Home > Products > Pipe Extrusion Lines > Xinrong dust free knife cutter HDPE pipe extruder machine with PLC control system

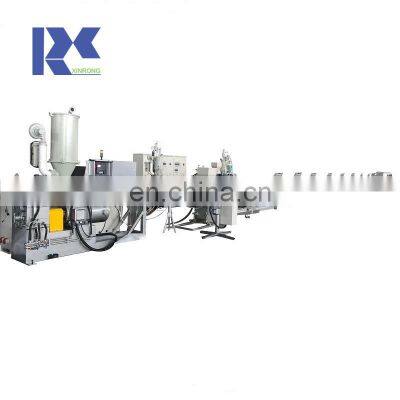

Xinrong dust free knife cutter HDPE pipe extruder machine with PLC control system

Negotiable

1 (Min. Order)

- T/T Credit Card

You May Like

-

Xinrong plastic extruder pipe producing line hdpe pipe production extrusion line

-

Xinrong fully automatic pipe extruders plastic PVC double pipe extrusion machine line

-

XINRONG 3-layers PPR HDPE Pipe Making Machine Plant Extrusion Line Producer manufacturer

-

XINRONG 16~630mm pvc pipe making machine price/pvc pipe extrusion machine

-

xinrong best sell plastic pvc water pipe production plant making machine with price

-

xinrong cpvc pipe extruder pipe making machine pvc

Product Description

Product Description

PE PP Pipe Extrusion Machine

Main Technical Features

1. PE pipe extrusion lineis developed by XinRong based on European advanced technology and R&D experience of the plastic machinery for many years. Advanced design, reasonable structure, high reliability, high degree automation of the complete line.

2. Extruder with special barrel feeding structure can largely improve extrusion capacity.

3. Accurate temperature control, good plasticization, stable operation.

4. The complete line adopts PLC control system, realizing synchronization and automation.

5. Human-computer interface is easy to operate, convenient and reliable.

6. Spiral and lattice basket type die head for choice.

7.Dust-free knife cutter and saw cutter for choice.

8.Changing some parts of the line can also realize two-layer and multi-layer co-extrusion.

9.Changing some parts of the line can also produce PP, PB pipes.

2. Extruder with special barrel feeding structure can largely improve extrusion capacity.

3. Accurate temperature control, good plasticization, stable operation.

4. The complete line adopts PLC control system, realizing synchronization and automation.

5. Human-computer interface is easy to operate, convenient and reliable.

6. Spiral and lattice basket type die head for choice.

7.Dust-free knife cutter and saw cutter for choice.

8.Changing some parts of the line can also realize two-layer and multi-layer co-extrusion.

9.Changing some parts of the line can also produce PP, PB pipes.

Model | Pipe range(mm) | Haul-off speed(m/min) | Total Length(m) | 0utput capacity(kg/h) | total power(kw) |

PE63 | 16-63 | 1.2-12 | 35 | 80~120 | 110 |

PE110 | 20-110 | 1.0-10 | 38 | 150~250 | 163 |

PE160 | 50-160 | 0.8-8 | 40 | 200~250 | 169 |

PE250 | 75-250 | 0.38-3.8 | 42 | 250~350 | 214 |

PE315 | 90-315 | 0.3-3 | 44 | 300~350 | 245 |

PE450 | 110-450 | 0.2-2.0 | 56 | 350~450 | 356 |

PE630 | 250-630 | 0.1-1.0 | 62 | 700~800 | 563 |

PE800 | 315-800 | 0.07-0.7 | 68 | 900~1100 | 740 |

PE1000 | 400-1000 | 0.06-0.6 | 70 | 1000~1100 | 800 |

PE1200 | 500-1200 | 0.05-0.5 | 72 | 1000~1300 | 927 |

PE1600 | 710-1600 | 0.04-0.4 | 74 | 1200~1500 | 1069 |

Detailed Images

Single Screw Extruder

Advanced overall design of direct combination. Efficient screw and spiral water cooling sleeve in barrel, can realize extruding material in low melt temperature in high speed.

Relation between capacity and screw rotation speed is nearly linear, stable extrusion, high reliability, easy for operation.

Relation between capacity and screw rotation speed is nearly linear, stable extrusion, high reliability, easy for operation.

Extrusion Die Head

Die head structure: Spiral type , Ensure melt temperature uniformity, thoroughly eliminate confluence seam and reduce flaws such as bubble, black spot, unsmooth inside wall, caused by too high temperature.

Material: 40Cr, forgings with tempering treatment

Bolt grade: 12.9 grade high strength bolt

Material: 40Cr, forgings with tempering treatment

Bolt grade: 12.9 grade high strength bolt

Vacuum Tank

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. Its shape is advanced foreign multilateral anti-deformation structure. The cover is made of high quality casting aluminum alloy.

Its inside is double-chamber structure. The pipeline adopts the design of double loop pipeline, realizing non-stop pipeline clean and function of temperature control.

Cooling Tank

Supporter structure are similar with foreign advanced machine and convenient to observe spray effect.

Caterpillar Haul-off Machine

Its structure with sliding tempering glass door is beautiful and practical. Traction device with V type rubber block caterpillar and controlled by imported inverter can steadily haul pipe. It also features compact structure and free-maintenance.

Adopt special automobile drive shaft to transmit power, stable and reliable. Length measuring device equipped with a rotary encoder, can ensure precise cutting, customer can set the cutting length.

Adopt special automobile drive shaft to transmit power, stable and reliable. Length measuring device equipped with a rotary encoder, can ensure precise cutting, customer can set the cutting length.

Cutter

Its structure is beautiful and practical with glass window glass. Cutting process is conrolled by PLC, can realize accurately arbitary length cutting.

Stacker

Company

Why choose us?

1. Quality

We have more than 23 years manufacturing experience with more than 800 sets machine lines sold to worldwide. We have our own CNC center to produce machine parts. And control the machine quality from the order confirm to engineers discuss & design, machine processing, testing and delivery. We are one of the Top10 manufacturers for this business in China.

2. Price

Machine price determines your end product cost. Our machine price can make you earn back equipment investment in 2-3 months. We do not sell the cheapest machine, just good quality at good price.

3. Service

We provide turnkey project and completely pre-sales and after-sales service, including project feasibility analysis, installation, commissioning and training.

commissioning and training.

1. Quality

We have more than 23 years manufacturing experience with more than 800 sets machine lines sold to worldwide. We have our own CNC center to produce machine parts. And control the machine quality from the order confirm to engineers discuss & design, machine processing, testing and delivery. We are one of the Top10 manufacturers for this business in China.

2. Price

Machine price determines your end product cost. Our machine price can make you earn back equipment investment in 2-3 months. We do not sell the cheapest machine, just good quality at good price.

3. Service

We provide turnkey project and completely pre-sales and after-sales service, including project feasibility analysis, installation, commissioning and training.

commissioning and training.

Certifications

Installation Instructions

Arrangement for inspection, installation and testing work

1. After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply,water supply, raw material,labors and cranes, etc.

2.We will prepare the visa for our engineers, who are responsible for guiding of machine installation and testing at the factory.

3.The buyer should bear the round-trip air ticket for engineer if visa application is approved. The buyer is also responsible tobear expenses generated according to local conditions, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

4.Engineer will give free training lessons to labors in buyer’s factory.

1. After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply,water supply, raw material,labors and cranes, etc.

2.We will prepare the visa for our engineers, who are responsible for guiding of machine installation and testing at the factory.

3.The buyer should bear the round-trip air ticket for engineer if visa application is approved. The buyer is also responsible tobear expenses generated according to local conditions, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

4.Engineer will give free training lessons to labors in buyer’s factory.

Packing & Delivery

Trade terms

1.Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

2.Delivery Time: 40 days after receipt of prepayment.

3.Packing Method: Packing film or wooden case

4.Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE

1.When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine isok, then client pay for the balance. And inspect machine load the container.

2.When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine

installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

3.If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24hours.

1.Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

2.Delivery Time: 40 days after receipt of prepayment.

3.Packing Method: Packing film or wooden case

4.Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE

1.When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine isok, then client pay for the balance. And inspect machine load the container.

2.When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine

installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

3.If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24hours.

Contact Us

- Jiangsu Xinrong Science & Technology Development Co., Ltd.

Product Categories

| Auxiliary machines | Meltblown machine | Pipe Extrusion Lines | Plastic Recycling And Granulating Line |

| Profile Extrusion Lines | Sheet/board Extrusion Lines | Ungrouped |

New Products

-

large diameter pe pipe production line polyethylene pe pipe machine plastis pe pipe extrusion line

-

zhangjiagang pe pipe production line plastic ppr pipe manufacturing extrusion equipment machine

-

20~110mm pe pipe extrusion line making machine production line

-

small diameter pvc pipe making machine pvc garden tube/house plastic pipe equipment

-

plastic PE double wall corrugated pipe making machine with good quality

-

plastic hdpe pipe extruder ppr plastic pipe making equipment

-

PP/PE single wall corrugated pipe extrusion machine line

-

PVC pipe making machinery plastic pipe production machine with price

-

plastic pipe extrusion equipment for pe double wall corrugated pipe making production machine

-

PE plastic double wall corrugated pipe making production machine for sale

-

630 mm drainage pipe processing extruder pe drainage pipe machine

-

plastic large diameter hdpe drainage pipe line for hollow wall winding pipe extrusion machine

-

hdpe pe water gas pipe extrusion making machine manufacturers ppr plastic pipe making equipment

-

HDPE 1200 production line plastic dwc corrugated pipe machine plastic equipment for pipes

-

HDPE 1200 pipe extruder equipment for corrugated pipe pp drainage pipe producing machinery

-

zhangjiagang plastic pipe machine HDPE 1200 double wall pipe producing equipment

-

hdpe double wall corrugated pipe extruder double wall corrugated pipe extrusion equipment

-

HDPE 1200 pipe extruder corrugated sewage pipe equipment

-

aluminum ppr pipe extrusion line aluminum and plastic composite pipe machinery

-

China supplier PVC pipe machine manufacturer plant

-

Best quality pvc plastic pipe extruder with planetary cutter

-

plastic composite pp pipe processing making extruder machinery

-

1200mm size pe pp corrugated pipe line with pipe forming machine

-

pvc drainage pipe extrusion machine for plumbing

Popular Searches

- plastic extruder

- extrusion machine

- twin screw extruder

- aluminum tube production line

- Foam Board Equipment

- production line

- extruding machine

- Production Equipment

- extrusion line

- Belt Making Machinery

- Extruder Machine

- Pet Strap Making Machine

- Pet Belt Making Machine

- Bubble Film Making Machine

- Cable Manufacturing Equipment

- plastic extrusion

- plastic machinery

- extruding equipment

- wire extruder

- cable extruding line

- Cable Extruder Machine

- Cable Manufacturing Machine

- decorative line

- Extrusion Production Line

- Engineering Lab Equipment

- eps machinery

- cement production line

- pipe making machine

- pipe production line

- Board Making Machine

Recommended Products

- xps foam board production line

- HDPE Pipe Production Line

- Petrochemical Granulation Equipment Use Polyolefin Pelletizing Die Plate

- Spare Parts Pelletizing Knife Holder Used for Granulating Polymer

- Spare Parts for Fixing Pelletizer Knives Pelletizing Cutting Disc

- PP PE underwater granulation system use knife rotor

- Industrial Cutting Blade for Underwater Pelletizing Unit for Plastic Granules Manufacturing

- Intensive Heated Channel Die Plate for Producing PP PE Particles

- Underwater Pelletizing Unit Use Pelletizing Blade for Plastic Granules

- Pelletizing Die Plate for Underwater Polyethylene Pelletizing System Extruder

- Metal-ceramic Composit Pelletizer Knife for PP PE Plastic Granule Extruding

- Flexible Pelletizer Knife Holder for Underwater Cutting Plastic Granules Line Carrier for Pelletizer Knives

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Extruder

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Jiangsu Xinrong Science & Technology Development Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile