatula on the stirring shaft stir materials. Due to the role of spiral Angle, the spatula works so that the material in the cylinder is pushed from one side to the other side, and then pushed back to the original place by the other side of the circular action, so that the material is fully stirred, so as to obtain the ideal stirring effect. Stop the machine when discharging the material, set the lock, make the cylinder rotate at a certain Angle, then limit the position, press the button to discharge the mixture out of the cylinder.

Double horizontal shaft concrete mixer mounted

After the machine is unpacked, check whether the deceleration motor, barrel and bearing seat are damaged during transportation, and whether the fasteners are loose. If they are loose, they should be tightened. The supporting foundation is a flat concrete ground.

Double horizontal shaft concrete mixer operating procedures

1. Before starting, check whether the rotating part and the cylinder scratch or not. If there is any scratch, it should be adjusted in time.

2. Clean the sundries in the barrel.

3. The cylinder should be limited before starting

4. The rotation direction of the stirring shaft shall be as indicated on the end face of the cylinder.

5, into the concrete material must be removed metal or other debris.

6. Adjust the timing of the agitator according to the stirring time. Note that it must be adjusted under the condition of short electricity.

Contact Us

- Hebei Tianqixingzi Inspection Equipment Co.,Ltd

Product Categories

| products | testing equipment |

New Products

-

TD502-2 environment-friendly negative pressure sieve analyzer

-

TD3810-2 series Ceramic tile flatness, straight Angle, Integrated edge straightness tester

-

TD3810-6 Series wear-resisting Depth Tester for unglazed Ceramic Bricks (also known as inorganic material wear-resisting tester)

-

TD6670-2 sponge foam falling ball rebound tester

-

TD3810-5A Impact Resistance Tester for ceramic bricks (also known as recovery coefficient tester)

-

TD3810-8 linear thermal expansion tester for ceramic bricks

-

Low temperature flume (also known as thermal shock resistance tester for Ceramic bricks)

-

TDH-TH70 standard concrete carbonation test chamber

-

TD720-2 asphalt mixture line shrinkage coefficient tester

-

TD528 series concrete mix bleeding rate tester

-

TD605-4 asphalt liquid significant low temperature elongation tester

-

TDJC-H series waterproof coil thickness tester

-

TDSJ-KS2 Cement mortar impermeability Tester (mortar permeability tester)

-

TD624 series asphalt viscosivity tester

-

TDJG3050-16 type electric casing digital display constant temperature water bath

-

TD130-1 variable head penetration tester

-

Porous ceramic apparent porosity bulk density tester

-

Emulsified asphalt and cement mixing tester (also known as: emulsified asphalt demulsification speed tester)

Popular Searches

- mixing machine

- concrete mixer

- cement mixer

- concrete vibrator

- concrete mixing plant

- concrete batching plant

- Portable Concrete Mixer

- Concrete Mixing Machine

- mortar mixer

- mini mixer

- Hydraulic Concrete Mixer

- grout mixer

- volumetric concrete mixer

- large concrete mixer

- twin-shaft concrete mixer

- lab equipment

- analysis instrument

- testing equipment

- test equipment

- Test Chamber

- testing instrument

- Measuring Machine

- Test Machine

- Hardness Tester

- material testing

- test bench

- Tensile Tester

- Universal Testing Machine

- Tensile Testing Machine

- material testing machine

Recommended Products

- ABB XE08B5-d04 1SBP260106R1001

- ABB 07KR51-O22 1SBP260011R1001

- ABB TU515 /1SAP212200R0001

- ABB 57310001-MP/DSPC172H

- ABB 6240BP10412 6240BP10422 6240BP10432

- ABB 6245BP10710 6245BP10720 6245BP10730

- ABB 6246BP10811 6246BP10821 6246BP10830

- ABB 6230BP10710 6230BP10720 6230BP10730

- ABB 6247BP10730

- ABB 6247BP10720

- ABB 6247BP10710

- AC LV Withdrawable Switchgear

Find Similar Products By Category

- Electrical & Electronics > Power Transmission & Transformer > Transformer

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile