Home > Products > PRODUCTION LINE > ARTIFICIAL LEATHER PUV PU SUBSTRAT CLOTH MACHINE LINE SOLUTION FOR NONWOVEN

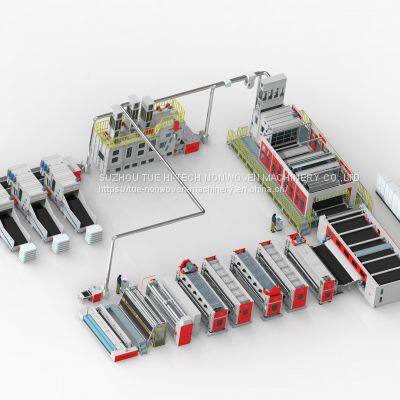

ARTIFICIAL LEATHER PUV PU SUBSTRAT CLOTH MACHINE LINE SOLUTION FOR NONWOVEN

- SHANGHAI

- T/T L/C

You May Like

Product Details

| Brand Name | TUE HI-TECH | Place of Origin | China | |

| Model Number | / | Certification | UR,UL,ISO9001 | |

| After-sales Service Provided | Engineers available to service machinery overseas | Warranty | 1Year | |

| Weight | 200000 | Dimension(L*W*H) | CUSTOMIZED | |

| Condition | New | Voltage | 220V/380V/415v/440v | |

| Power(W) | customization | Automatic Grade | Automatic |

Product Description

ARTIFICIAL LEATHER PUV PU SUBSTRAT CLOTH MACHINE LINE SOLUTION FOR NONWOVEN

T.U.E HI TECH located in Zhitang Industrial Park, which is a famous nonwoven equipment town in China, covering an area of 46,000 square meter. We offer a complete solution for all the Nonwovens from the fiber opening, web forming and laying to the bonding followed by the finishing so as to comply the final fabric as per customer’s requirement.

With integrated manufacturing, we try our best to supply entire production line for a wide range of industries: Automotive, Housings, Acoustic and Thermal Insulation, Geotextiles, Filtration, Artificial leather, mattress felts for bedding & furniture and Cleaning wipes, medicals, Flooring etc

With the advancement in the technology and the development of the Nonwoven needs of the users, TUE HI-TECH always tries to upgrade and cope up with the change. Equipped with numerous equipment’s like CNC machines, Drilling machine, Automated computerized Needling, Boring-milling technology, Inspection systems, laser-plasma cutting machines, safe painting and air filtering to safeguard environment, TUE HI-TECH is duly serving all our Nonwoven users with consistent quality and reliable manufacturing ensuring precision in every work we undertake.

TECHNICAL PARAMETER:

Name | 2021 Hot Sale Artificial Leather Production Line For Nonwoven leather bag substrate fabric base |

Working width | 3600m,2500mm,4500mm |

Machine size(mm) | Estimated 28*26M based on 6.6m working width |

Weight Control | PLC |

Precision(%) | <3 |

Capacity (kg/h) | 150-300 kg per hour |

Motor brand | Siemens-Beide, Made in China |

| Inverter brand | Siemens |

Working Processing

Needle felts used as suede are manufactured using card and cross lapper. To achieve a high uniformity from the outset, very fine polyester staple fiber(1-3 dtex) are prepared with the aid of a fine opening stage (Multi Feed). The card feeder forms a compact uniform mat of fiber flocks which is then fed to the card. The weight of this mat is adjusted with the help of either a belt weighing control device. A carding with three or four worker/stripper pairs on the breast cylinder and five more on the main cylinder card fiber flocks thoroughly. A cross lapper lays the web layers on top of each other with exact matching of the edges and creates the final weight. A very good surface quality for the production of suede products is achieved by needling the needle felt in up to 10 stages.

Bale Opener------Pre Opener------Main opener------Hopper Feeder------Carding Machine------Cross lapper------Needle punching(5 or 7 sets of needle loom)------Calender------Winding

Final Fabric and Application:

Synthetic or artificial leather is a textile made of man-made fibres which is produced to imitate the characteristics of real leather. Needlefelts are used for the base material before coating or as artificial suede.Application:

Shoe upper material

Funiture upholstery material

Handbags

Apparel

Quality Assurance

Inhouse Production

Branded parts and electrical components

Warranty to the parts

24x7 Customer Service

Pre- Shipment Inspection

Quality Control from Raw material- processing - assembling- packing and loading - Installation- Comissioning- Final Setup

How do we pack the machines?

Packing before shipment is a considerable effort for us where we always care for the safety of the machines.

1. Draw machine packing chart before loading the machine.

2.Segregate the machines to load them with ease after the successful trial and testing of the machine.

3.Wrap the machines with felts and wound films to ensure the safety of the machines and avoid any breakage due to jolting of the vehicles. ( Truck or Ship)

4.Spare parts are kept in the wooden case to avoid breakage.

5.Note the details of the machines after loading in each containers and make the descriptive details of containers which is then forwarded to customers for their reference.

What we do for YOU?

1.Upgrade your current line giving solutions to the problems you encountered.

2.If you are New in the market, we provide you Professional Consultation Service and Guidance based on your intended product. Assureyou with the testing or trial before shipment, so that you can witness the real time production and necessary adjustments shall be carried out on your Interests.

3.If you are planning to Increase your production scale, Let us know your requirements ( Intended product, Capacity, Density and Raw material)

We avail you the Production layout of the new line for your reference.

1.What is your main product?

All range of nonwoven machines like for geo-textile, artificial leather fabric, thermal bonding fabric, carpets, fabric for automotives, waste felt, mattress, acoustic insulating material with needle punching, oven, and the new and advanced air-laid technology.

2. Why to trust TUE HI-TECH Technology?

In 3 years of serving our customers, we have exported around 200sets of machines, 10 countries, including USA, Mexico, Belarus, Russia, India, Pakistan, Nepal and some other south-east countries and have received very few complaints regarding malfunctioning or problems encountered with our machines.

The warranty period we provide our customers defines our sincerity for the service. The use of famous brands from France, Germany, Taiwan and Korea for the mechanical and electrical parts have always led us insure the quality.

As we value customer service, we always work hard to provide better after sales service availing our valued customers with the real time solutions to the problems they encounter.

The suggestions and feedback from our valued customers have always helped us update the technology. Thus, the updated technology always drives us to be dynamic.

3.Where are you Located?

We are located in Changshu city, 2 hours from Shanghai (60 Km away from Shanghai). No.6 Dingxin Road, Zhitang Town, Changshu, Jiangsu, China.

4.What defines your superiority?

Foundation Credibility,Quality Assurance, Updated Technology, Branded Parts ( Mechanical and Electrical) , Innovation, Dynamism in Work Force, Well defined administrative system, After-salesservice, Accurate documentation, Good Communication, 24X7 availability with Real time Solutions to serve our customers, warranty for the machines.

5.What is the warranty period for your machines?

We assure you with:

a. One year warrantee (guarantee) for the whole line.

b.Three years warrantee (guarantee) for machine frame/cylinder doffer roller/needle loom frame and main shaft.

Note: The opening drumcarding wiresneedlesbeltsdriving parts not include in guarantee time

Contact Us

- SUZHOU TUE HI-TECH NONWOVEN MACHINERY CO.,LTD

- Contact nameArati Bhatta Chat Now

- Addresschangshu, Suzhou, Jiangsu

Product Categories

| PRODUCTION LINE | OPENING AND BLENDING | CARDING AND WEB FORMING | Needle puching machine |

Popular Searches

- sofa fabric

- pu leather

- pu synthetic leather

- shoes material

- synthetic leather

- Faux Leather

- Bag Leather

- Pvc Synthetic Leather

- Pvc Artificial Leather

- Leather Fabric

- Pu Pvc Leather

- eco friendly

- environmental protection

- shoe leather

- furniture leather

- semi-pu

- leatheroid

- pvc leather cloth

- leather material

- Pu Artificial Leather

- sofa leather

- leatherette

- pvc leather stocklot

Recommended Products

- Full Servo Automatic Wet Wipe Machine

- Full Automatic Menstrual Pants Production Line Disposal Menstrual Pad Making Machine from Fujian

- Welldone Hot Sale T Shape Full Servo Automatic Baby Diaper Machine

- Customized Manufacture Full Servo Two Pieces Pull Up Machine

- Automatic Sanitary Napkin Machine Woman Sanitary Napkins Lady Pad Making Machine

- Welldone Hot Sale T Shape Full Servo Automatic Baby Diaper Machine

- Hygiene Equipment Elder Nursing Care Pad Underpad Manufacturing Machine

- Full Servo Automatic pull up Adult Diapers making machine For Manufacturing adult diaper pants production line

- Semi Servo Disposal Baby Diaper Making Machine Prix In China

- Full Servo Menstrual Pants Production Line Disposal Menstrual Pad Making Machine

- Full automatic Baby Diaper packaging machine Full automatic diaper packing machine

- Adhesive Glue Machine For Baby Diaper Machine Production Usage

Find Similar Products By Category

- Manufacturing & Processing Machinery > Textile Machinery & Parts > Nonwoven Machine

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Arati Bhatta

Hi there! Welcome to my shop. Let me know if you have any questions.

Arati Bhatta

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile