Home > Products > Cooling Tower Filler > High Performing Splash ML PVC Cooling Tower Fills MX75 Cooling Tower fill Media Crossflow Infill Marley film fills

High Performing Splash ML PVC Cooling Tower Fills MX75 Cooling Tower fill Media Crossflow Infill Marley film fills

Negotiable

1 (Min. Order)

- T/T Credit Card

You May Like

-

CF1900/CF1200 Cross Fluted Film Fill Media For Cooling tower Replacement Fill Patterns in fill

-

Cooling Tower PP PVC Infill Packing Media 750mm*800mm 1000mm*1200mm Counter Flow Cooling Tower Filling Sheet Material

-

PP PVC 1330mm 1300mm 380mm Industrial Cooling Tower Fill Media with Drift Eliminator

-

virgin PVC 500mm S wave counter flow cooling tower fill pack

-

Best selling cooling tower PVC PP fill 1000mm*1200mm 750mm*800mm 750mm*1600mm cross flow cooling tower fill media

-

High Quality 730mm*730mm 730mm*1000mm PP PVC Cross-Flow Cooling Tower Filler Material

Product Description

Product Description

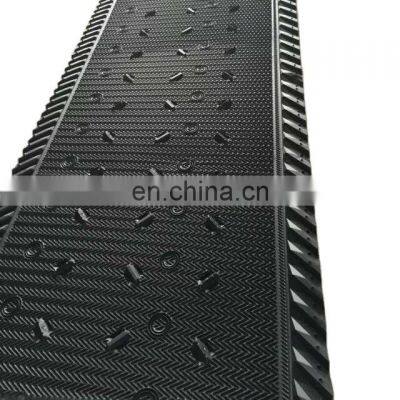

High Performing Splash ML PVC Cooling Tower Fills MX75 Cooling Tower fill Media Crossflow Infill Marley film fills

Cooling Tower Fill Principles of Operation

The application of pp film fill is to cooling hot waste. The fill is sheet type, so water flowing have much more surface area. hot water will be cooled quickly. This is the reason people use film fill proverbially. The principles of operation is:

Cooling tower fill makes hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly. After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water,and the warm air leaving the fill and releasing from the above of the cooling towers, and like this Continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously.

The waste heat produced in industrial production or refrigeration process is generally driven away by cooling water. The cooling tower functions as heat exchange between the cooling water carrying waste heat and air in the tower.

What is the purpose of fill in a cooling tower?

The purpose of fill in a cooling tower is to cool water to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

Matters needing attention when replacing the cooling tower packing.

♦ The waveforms between the monolithic and the monolithic must be diagonally staggered so that they have good thermal resistance.

♦ The cuboidal packing assembly unit is most suitable for matching with the square tower and with the circumference of the circular cooling tower. A gap will be formed, and it needs to be filled with a different number of single sheets according to the size of the gap.

♦ Once the plug is blocked, it is not easy to clean. When the jam is serious, it needs to be replaced as a whole and it will increase the cost

The application of pp film fill is to cooling hot waste. The fill is sheet type, so water flowing have much more surface area. hot water will be cooled quickly. This is the reason people use film fill proverbially. The principles of operation is:

Cooling tower fill makes hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly. After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water,and the warm air leaving the fill and releasing from the above of the cooling towers, and like this Continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously.

The waste heat produced in industrial production or refrigeration process is generally driven away by cooling water. The cooling tower functions as heat exchange between the cooling water carrying waste heat and air in the tower.

What is the purpose of fill in a cooling tower?

The purpose of fill in a cooling tower is to cool water to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

Matters needing attention when replacing the cooling tower packing.

♦ The waveforms between the monolithic and the monolithic must be diagonally staggered so that they have good thermal resistance.

♦ The cuboidal packing assembly unit is most suitable for matching with the square tower and with the circumference of the circular cooling tower. A gap will be formed, and it needs to be filled with a different number of single sheets according to the size of the gap.

♦ Once the plug is blocked, it is not easy to clean. When the jam is serious, it needs to be replaced as a whole and it will increase the cost

Specification

Type | 1520mm Marley PVC Cooling Tower Fill Packing Marley Cooling Tower film |

Material | PVC |

Color | Black ,grey,blue ,green |

Pitch | 19mm |

Thickness | 0.3-0.6mm |

length | any |

Tensile strength | Longitudinal direction 47.0 MPA, landscape proentation:42.0 MPA |

width | 920mm 1020mm, 1220mm 1520mm |

Application tempereture | -15℃~65℃ |

Used for tower | Crossflow cooling tower |

Product details

Marley film fill is one of the most important components for exchange of gas and water in Marley cooling tower. cooling tower fill is the major part to improve cooling tower working efficiency and make sure the economy and safe operation. With the development of plastic industry, cross-current tower drench waste water into corrugated fills, which has many advantages like heat dissipation, durable, good performance, small ventilation resistance , etc. Based on these easy and other advantages it is widely used in different types of large, medium and small cooling towers.

How to choose Cooling Tower fill?

Both splash and film fill are ideal for facilitating the evaporation and cooling process in a cooling tower. However, film fill media is more efficient in heat transfer as it creates a larger surface area, hence optimized performance. However, it is more susceptible to wear and tear due to constant exposure to water at very high temperatures.

If your cooling tower applications involve recirculating water with poor quality and high solids content, you may opt for splash fill media for better performance. Also, if water is generated at very high temperatures, you may consider splash fill media with metallic bars as film fill media will wear away prematurely.

Cooling towers are essential equipment in most manufacturing industries. With this knowledge, you can choose the right type of tower fill media for optimal performance and improved efficiency of your industry's cooling tower.

The cooling tower is the main core of heat dissipation for circulating water in industrial production. In China's industrial

production, it affects the cost and efficiency of industrial production in China.

Inappropriate use of cooling towers in industrial production can result in inefficient heat dissipation, production stagnation, and high water temperature risk. Cooling tower packing is the main factor that promotes hydrothermal cycle. Therefore, we must choose high-quality cooling tower packing.

♦ First, the cross-flow cooling tower standard size.

The distance between the top of the cooling tower packing and the bottom of the fan should be 1.2 times the diameter of the fan.

♦ Second, counterflow cooling tower standard angle.

1. When constructing a counterflow cooling tower, the top of the packing and the airflow section should be controlled within 90 degrees. A flat top cover is used and a diversion coil is installed. The water eliminator and the airflow section are angled at 90-120 degrees. between.

2. Shrink-type tower top, the top corner of the shrinkage section cover should be controlled between 90-110 degrees.

3. the water filling angle is controlled between 5-8 degrees.

Both splash and film fill are ideal for facilitating the evaporation and cooling process in a cooling tower. However, film fill media is more efficient in heat transfer as it creates a larger surface area, hence optimized performance. However, it is more susceptible to wear and tear due to constant exposure to water at very high temperatures.

If your cooling tower applications involve recirculating water with poor quality and high solids content, you may opt for splash fill media for better performance. Also, if water is generated at very high temperatures, you may consider splash fill media with metallic bars as film fill media will wear away prematurely.

Cooling towers are essential equipment in most manufacturing industries. With this knowledge, you can choose the right type of tower fill media for optimal performance and improved efficiency of your industry's cooling tower.

The cooling tower is the main core of heat dissipation for circulating water in industrial production. In China's industrial

production, it affects the cost and efficiency of industrial production in China.

Inappropriate use of cooling towers in industrial production can result in inefficient heat dissipation, production stagnation, and high water temperature risk. Cooling tower packing is the main factor that promotes hydrothermal cycle. Therefore, we must choose high-quality cooling tower packing.

♦ First, the cross-flow cooling tower standard size.

The distance between the top of the cooling tower packing and the bottom of the fan should be 1.2 times the diameter of the fan.

♦ Second, counterflow cooling tower standard angle.

1. When constructing a counterflow cooling tower, the top of the packing and the airflow section should be controlled within 90 degrees. A flat top cover is used and a diversion coil is installed. The water eliminator and the airflow section are angled at 90-120 degrees. between.

2. Shrink-type tower top, the top corner of the shrinkage section cover should be controlled between 90-110 degrees.

3. the water filling angle is controlled between 5-8 degrees.

Product application

1520mm Marley PVC Cooling Tower Fill Packing Marley Cooling Tower film Cross flow cooling tower fill make the water meet th air crossly, when cooling tower air entry the tower from two sides , the hot water come into the tower from top, this meeting between hot water and cooling air was named cross flow, the result is the water become the lower temperature and flow away from the tower bottom, and the hot air is uprising in the tower top

Packing & Delivery

1220mm ML Hanging Fill Cross flow drift eliminator cooling tower fill PVC material packing

Company Profile

Related Products

Contact

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Contact Us

- Hebei Lanyu Rubber & Plastic Products Co., Ltd.

Product Categories

New Products

-

PVC new design Eac Cooling Tower Fills, Eac Cooling Tower Material Fills

-

PVC PP 400mm 800mm 1200mm 1600mm Counter Flow Cooling Tower Fill Media

-

0.3mm thickness counter flow 750mm*800mm PVC fill for cooling tower

-

200mm 250mm 300mm PP PVC Rolled Type Round Cooling Tower Fill Media

-

High Quality 730mm*730mm PP PVC Cross-Flow Cooling Tower Fill Media

-

200mm 250mm 300mm PP PVC Roll Type Round Cooling Tower Filling Media

-

China supply Marley PP PVC Cooling Tower Fill Packing media MX 75 Fill

-

MX75 1220mm*2980mm*0.38mm PP PVC ML Cross-Flow Cooling Tower Fill Media

-

35mm pitch PVC filter bio media blue PVC fill for cooling tower

-

Best Selling Cooling Tower PVC PP Fill Sheet Media 150mm 305mm 610mm Cooling Tower Fill Package

-

High Quality PP PVC CPVC Roll Type Filling 200mm 250mm 300mm Cooling Tower Fill Media

-

high quality PVC material gray color cooling tower fill pack

-

Oblique Wave Filling Media 150mm 305mm 610mm PVC PP Counter-Flow Cooling Tower Fill Block

-

CF1900 Cross Fluted Film Fill Media For Cooling Tower Cooling Tower Fill Price

-

ML Cooling Tower Filling Media 1220mm PVC PP Hanging Cross-Flow Cooling Tower Fill Packing

-

500mm width blue cooling tower fill water treatment PVC bio media

-

0.5mm 1mm thickness PP lamella clarifier plate 50mm inclined tube settler modules

-

High Quality 500mm 750mm PP PVC Material S Wave Cooling Tower Fill

-

500mm 750mm Industrial PP PVC S Wave Cooling Tower Fill Media

-

PVC PP Roll Type Round Cooling Tower Fill Media

-

20mm sheet space hanging cooling tower infill 1020mm PVC fill for cooling tower

-

cross flow cooling tower fill 0.38mm PVC sheet for cooling tower

-

factory price plastic PVC honeycomb sheets cooling tower fill packing

-

honeycomb heat exchangers cooling tower PVC fill element of dispersion system

Popular Searches

- frp cooling tower

- cooling tower

- water tower

- cooling tower infill

- spray nozzle

- plastic nozzle

- water spray nozzle

- spiral spray nozzle

- cooling tower system

- computer tower

- gas tower

- water cooling tower

- pp filler

- water nozzle

- cooling nozzle

- mist spray nozzle

- sprayer nozzle

- mixing nozzle

- industrial cooling tower

- frp cooling water tower

- pvc sheet infill

- aluminum tower

- tower 200

- counterflow cooling tower

- cooling tower fill

- bac

- pvc nozzle

- spiral jet nozzle

- industrial nozzle

- lift tower

Recommended Products

- high quality Square cooling tower wholesale price

- Good price Industrial FRP Counterflow Round Cooling Tower Supplier

- Good Price FRP Cross Flow industry square cooling tower supplier

- low noise counterflow FRP Industrial round cooling tower for chiller

- Open Type Cross Flow Industrial FRP Square Water Cooling Tower

- Produced by Jinggang Factory Industrial and commercial central air conditioning cooling towers

- Produced by Jinggang Commercial central air conditioning cooling tower and Cooling tower for casting cooling

- Produced by Jinggang Commercial central air conditioning cooling tower and DN1400 ammonia synthesis tower

- Produced by Jinggang Commercial central air conditioning cooling tower and Cooling tower for quenching production line cooling

- Produced by Jinggang Commercial central air conditioning cooling tower and Cooling tower for industrial furnace cooling

- Galvanized steel water tanks

- biochemical sponge filter

Find Similar Products By Category

- Industrial Equipment & Components > Refrigeration Equipment > Cooling Tower

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Hebei Lanyu Rubber & Plastic Products Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile