Home > Products > bkneddy2021 > Magnetic Flux Leakage Testing Equipment

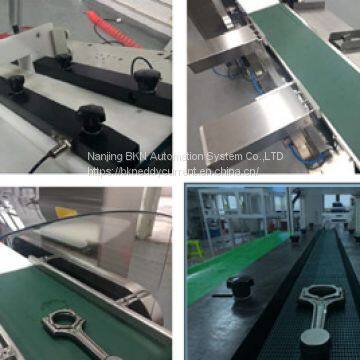

Magnetic Flux Leakage Testing Equipment

- 5000 Bag / Bags per Month

- T/T

You May Like

Product Description

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testing is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

The basic magnetic flux leakage principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI magnetic flux leakage testing method is a highly automated magnetic flux testing technology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage ndt detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

BKN is a professuonal mfl suppliers, we provide ndt testing machine, magnetic flux leakage sensor, ndt testing, etc. Want to know what is magnetic flux leakage or magnetic flux leakage testing procedure? Please contact us.

Contact Us

- Nanjing BKN Automation System Co.,LTD

- Contact nameLi HUI Chat Now

Product Categories

| bkneddycurrent | bkneddy2021 | Bkneddy001 |

New Products

-

BKNET-101 Automatic Eddy Current Testing

-

Bolt Eddy Current Sorter BKNFX-11

-

EDM Notch

-

RQ-120-B Automatic CNC EDM Notch

-

Magnetic Flux Leakage Testing Equipment

-

Benchtop Magnetic Flux Leakage Testing Equipment

-

Drill Pipe Magnetic Flux Leakage Detector MFL-308

-

MFL101 Tank Floor MFL Scanner

-

Eddy Current Testing Equipment

-

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

-

BKNET-0102 Welded Pipe Eddy Current Flaw Detector

-

BKNET-101 Automatic Eddy Current Testing

Popular Searches

- ceiling board

- Ceilings

- ceiling panel

- pvc ceiling

- suspended ceiling

- ceiling decoration

- False Ceiling

- Aluminum Ceiling

- Baffle Ceiling

- Wpc Ceiling

- Panel Ceiling

- Gypsum Board Ceiling

- Metal Ceiling

- Decorative Ceiling

- Heat Insulation Board

- edge board

- Drywall

- gypsum board

- plasterboard

- gypsum

- gypsum plasterboard

- plaster drywall

- Gypsum Board Plasterboard Drywall

- Ceiling Board Drywall

- Plasterboard Ceiling Drywall

- Ceiling Material

- drywall board

- Mineral Wool Board

- Mineral Wool Ceiling Board

- Paperboard

Recommended Products

- 3d Design Office Slat False Ceilings Interior Decor Metal Aluminum Wood Grain Suspended Ceiling

- Polyester sound-absorbing board/Polyester felt

- Perforated Mineral Fiber Ceiling Slab Board

- White Sound Acoustic Square Mineral Fiber Ceiling False Ceilings

- Sound Absorption Mineral Wool Ceiling Board

- Public Decoration Mineral Wool Ceiling Board

- Mineral Wool Ceiling Board Manufacturers

- Mineral Fibre Board Ceiling For Suspension System

- Mineral Fibre Board Ceiling For Suspension System

- Mineral Fiber False Ceiling Plate For Commercial

- Mineral Fiber Ceiling Tiles With Suspended Systems Acoustic Ceiling Board

- Mineral Fiber Acoustic Suspended Ceiling Ceiling Panels Acoustic Ceiling Panels

Find Similar Products By Category

- Construction & Decoration > Ceiling > Plasterboard Ceiling

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Li HUI

Hi there! Welcome to my shop. Let me know if you have any questions.

Li HUI

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile