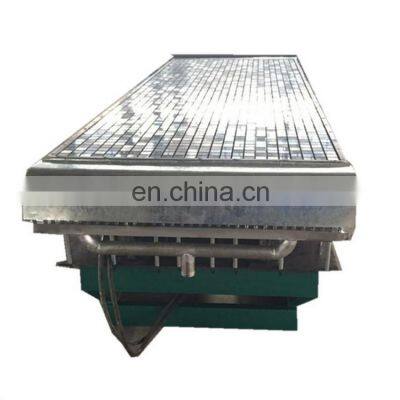

Fiberglass molded composite grating making machine FRP grating machine

Negotiable

1 (Min. Order)

- T/T Credit Card

You May Like

-

Factory Fiberglass GRP Grating Machinery FRP Molded Grating Machine

-

Best-Sell 20ton Hydraulic Pultrusion Machine FRP Pultrusion Equipment

-

Automatic GRP FRP Fiberglass Tank Filament Winding Machine

-

1220*3660mm frp grating machine fiberglass grating making machine

-

Filament Winding Machine for FRP/GRP pipe and Tank

-

FRP Fiberglass Filament Pipe Winding Machine with Automatic CNC Controlled

Product Description

Product Information

1220 * 4920 * 38mm FRP grating mold is a non-standard model of glass steel grille equipment, as the recent car gradually into the homes of ordinary people, around the car and car beauty shop in the ascendant. FRP grille in the field of caravans to promote, making the glass car grille market really formed, expanding the FRP grating has a new field. We have designed this specification in accordance with this form of equipment, because you can also in the direction of the length of the production of 3660 and 4000 grid plate, so the mold once listed, immediately received the majority of glass steel grille manufacturers of all ages. The following technical information on the equipment described below: to readers.

First, the mold forming surface size: 1220 * 4920 * 40, at the same times the production of arbitrary specifications of the card grille. For example: 1.22 * 3.66 or 1.22 * 4000 board can be produced.

Second, the module specifications: the upper end: 31.1 * 31.1, the lower end: 33.1 * 33.1, the module height of 40 mm. The size of the entire module deviation is not greater than 0.08 mm. Of course, we can also adjust the size of the module according to customer requirements, here omitted 50 words, you know!

Third, the module material and technology: the module selection of high-quality S45C die steel, after sawing cutting, grinding machine flat head, milling machine open oblique, grinding machine leveling, drilling, sanding chamfering, cloth wheel polishing, plating hard chrome and other 8 processes Into, which is the most attention to the module plating, to strictly accept the seventy-nine forty-nine minutes of plating, in the module surface to form 0.05-0.07 mm coating. The whole process gives us an exclusive tour of another version of a steel art tour.

Fourth, the product size: Center distance: 38.1 * 38.1, height: 38 mm, product ribs thickness, the next 5mm 7 mm. Products in the square meter in the 19.5 kg, material consumption, close porcelain real.

Fifth, the color: According to customer requirements for glass fiber reinforced plastic grating equipment, the general factory color for the general-purpose motor gray.

Six, roof thickness: 14mm, material S45C steel, roof surface milling machine trim, large-scale sanding machine high-speed polishing. Seven, bottom plate thickness: 14mm, material Q235A, large gantry milling machine planning. 8, the trip part: the stroke of the equipment is the central part of the movement of the mold, we use 25 mm thick S45C steel plate, after milling machine precision machining to ensure that the size of strict fit, combined with eight 45 mm square steel as the support, to ensure that the whole Stroke advance and retreat, smooth operation. Cylinder size diameter 110mm, length 350mm, cylinder pillow selection of wide Q235A forged steel, super pressure.

Nine, mold overall appearance: wide 1300 * long 5730 * high 850 mm. The height of the mold can be adjusted according to the grille production process selected by the customer. For example, choose a single pull the yarn customers; our mold height is generally not more than 750 mm.

Aavantages:

fast heating

strong operability

convenient installation

easy to operate and maintance

convenient installation

easy to operate and maintance

Water proof

High impact strenge

Fire registance

Resistant to acid / alkali fumes

Our FRP molded grating production line is made of following devices:

1) FRP Molded Grating Machine

2) Mixer Storage tank

4) Hydraulic pump

5) Grinding machine

6) Water-circulating pump

7) SS hot water tank

8) Air source heating pump

9) Cooling tower

We provide full set of FRP grating machines together with technology of producing if required.

Specification

No. | Mesh size(mm) | Grating panel size L*W*H(mm) | Module(mm) |

1 | 38*38 | 1220*3660*38 | 38.5-41 |

2 | 38*38 | 1220*3660*25 | 30.5-32 |

3 | 38*38 | 1220*3660*25 | 25.5-27 |

4 | 50*50 | 1220*3660*50 | 50.5-52 |

5 | 38*38 | 1000*4038*38 | 38.5-41 |

6 | 38*38 | 1000*4038*25 | 25.5-27 |

Cautions

Before use the new mold clean up oil stains and other dirt inside the mold.Before use the mold please check if the screws loose or not. If loose, please fasten in time.Keep the mold slide adequate oil, prohibit knocking the I beam steel with hammer. Spray the demoulding agent three times, spray the agent after curing the last spray.After producing 3-4 grating sheets spray the demolding agent to the mold. Produce after the agent drying. In the following production please spray the demolding agent periodically according to the actual conditions. Details Images

Our company

Hengshui Jiubo Composite Co., Ltd. (our factory) is professional manufacturer of FRP Pipe, FRP storage tank, FRP cooling tower, FRP molded products, FRP pultruded products and relative FRP production machines & technology, we have two international sales branches - Hengshui Aoliande Trading Co., Ltd. (our trade sales company) and Hengshui Gains Trade Co., Ltd, through the continuous development and introduction of professionality and technology, our company rely on advanced technology, exquisite craftsmanship, reliable quality and perfect service, passed ISO9001, ISO14001, OHSAS18001 management system certification, now we have 300 staff, annual sales of glass fiber reinforced plastic series products achieved 20,000 tons, products have been sold to all over the world, USA, Brazil, Japan, Germany, India, Malaysia, Egypt, Chile, Panama, Spain, etc., and won the support and trust from new & old customers.

Certifications

FAQ

1. Q: Are you Trading Company or Manufacturing Factory?

A: We are both manufacturer and trading company. We have our own factory for almost 10 years, and we have better service of overseas customers. Welcome to send your inquiry!

2. Q: How about the Delivery time?

A: Normally, 10-15 days to finish the order for a 20ft container. Welcome to ask for the detailed delivery time according to your order quantity!

3. Q: How can you guarantee the product quality?

A: We have the quality control system ISO9001:2015, and it's been followed strictly. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing.

4. Q: What is about the payment terms.

A: Basically, the payment terms are paypal, T/T, L/C at sight. Western Union, Alipay.

5. Q: Can you do OEM for me?

A: We accept all OEM orders, just contact us and give me your design,we will offer you a reasonable price ASAP.

Related Products

Contact Us

- Hengshui Aoliande Trading Co., Ltd.

Product Categories

| Drainage ditch | Electrolytic cell | FRP cooling tower | FRP grating |

| FRP PIPE | FRP pultruded profiles | FRP storage tank | FRP tower equipment |

| Machine | Septic tank | SMC | Ungrouped |

| Water tank |

New Products

-

FRP Pultrusion Machine for Glass Fiber Reinforced Plastics

-

Factory supply Carbon fiber pultrusion machine Fiberglass machine

-

China factory supply Fiberglass rebar machine, Basalt rebar production line

-

Automatic FRP GRP Pipe production line, Pipe winding machine

-

High Quality Automatic FRP Sheet Pultrusion machine for frp rebar

-

Wholesale Frp Molded Grating Making Machine,Glass fiber grating production line

-

Filament Winding Machine for FRP Pipe or tanks grp pipe machine

-

GRP Fiberglass Profile Rebar Pultrusion Machine/FRP Tube Anchor Rod Making Machine

-

China Factory Frp Molded Grating Machine,grating manufacturing machines

-

20ton frp Pultrusion Machines for FRP pultruded Profiles

-

Complete grp pipe production line Filament winding machine pipe making machinery

-

Automatic GRP FRP horizontal Tank Production line Fiberglass Tank Winding Machine

-

FRP/Fiberglass Molded Grating Machine with Panel Size 1220X3660X38mm

-

Composite Grating Pultruded Fiberglass Grating Making Machine

-

China Manufacturer FRP Grid Molded Grating Making Machine Fiberglass Grate

-

FRP GRP Fiberglass Pultrusion Machine for various frp Profile

-

FRP GRP Fiberglass Grating Machine Molded Grating Equipment FRP Grating Production Line

-

CNC Filament Winding Machine for FRP Tanks Automatic FRP GRP Tank Winding Machine

-

Grating machine for fiber glass, grating machine for fiberglass

-

fiberglass grating machine frp grating mold manufacturer frp grating machine

-

Hydrostatic water pressure test machine for GRP FRP pipe hydrostatic test equipment for grp frp pipe

-

Hydrostatic Tester for Pipe grp pipe hydro testing equipment

-

Corrosion resistance High property FRP molded grating machine

-

The module using delicate 45# steel, grinding FRP molded grating machine

Popular Searches

- wall board machine

- pile concrete

- concrete form machine

- Button Heading Machine

- eps panel line

- laminate plant

- leca production line

- pre machines

- product postings

- products postings

- precast prestress concrete

- purling machine

- precast hollow core slab

- roof pannel

- sale installer

- sales installer

- drawer slides roll forming machine

- automatic rock

- brand installer

- board machin

- board equipements

- corrugate asbestos

- light expanded clay aggregate

- discontinuous pu line

- eps coating

- factory installer

- line panel

- brown fullness machine

- grage

- line shelves

Recommended Products

- Mineral Stone Basalt Panel Making Machine Stone wool Production Line Natural Gas Basalt Rock Wool Making Machine

- gypsum board laminating machine gypsum tiles making machine

- rock wool making machine rock wool machine stone wool making machine

- stone wool production line mineral wool production line rock wool production line

- pur/pvc laminated hot glue press machine pur foil laminating machine pur 1300 lamination machine

- small floor mgo board production line board making manufacturing machine

- small scale gypsum board lamination machine 600*600 gypsum ceiling tiles making machine

- automatic rock wool production line rock basalt mineral wool production line rock wool line production

- small capacity 60x60 pvc laminated gypsum ceiling tiles board laminating making machine production line

- full automatic gypsum board perforating machine gypsum board punching machine

- Pneumatic spray machine Steel structure special multi-functional high pressure airless spray machine environmental protection and paint saving

- Concrete mixing station machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Board Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Hengshui Aoliande Trading Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile