Home > Products > bkneddy2021 > Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

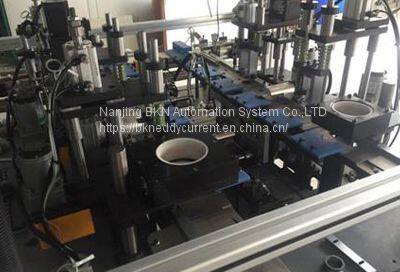

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

- T/T

You May Like

Product Description

The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a leading high-tech enterprise specializing in developing types of NDT non-destructive testing instruments and equipment in China. As one of the non destructive testing equipment suppliers, the company is committed to the development of eddy current, ultrasonic, magnetic flux leakage and various non-standard equipment, holding independent research and development of a number of national patents.

During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all defects.

The cause of the cracks in the bearing rings is complicated. From the raw materials to the finished products of the ferrules, if the process is not proper, the cracks may be directly caused or the hidden cracks may be buried for the occurrence of the lap ring grinding cracks.

There are many ways to form cracks in bearing rings: Raw material defects include: cracks in raw materials and the effects of raw material defects on the grinding process.

Forging defects include forging cracks, effects of forged microstructure defects on the grinding process, and cutter cracks. There are also various heat treatment defects and the like. Therefore, crack testing equipment and hardness testing are essential. BKN has considerable experience in crack detection, and Bearing Ring Crack and Hardness Combination testing equipment is a perfect combination.

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 Brief Introduction

Detection process

Vibrating plate and string charging →hardness test→crack detection→automatic blanking

Bad product sorting

Automatic charging —automatic detection—automatic sorting —automatic blanking

Crack detection(the probe uses stainless steel casing+nano abrasion material ) to ensure long-term normal of the probe

Crack sensitivity: a crack with a depth of ≥0.05 mm and a length of ≥1 mm extending inward from the surface of the ferrule; for a crack that has not extended to the surface inside the ferrule, when the thickness between the subcutaneous surface and the surface of the workpiece is ≤0.2 mm, the depth is ≥0.20 mm Cracks of length ≥ 1 mm can be detected.

Hardness sensitivity: Rockwell 1HRC ~ 2HRC (other parameters remain stable and consistent).

Contact Us

- Nanjing BKN Automation System Co.,LTD

- Contact nameLi HUI Chat Now

Product Categories

| bkneddycurrent | bkneddy2021 | Bkneddy001 |

New Products

-

Benchtop Magnetic Flux Leakage Testing Equipment

-

Drill Pipe Magnetic Flux Leakage Detector MFL-308

-

MFL101 Tank Floor MFL Scanner

-

Eddy Current Testing Equipment

-

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

-

BKNET-0102 Welded Pipe Eddy Current Flaw Detector

-

BKNET-101 Automatic Eddy Current Testing

-

Bolt Eddy Current Sorter BKNFX-11

-

Connecting Rod Hardness Eddy Current Sorting Machine LGYDFX-01

-

Eddy Current Testing for Auto Parts

-

Eddy Current Testing Equipment

-

BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Popular Searches

- testing machine

- ultrasonic transducer

- metal detector

- universal testing machine

- ultrasonic flaw detector

- flaw detector

- probe

- ultrasonic instrument

- ut

- pipe testing equipment

- test block

- crack detector

- ultrasonic testing equipment

- crack depth tester

- weld testing

- lcd color screen display

- crack testing tester

Recommended Products

- Double Aluminum Edge Gypsum Board Access Opening

- Concealed Gypsum Board Access Panel

- Gypsum Double Aluminum Edge Access Opening

- Flip-down Access Panel

- High Quality Acoustic Fiber Board Square Armstrong Ceiling Tile Factory Direct Sale

- Armstrong Mineral Fiber 60x60 60x120 Cm Wooden Board Mineral Fiber Ceiling Tile

- Acoustic Mineral Fiber Ceiling Suspended False Ceiling for Ceiling Tile

- Armstrong Ceiling T Grid & Mineral Fiber Ceiling Tile

- Wholesale Soundproofing Ceiling Mineral Fiberglass Ceiling Acoustical Tile Factory Glass Wool Ceiling Panel Like Armstrong Panel

- Modern Design Decorative Aluminum Expanded Metal Mesh Ceiling Panels for Office Buildings

- Mineral Wool Board Ceiling Panel Acoustical Baffle Ceiling for Decorative Sound Solution

- Soundproofing Ceiling Mineral Fiberglass Acoustical Tile Factory Glass Wool Panel Like Armstrong Panel

Find Similar Products By Category

- Construction & Decoration > Ceiling > Plasterboard Ceiling

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Li HUI

Hi there! Welcome to my shop. Let me know if you have any questions.

Li HUI

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile